Granulation external lubricant adding system and method

A technology for external lubricants and lubricants, which is applied to spray devices, liquid spray devices, etc., can solve the problems of surrounding environment and operator hazards, scattering loss of powdery external lubricants, poor transparency of clear benzene products, etc., to improve production. Stability, improve product appearance, do not affect the effect of transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

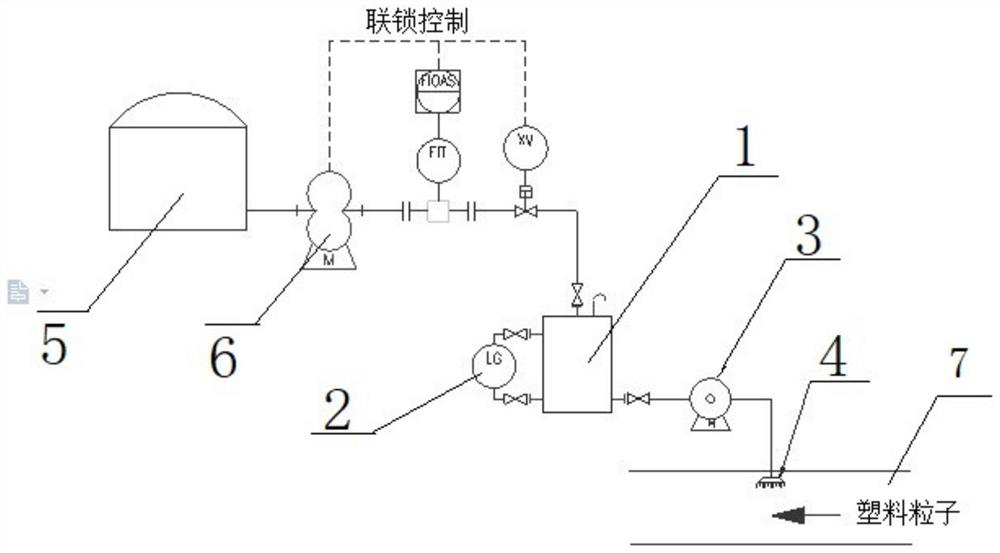

[0023] The external lubricant adding system for granulation of the present invention is illustrated in conjunction with the accompanying drawings.

[0024] Such as figure 1 As shown, the system includes: a liquid storage tank 1, a liquid level gauge 2, a metering pump 3, valves, pipelines, and an electrical control cabinet arranged on the same base, and the liquid storage tank 1 is used to store liquid external lubricant , connected to the mineral oil storage tank 5 through a mineral oil pump 6; the liquid level gauge 2 is used to monitor the liquid level in the liquid storage tank 1, and is arranged on the liquid storage tank 1; the pipeline communicates with the liquid storage tank 1 and pellet air delivery pipe 7; the metering pump 3 is used for quantitatively pumping liquid lubricant, and is arranged on the pipeline; the electrical control cabinet is used for controlling the system, and communicates with the liquid level gauge 2, the Metering pump 3 described above.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com