Engineering plastic processing device and glass fiber content control method

A processing device and technology of engineering plastics, applied in the field of engineering plastics manufacturing, can solve the problems of long detection time, inability to monitor in real time, unstable glass fiber addition, and low accuracy, and achieve simple and practical structure, small error, and high accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

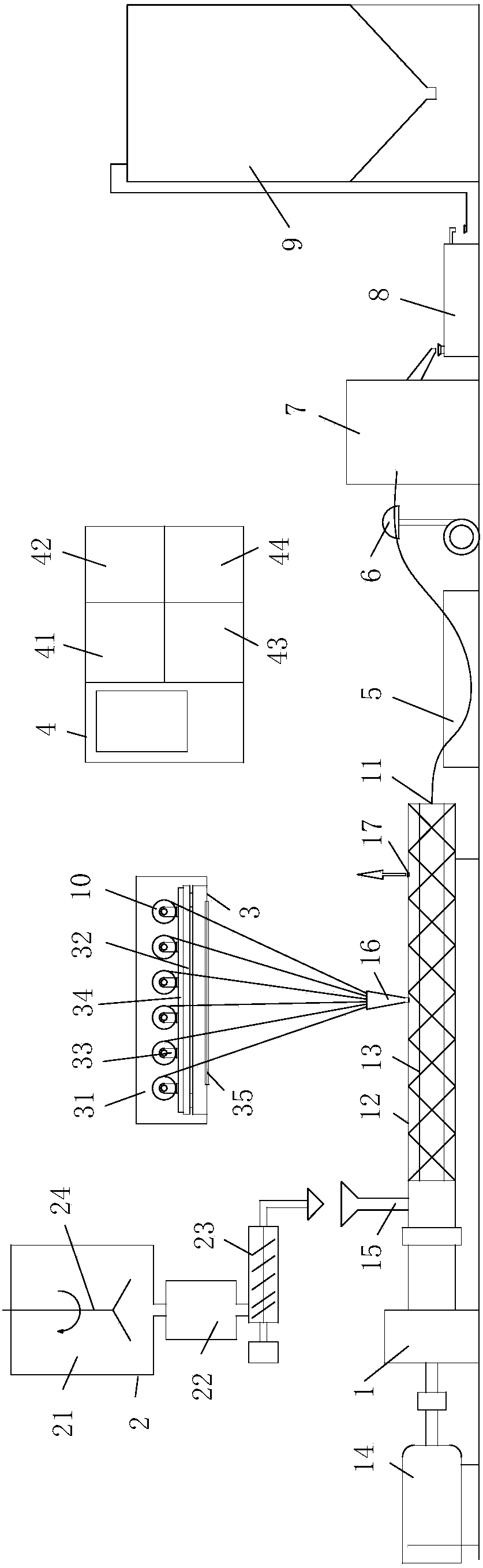

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

[0015] as attached figure 1 Shown: an engineering plastics processing device, including: a twin-screw extruder 1 with a discharge port 11 at the front end, a gravimetric feeding mechanism 2 for the main material of particles and a glass fiber gravimetric feeding mechanism located above the twin-screw extruder 1 Mechanism 3, controller 4; twin-screw extruder 1 includes: cylinder body 12, two screws 13 arranged in cylinder body 12, motor 14 electrically connected with controller 4; It is provided with: a main particle material inlet 15 corresponding to the particle main material weighing feeding mechanism 2, a frustum-shaped glass fiber inlet 16 connected to the cylinder body 12 and corresponding to the glass fiber weighing feeding mechanism 3, and vacuumized Mouth 17.

[0016] The weighing and feeding mechanism 2 of the granular main material comprises: a mixing tank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com