Liquid constant-volume automatic adding system

A technology of automatic adding and liquid medicine, applied in control/adjustment system, liquid level control, non-electric variable control and other directions, can solve the problems of increasing labor cost, difficult to be found, deviation of liquid pump flow, etc., to facilitate correction and maintenance. , The effect of saving production costs and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

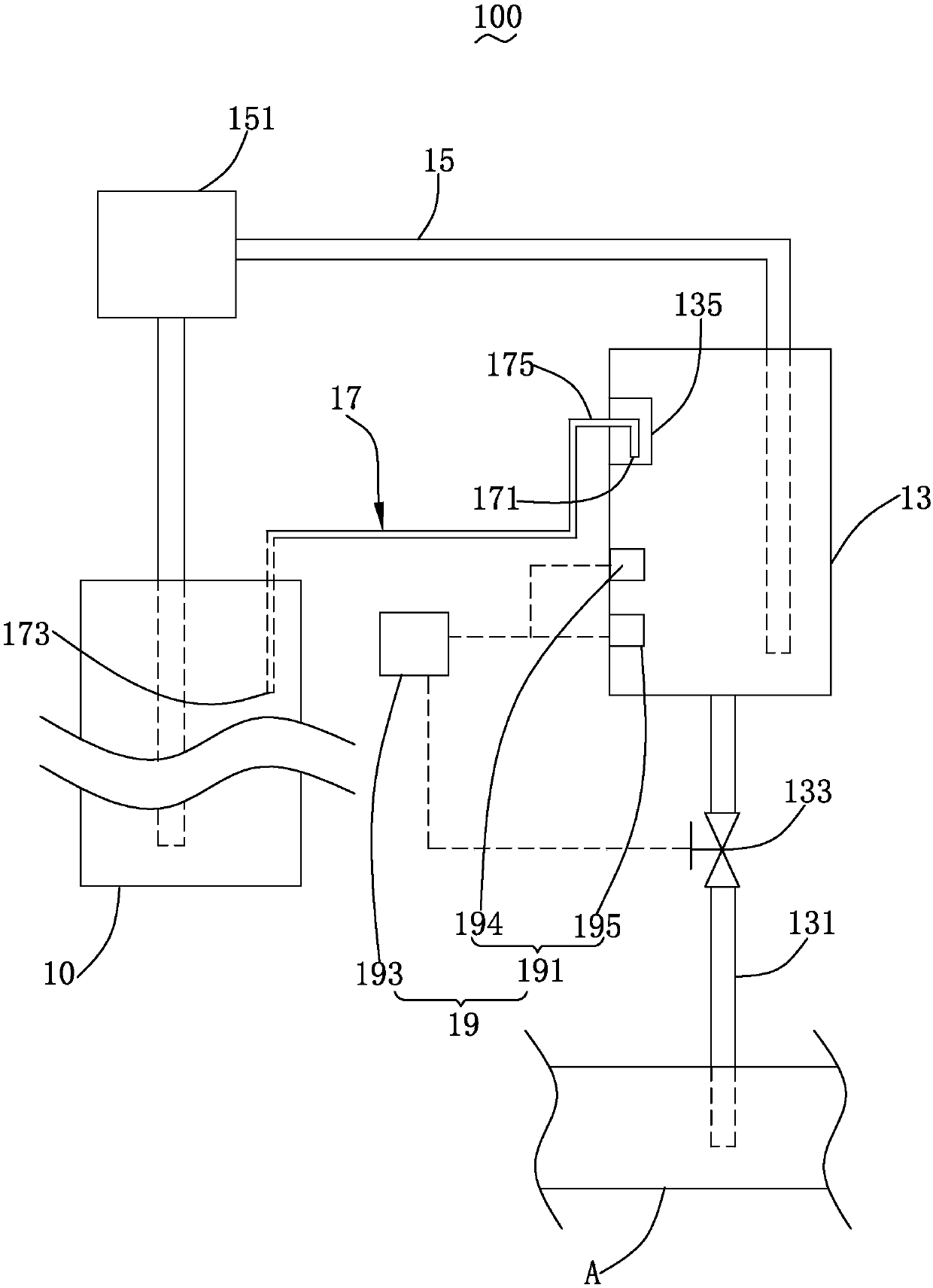

[0039] see figure 1, is a structural schematic diagram of Embodiment 1 of the automatic volume-adding system for medicinal liquid of the present invention. The medicinal liquid constant volume automatic adding system 100 is used to automatically add a constant volume of medicinal liquid to the medicinal tank A, which includes a medicinal liquid source 100, a container 13, a liquid inlet pipe 15, a siphon pipe 17 and a control device 19. The liquid medicine source 10 is used to provide the liquid medicine, the bottom of the container 13 is provided with a liquid outlet pipe 131, the liquid outlet pipe 131 is provided with a first control valve 133, and the liquid inlet pipe 15 is used to supply the liquid medicine The liquid medicine in the source 10 is transported into the container 13, the liquid pump 151 is provided on the liquid inlet pipe 15, one end of the siphon pipe 17 is arranged in the container 13, and the other end is arranged in the container 13 In addition, the c...

Embodiment 2

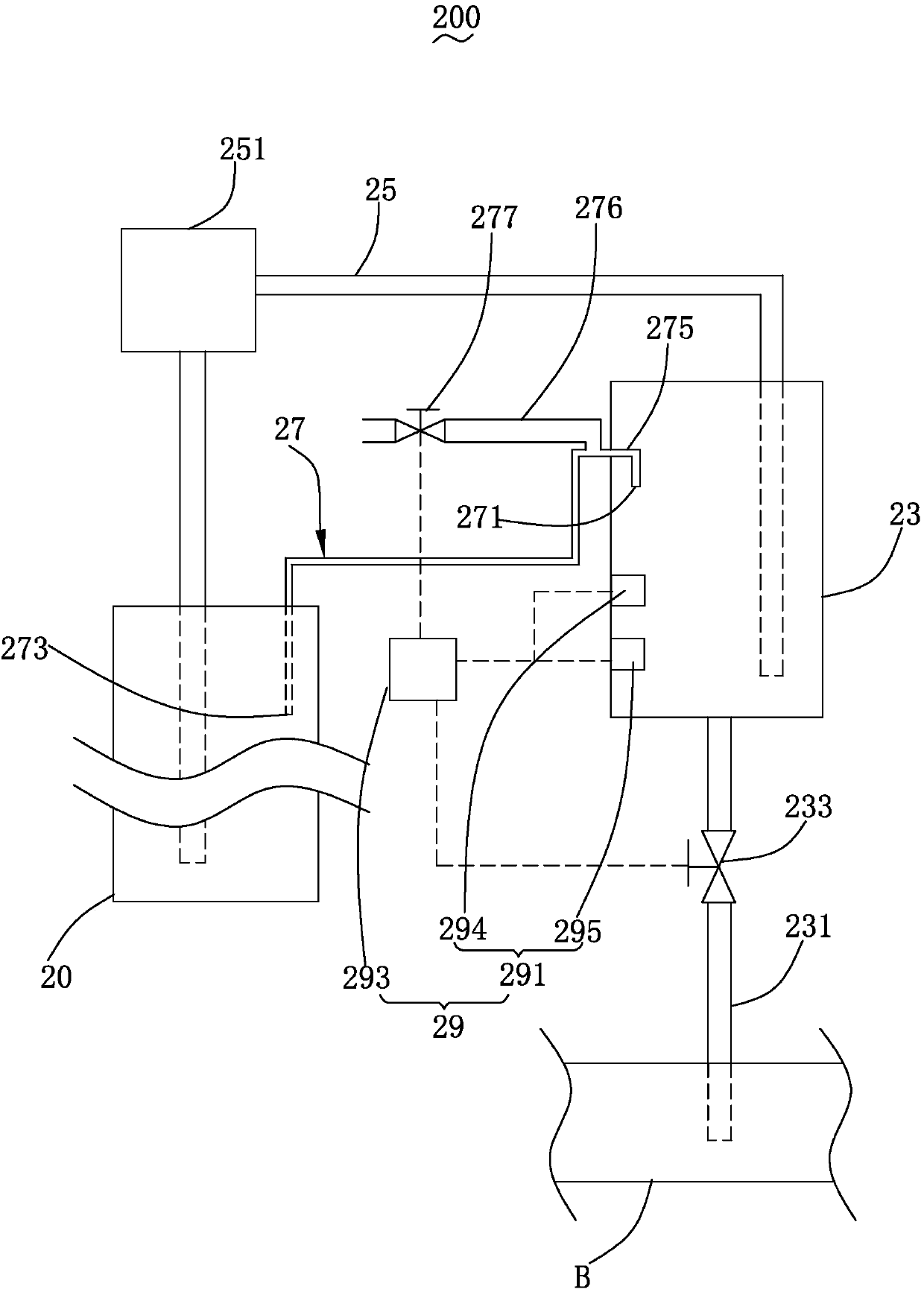

[0056] see figure 2 , is a structural schematic diagram of Embodiment 2 of the automatic adding system for constant volume of liquid medicine of the present invention. The medicinal solution constant volume automatic adding system 200 is used to automatically add a constant volume of medicinal solution to the medicine tank B, which includes a medicinal solution source 20, a container 23, a liquid inlet pipeline 25, a siphon pipeline 27 and a control device 29. The liquid medicine source 20 is used to provide the liquid medicine, the bottom of the container 23 is provided with a liquid outlet pipe 231, the liquid outlet pipe 231 is provided with a first control valve 233, and the liquid inlet pipe 25 is used to supply the liquid medicine The liquid medicine in the source 20 is transported into the container 23, the liquid inlet pipe 25 is provided with a liquid pump 251, one end of the siphon pipe 27 is arranged in the container 23, and the other end is arranged in the contain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com