High-gradient magnetic separator

A high-gradient magnetic separator and sorting technology, which is applied in the direction of high-gradient magnetic separator, etc., can solve the problems of the difficulty of the next operation, the reduction of the processing capacity of the equipment, and the deterioration of the unloading effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

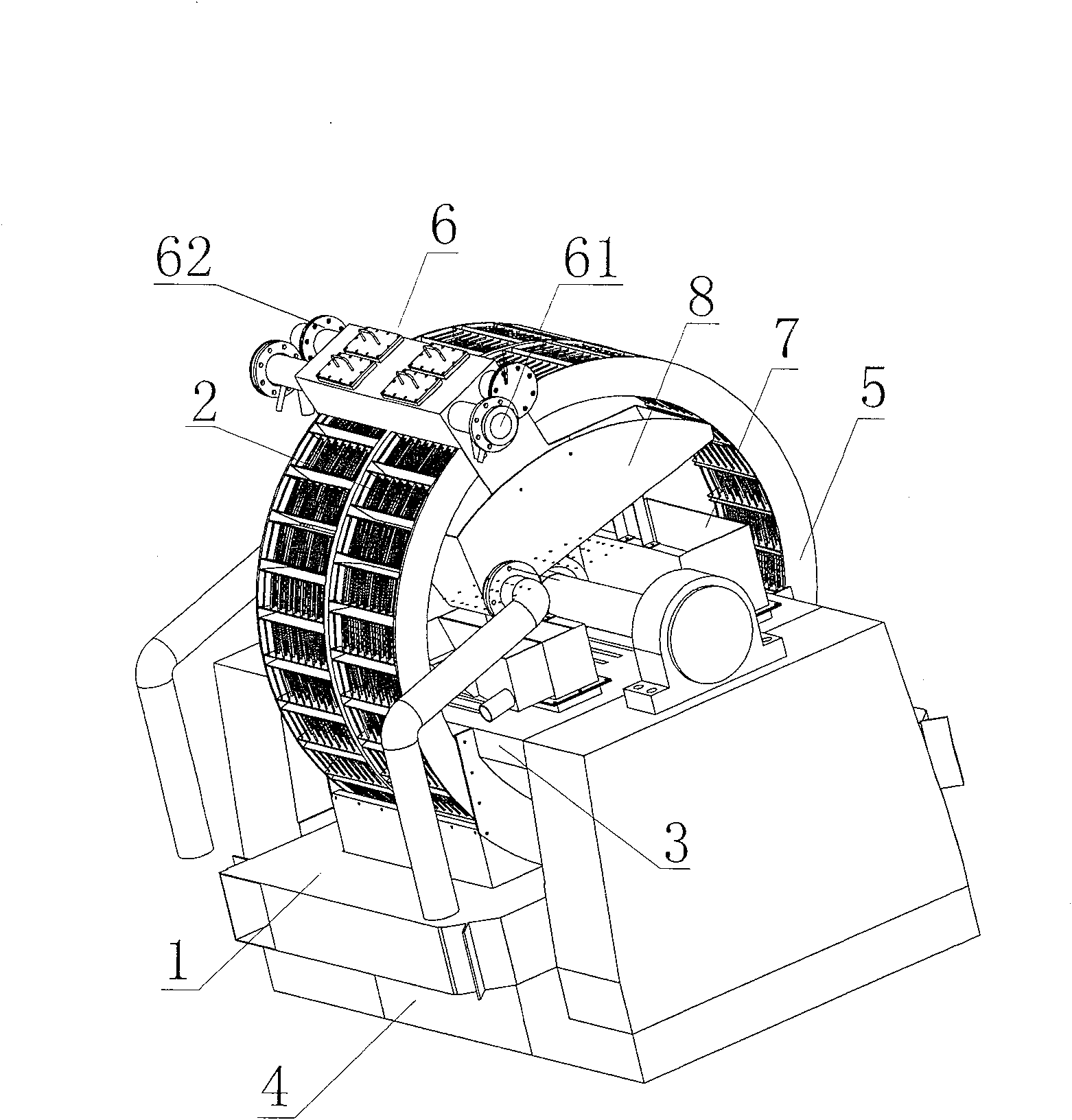

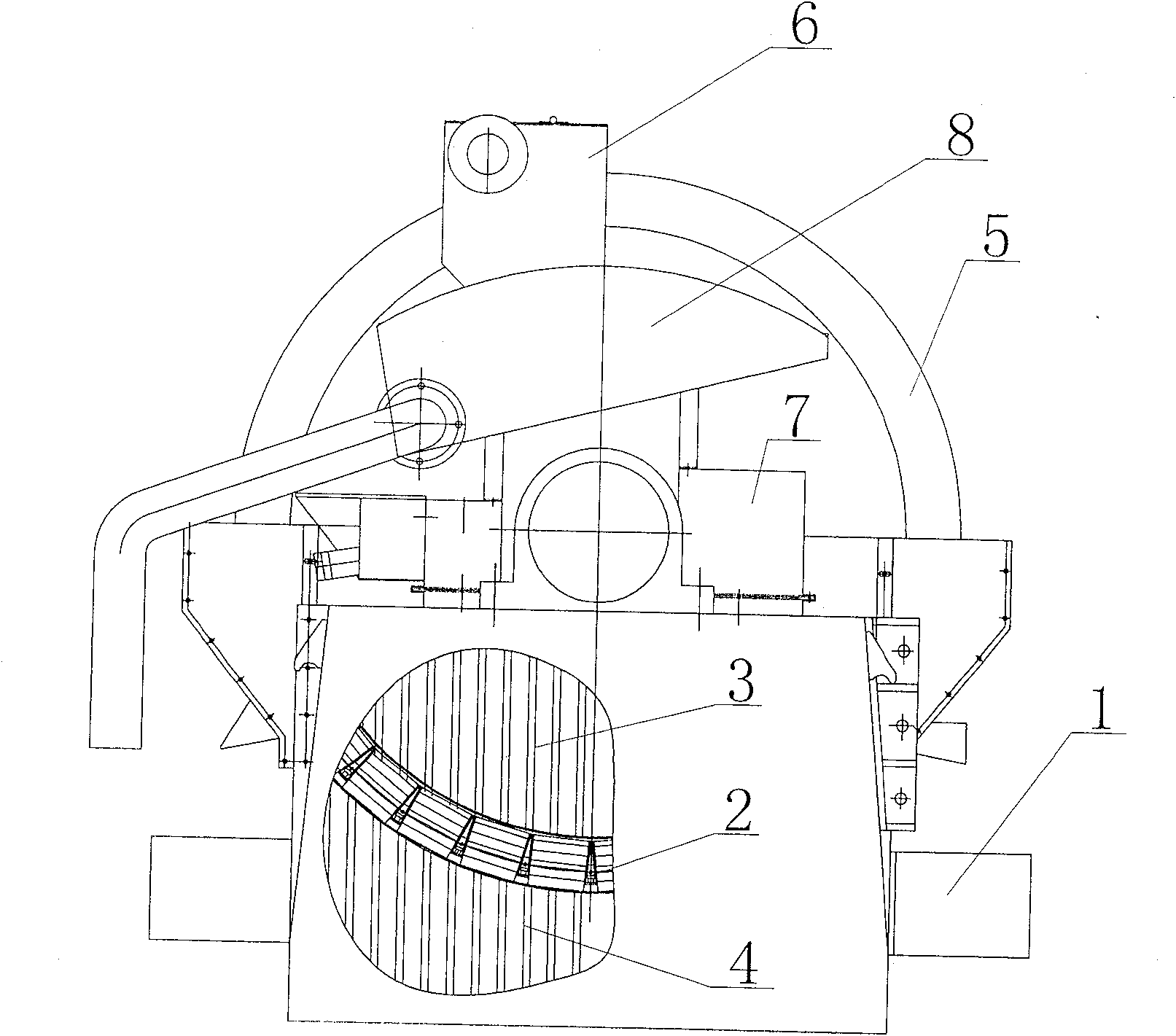

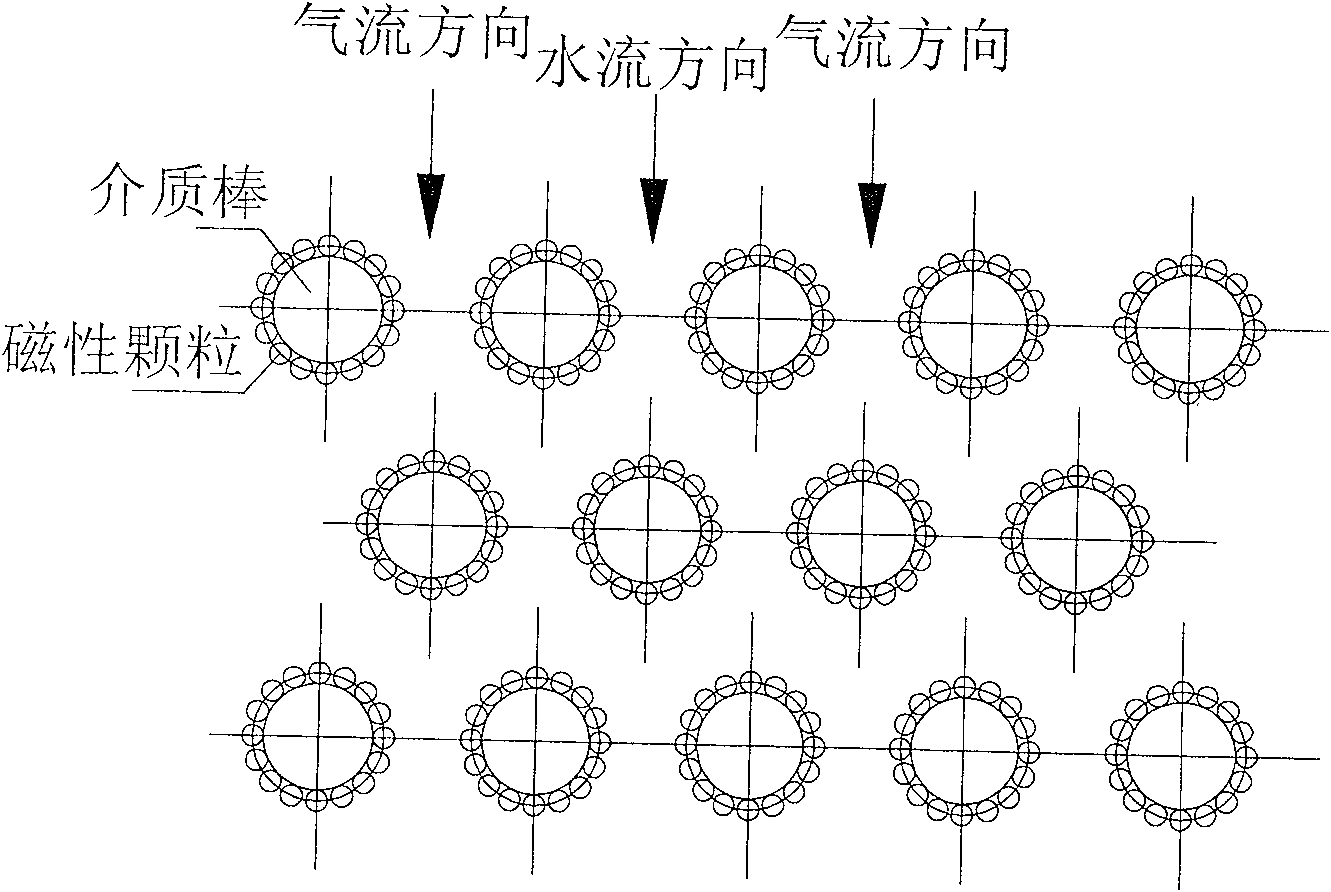

[0014] Such as Figure 1 ~ Figure 3 As shown, a high-gradient magnetic separator according to the present invention includes a separation ring and its driving device, a ore feeding device 7, a concentrate unloading device 6, and a concentrate collection device 8, wherein the separation ring includes a rotating ring 5 and the magnetizing medium stack installed on the rotating ring 5, the upper magnetic pole 3 located inside the rotating ring 5, the lower magnetic pole 4 located outside the rotating ring 5, and the excitation coil group 1, wherein the rotating ring 5 has a vertical double-ring structure, A turntable is arranged between the rings to connect the double rings as a whole. A shaft sleeve equipped with bearings is arranged in the turntable. The above-mentioned ring body is divided into a number of spaces of the same volume by a number of partitions, and the magnetic gathering medium stack is fixed in the corresponding space. The above-mentioned magnetic gathering medium st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com