Degradable compressive discoloring plastic color masterbatch and preparation method thereof

A pressure discoloration and color masterbatch technology, applied in the field of plastic coloring, can solve the problems of non-replanting, land pollution, increased damage rate of plastic products and use costs, etc., to protect health and environment, protect cleanliness, and maintain chemical stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A degradable pressure-changing plastic color masterbatch, which is composed of the following substances in mass fractions: 10% titanium dioxide, 10% starch, 0.5% titanate coupling agent, 0.5% stearic acid, 75% polylactic acid, di Vinyl anthracene PAIE compound 4%.

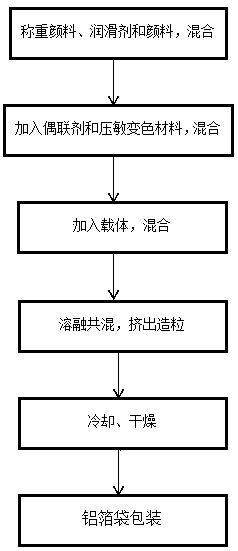

[0028] A method for degradable pressure-changing plastic color masterbatch, comprising the following steps:

[0029] Step A: put titanium dioxide, stearic acid and starch into a high-speed mixer, and stir at a high speed for 5 minutes at 95°C;

[0030] Step B: Add titanate coupling agent and divinyl anthracene PAIE compound into the high-speed mixer, and stir at high speed for 5 minutes;

[0031] Step C: Finally, add polylactic acid into the high-speed mixer, stir at high speed for 3 minutes, and obtain the mixture after discharging;

[0032] Step D: Melt and blend the mixture obtained in Step C through a twin-screw extruder, extrude and granulate, cool, dry, and pack in an aluminum foil bag to obtain a de...

Embodiment 2

[0034] A degradable pressure-changing plastic color masterbatch, which is composed of the following substances in mass fractions: 15% of permanent red, 20% of silica modified calcium carbonate, 0.1% of silane coupling agent, and 0.9% of ethylene bisstearamide %, butylene terephthalate 59%, tetraphenylethylene PAIE compounds 5%.

[0035] A method for preparing degradable pressure-changing plastic color masterbatch, comprising the following steps:

[0036] Step A: Put permanent red, ethylene bisstearamide and silica-modified calcium carbonate into a high-speed mixer, and stir at a high speed for 7 minutes at 100°C;

[0037] Step B: Add silane coupling agent and tetraphenylethylene PAIE compound into the high-speed mixer, and stir at high speed for 7 minutes;

[0038] Step C: Finally, add butylene terephthalate into the high-speed mixer, stir at high speed for 4 minutes, and obtain a mixture after discharging;

[0039] Step D: Melt and blend the mixture obtained in Step C throu...

Embodiment 3

[0041] A degradable pressure-changing plastic color masterbatch, which is composed of the following mass fractions: carbon black 30%, clay 14%, borate coupling agent 1%, fatty acid amide 5%, polylactic acid 40%, silole 10% of PAIE-like compounds, wherein the carrier is polylactic acid or butylene terephthalate.

[0042] A method for preparing degradable pressure-changing plastic color masterbatch, comprising the following steps:

[0043] Step A: Put carbon black, fatty acid amide and clay into a high-speed mixer, and stir at a high speed for 10 minutes at 105°C;

[0044] Step B: Add borate coupling agent and silole PAIE compound into the high-speed mixer, and stir at high speed for 10 minutes;

[0045] Step C: Finally, add polylactic acid into the high-speed mixer, stir at high speed for 5 minutes, and obtain the mixture after discharging;

[0046] Step D: Melt and blend the mixture obtained in step C through a twin-screw extruder, extrude and granulate, cool, dry, and pack ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com