Method for improving iron and reducing phosphorus of high phosphorus oolitic iron ore by magnetic roasting and two-step bioleaching

A technology of magnetization roasting and bioleaching, which is applied in the direction of improving process efficiency, etc., can solve the problems of long iron ore immersion time, high sulfur content in iron ore, and poor phosphorus removal effect, so as to reduce adverse effects and reduce sulfur Content, the effect of reducing the consumption of acid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

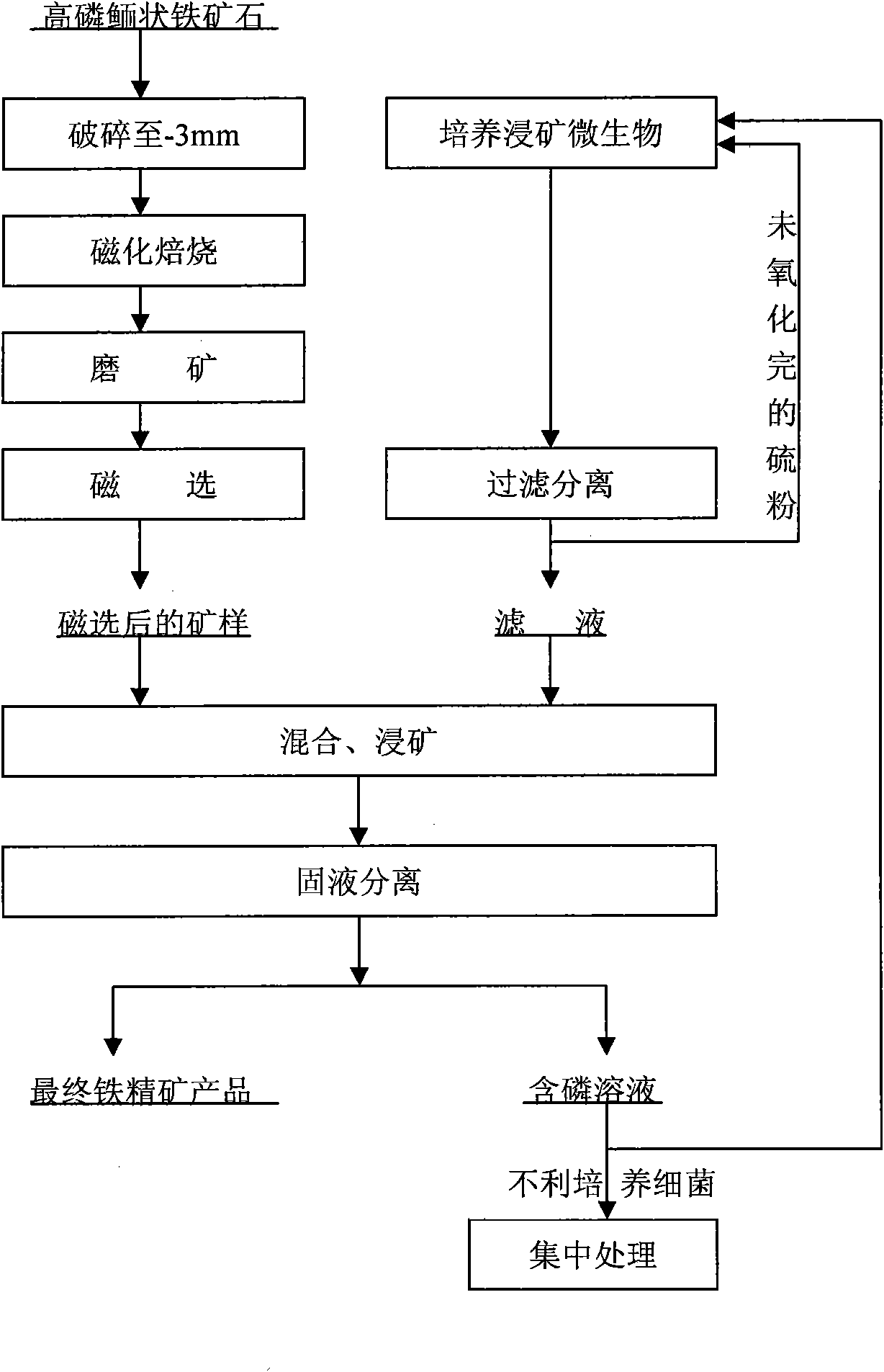

[0019] Embodiment 1, referring to the accompanying drawings, the high-phosphorus oolitic iron ore with an iron grade of 43.50%, a phosphorus content of 0.85%, and a sulfur content of 0.016% is crushed to a particle size of -3 mm, and magnetized in a box-type resistance furnace Roasting, the roasting temperature is 850°C, the roasting time is 25min, the amount of reducing agent is 5% of the weight of the ore, and then after the ore is ground to -74μm, it is magnetically separated by a weak magnetic separator under the condition of a magnetic field strength of 1500Oe. The ore samples were subjected to microbial leaching tests. The microorganisms used for ore leaching are acidophilic Thiobacillus ferrooxidans (At.f bacteria). The microorganisms used for ore leaching are first cultivated in the bioreactor, and the inoculation amount is 10% of the medium volume, and the bacterial concentration is 10% during inoculation. 8 ~10 9 cpu / ml, then add 4% ferrous sulfate according to the ...

Embodiment 2

[0020] Embodiment 2, referring to the accompanying drawings, the iron grade is 43.50%, the phosphorus content is 0.85%, and the sulfur content is 0.016% high-phosphorus oolitic iron ore is crushed to a particle size of -3mm, and magnetized in a box-type resistance furnace Roasting, the roasting temperature is 850°C, the roasting time is 25min, the amount of reducing agent is 5% of the weight of the ore, and then after the ore is ground to -74μm, it is magnetically separated by a weak magnetic separator under the condition of a magnetic field strength of 1500Oe. The ore samples were subjected to microbial leaching tests. The microorganisms used for ore leaching are At.f bacteria, and the microorganisms used for ore leaching are first cultivated in the bioreactor, the inoculation amount is 10% by volume, and the bacterial concentration is 10% when inoculating. 8 ~10 9cpu / ml, then add 1% sulfur powder according to the liquid mass ratio after inoculation, adjust the pH to 3.0, an...

Embodiment 3

[0021] Embodiment 3, referring to the accompanying drawings, the high-phosphorus oolitic iron ore with an iron grade of 43.50%, a phosphorus content of 0.85%, and a sulfur content of 0.016% is crushed to a particle size of -3 mm, and magnetized in a box-type resistance furnace Roasting, the roasting temperature is 850°C, the roasting time is 25min, the amount of reducing agent is 5% of the weight of the ore, and then after the ore is ground to -74μm, it is magnetically separated by a weak magnetic separator under the condition of a magnetic field strength of 1500Oe. The ore samples were subjected to microbial leaching tests. The microorganisms used for ore leaching are At.t bacteria, and the microorganisms used for ore leaching are first cultivated in the bioreactor, the inoculum amount is 10% by volume, and the bacterial concentration is 10% during inoculation. 8 ~10 9 cpu / ml, then add 1% sulfur powder according to the liquid mass ratio after inoculation, adjust the pH to 3....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com