Method for manufacturing blast furnace stemming

A technology for popping mud and blast furnace, applied in the field of blast furnace mud preparation, can solve the problems of raw material temperature, equipment temperature being difficult to control, inability to strictly implement technical formula requirements, high labor intensity of operators, etc., achieving moderate mud fighting pressure and labor intensity. The effect of lowering and good construction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

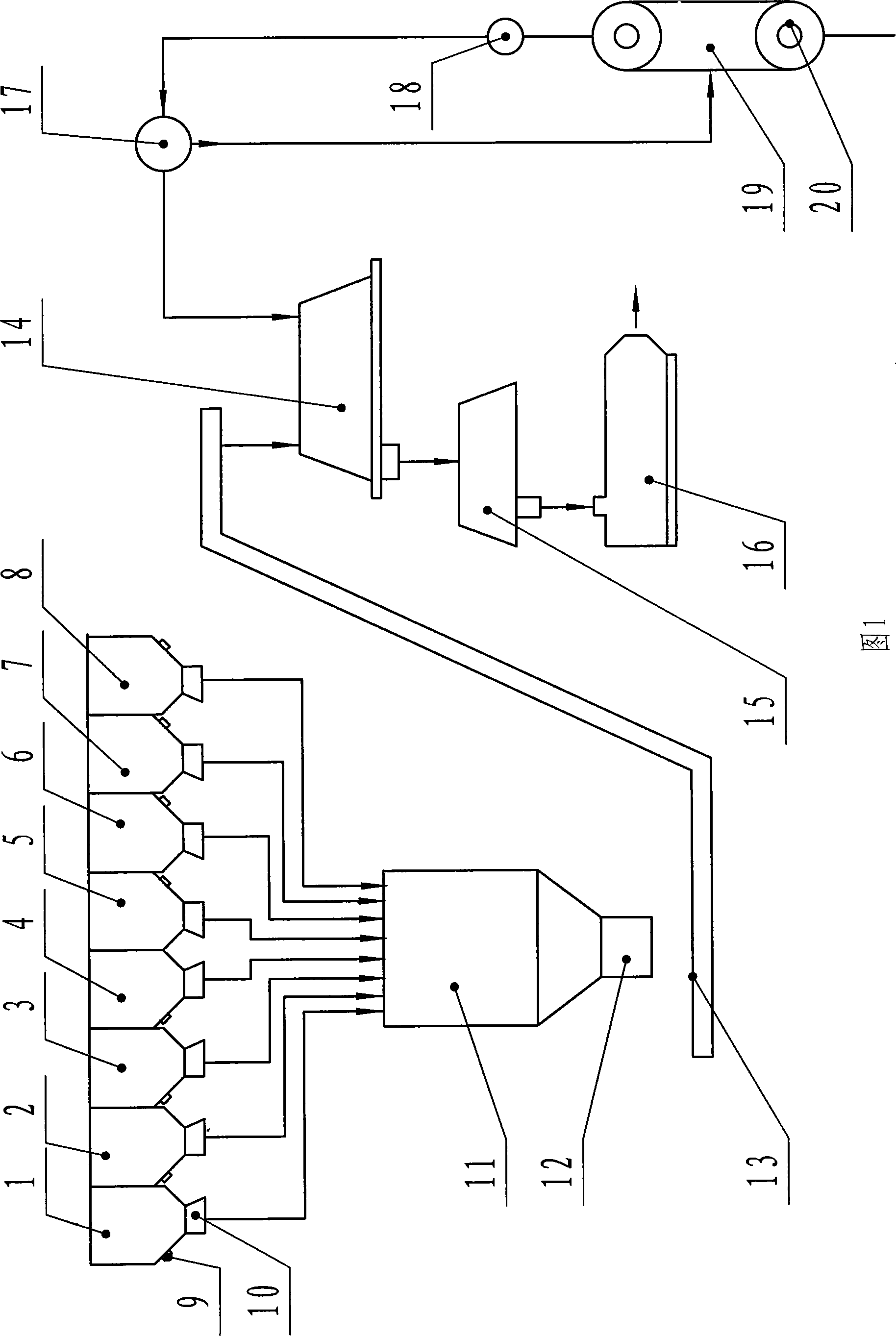

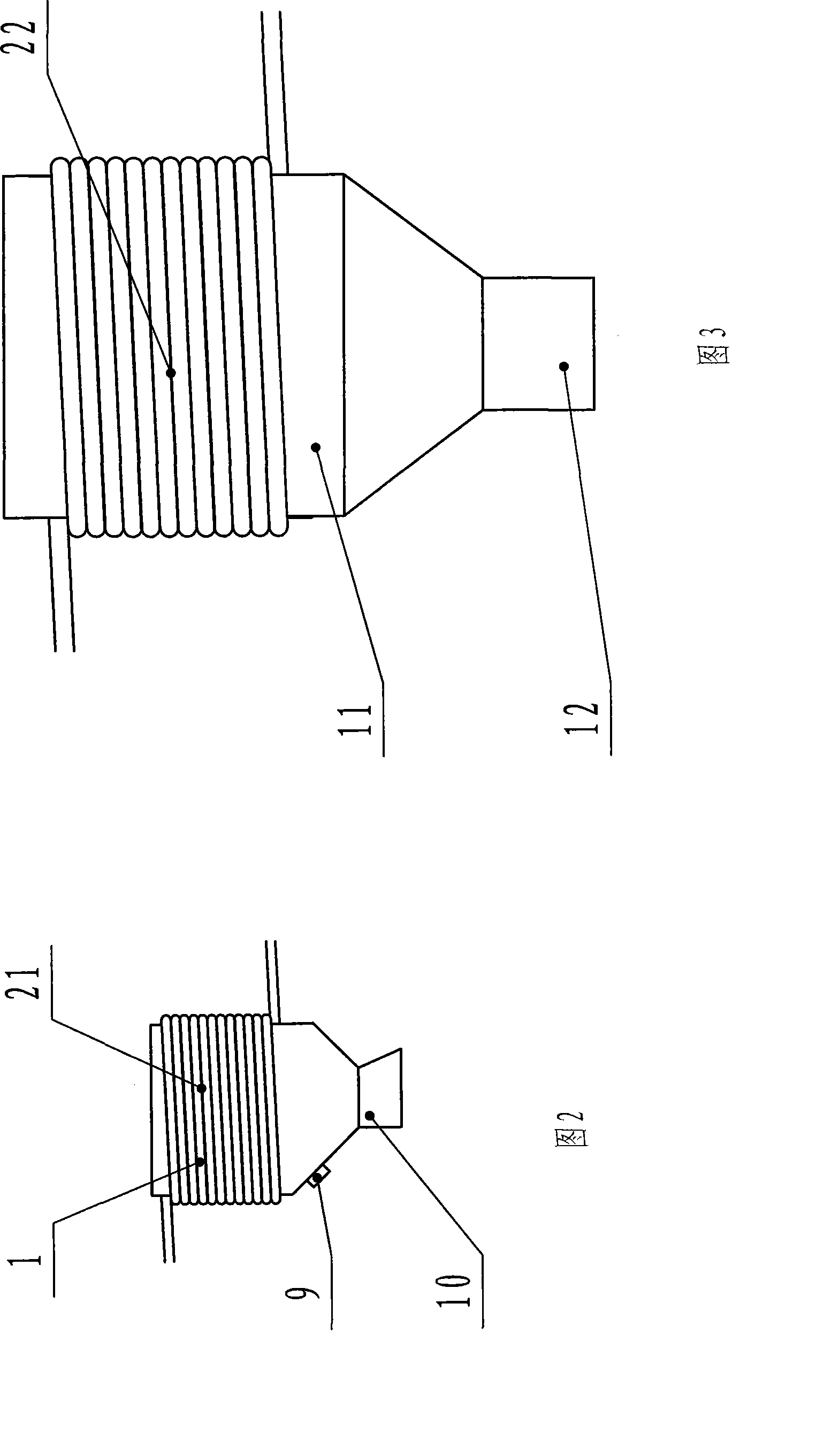

[0055] The preparation process of this embodiment can be found in figure 1 , the bulk raw material is heated to 40°C from the storage tank such as the fused corundum by the heating tube 21 outside the fused corundum storage tank 1, see figure 2 , from fused corundum storage tank 1, silicon carbide storage tank 2, clay storage tank 3, coke powder storage tank 4, sericite storage tank 5 and additive storage tank 6, the electric feeder 10 respectively feeds the bulk raw material fused corundum , silicon carbide, clay, coke powder, sericite and additives are added to the weighing funnel device 11, and the weighing funnel device 11 is heated to 70°C by the heating tube 22 outside to ensure that the raw material in the weighing funnel device 11 is 30°C. ℃-40℃, the heating medium in the heating tube in this embodiment is WRY type high temperature heat transfer oil see image 3 , the (reconstitution ratio) of bulk raw materials is:

Embodiment 2

[0064] The preparation steps of this example are the same as those of Example 1, except that the weight ratio of raw materials and the preparation temperature are different from Example 1. The weight proportion of the bulk raw material of the present embodiment is:

[0065] Fused corundum 40 Silicon carbide 15 Clay 5 Coke powder 5

[0066] Sericite 5 Additives 5.

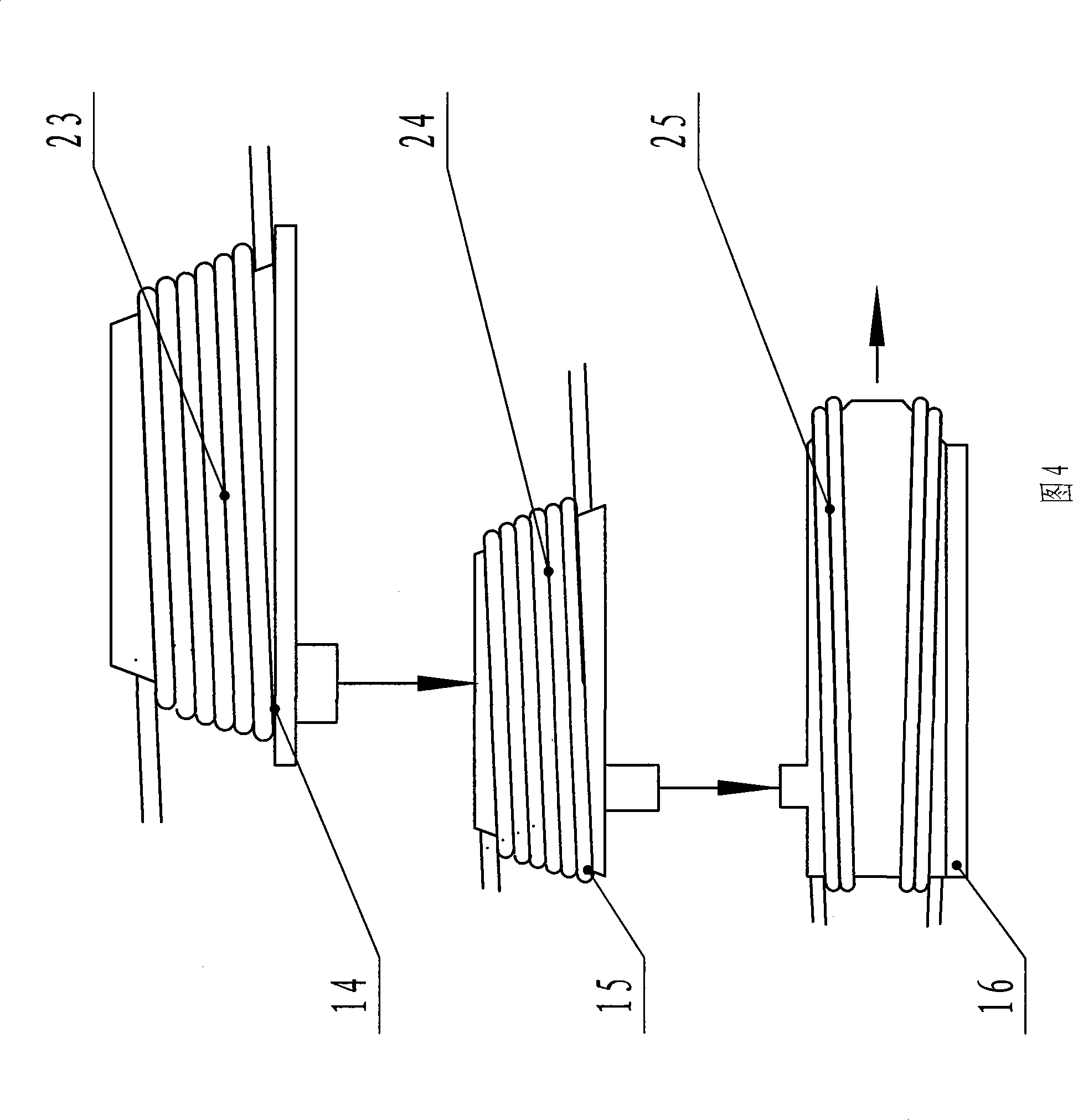

[0067] The temperature of the bulk raw material in the storage tank is 20°C, heated to 20°C-30°C by the heating tube 22 on the outside of the weighing funnel device 11, dry mixed for 10 minutes, and added a binder with a weight ratio of 15. The mud mill 14 rolled for 40 minutes, and the molding machine 16 was molded at 50°C. The composition (weight ratio) of the blast furnace clay of making is:

[0068] Fused corundum 40 Silicon carbide 15 Clay 5 Coke powder 5

[0069] Sericite 5 Additive 5 Binder 15.

Embodiment 3

[0071] The preparation steps of this embodiment are the same as those of Example 1, and the difference from Example 1 is that the weight ratio of raw materials is different. The composition (weight ratio) of the blast furnace clay made in this embodiment is:

[0072] Fused corundum 50 Silicon carbide 17.5 Clay 7.5 Coke powder 6.5

[0073] Sericite 7.5 Additive 12.5 Binder 20.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com