Patents

Literature

40results about How to "Stable physical and chemical indicators" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Biological orgamic fertilizer and prepn thereof

ActiveCN1834066AImprove stress resistanceImprove disease resistanceBio-organic fraction processingBacteriaMicroorganismBiotechnology

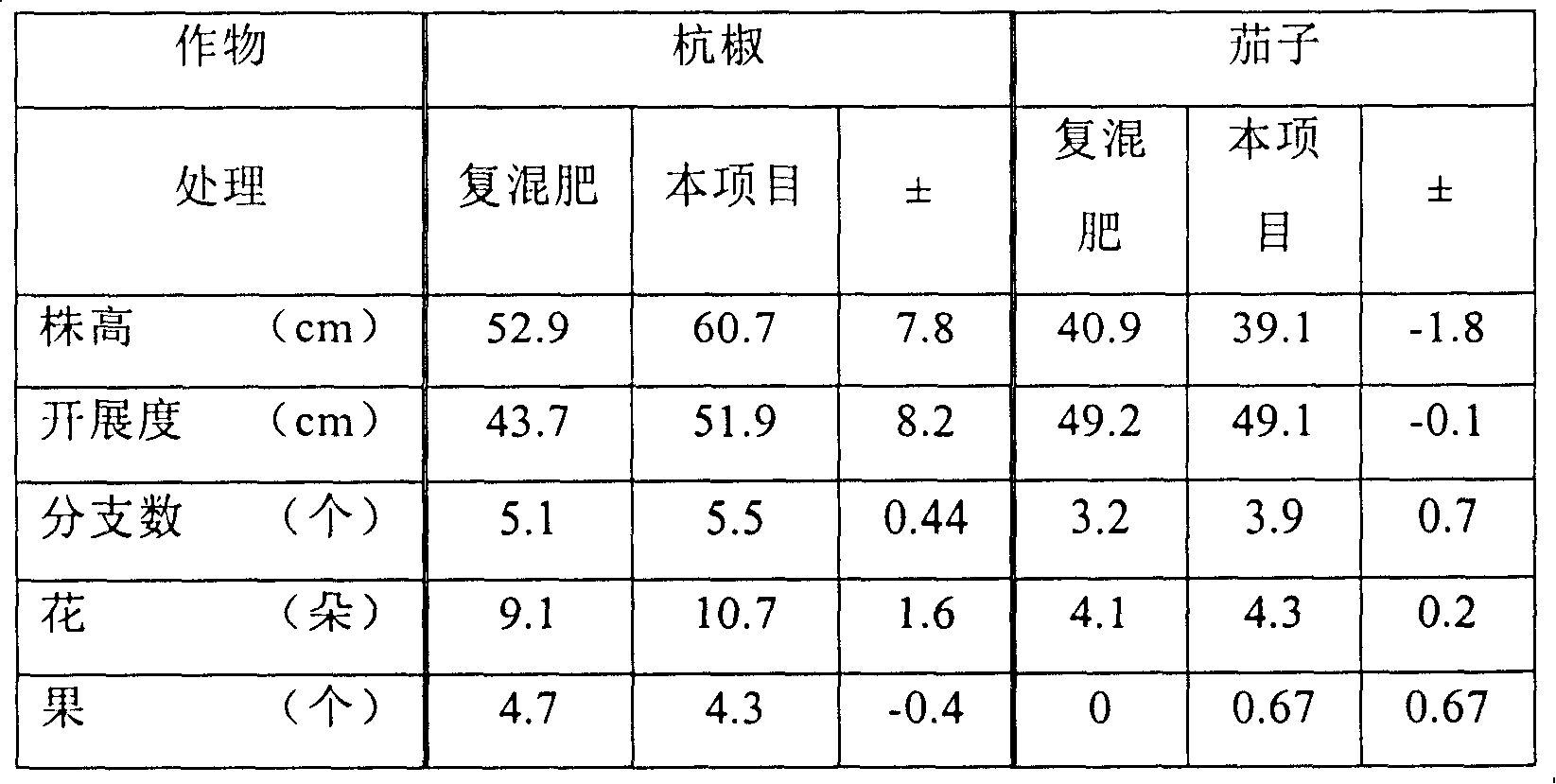

This invention relates to a method to prepare a kind of bioorganic fertilizer and its application. The preparation method includes following steps: a) proliferation and cultivation of microorganism species; b) cultivation of microorganism species against stalk antibody; c) adsorption onto a carrier and drying into organic decomposers; d) preprocessing of organic waste; e) inoculation complex fermentation and f) continuous high-temperature fermentation and nontoxification. This invention has the advantages of advanced technique, low production cost, stable product quality and long fertility persistence and can be widely applied in the production of corns, vegetables, fruits and all kinds of economic crops. Besides, it is a green method makes considerable economic, social and environmental benefits.

Owner:上海联业农业科技有限公司

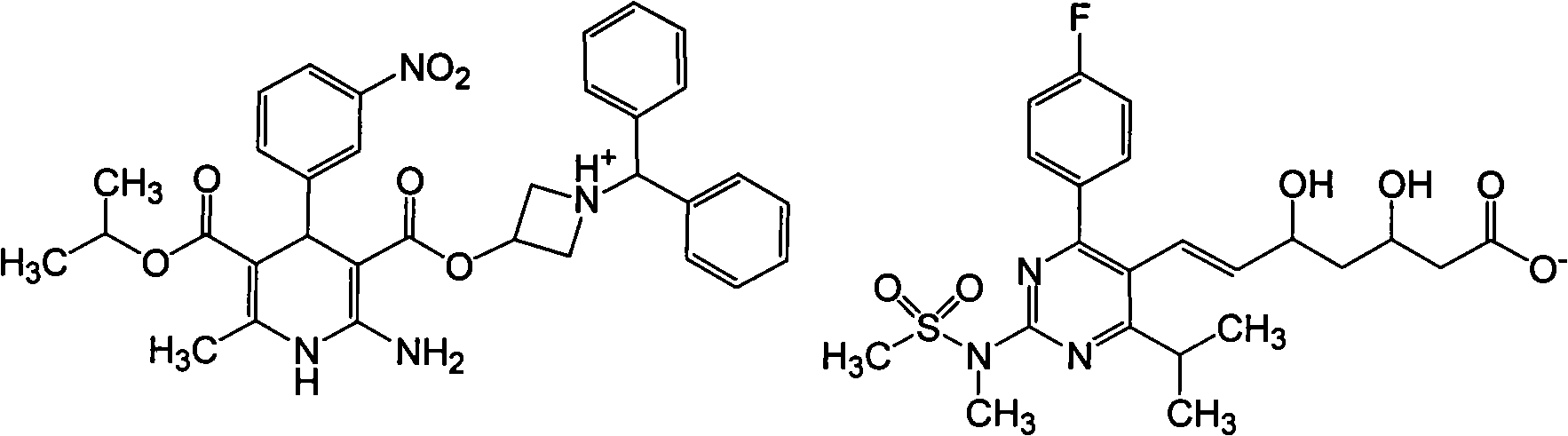

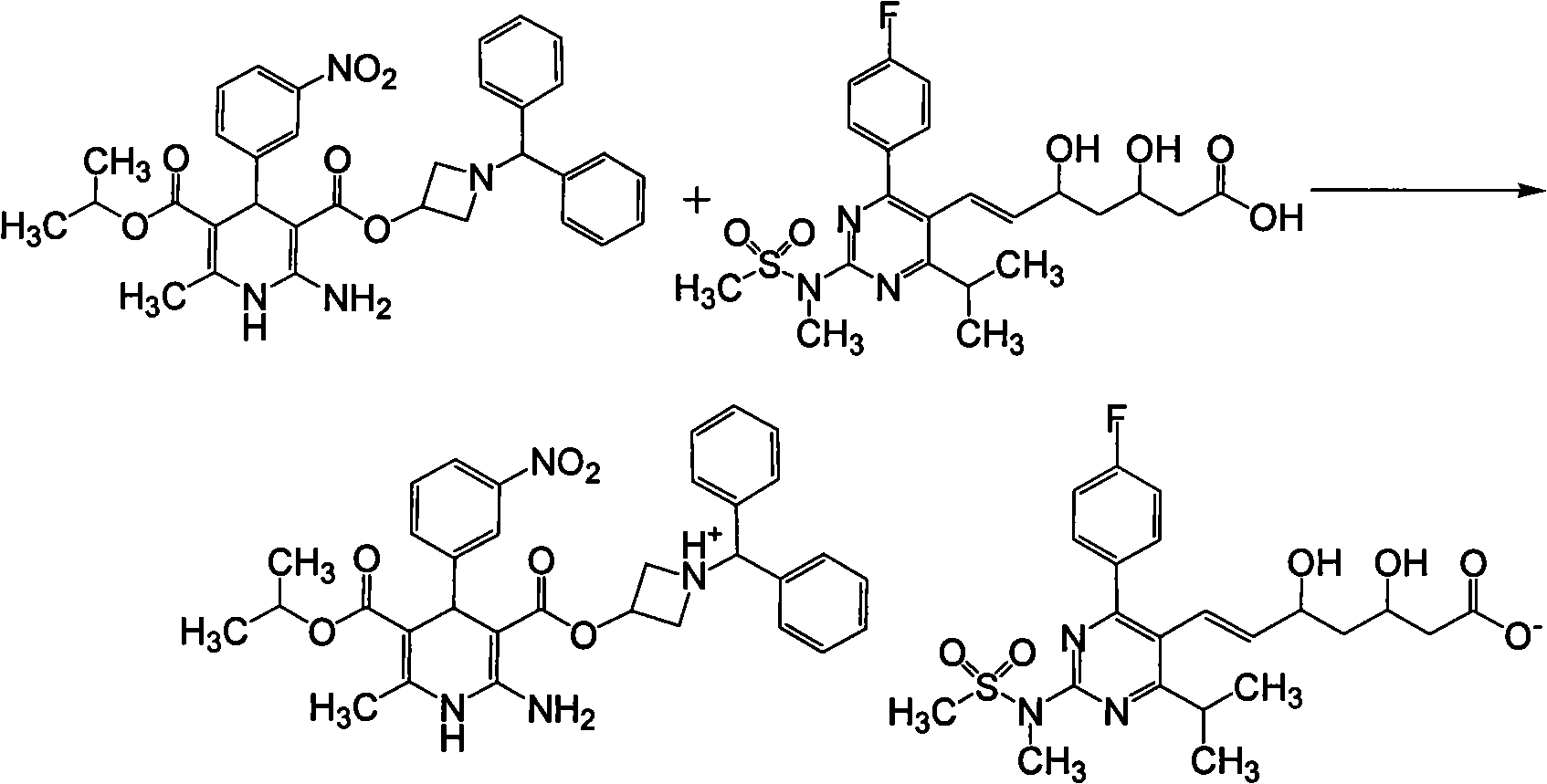

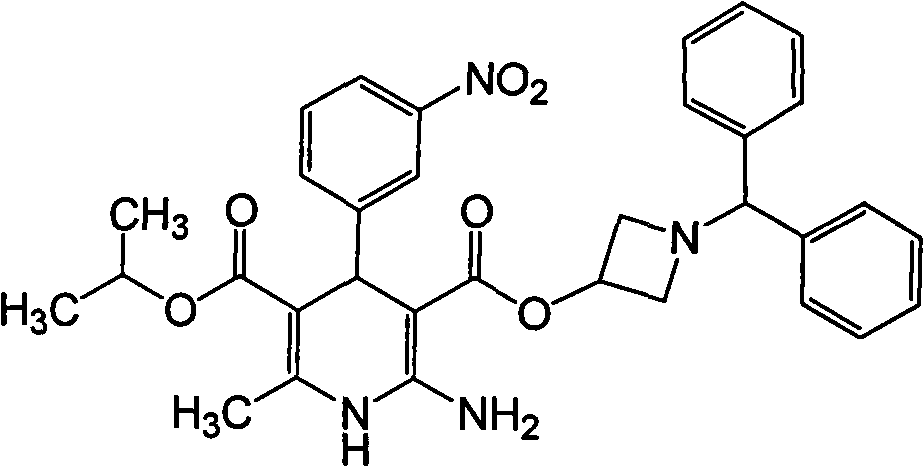

Rosuvastatin azelnidipine composition

InactiveCN101336921ALower blood pressureLower blood lipid levelsOrganic active ingredientsMetabolism disorderOrganic acidOrganic base

A pharmaceutical composition is an organic salt formed by an organic acid rosuvastatin and an organic base azelnidipine with a molar ratio of 1:1. The pharmaceutical composition can be made into any dosage forms together with a pharmaceutically-acceptable carrier for reducing blood pressure and blood lipid, reducing myocardial infarction and treating cerebral apoplexy. The inventive pharmaceutical composition has the advantages of stable physiochemical indexes, controllable product quality, and convenient administration.

Owner:QINGDAO HUANGHAI PHARM CO LTD

Special continuous casting crystallizer casting powder for carbon steel in ESP

ActiveCN107931552AMeet the requirements of slag consumptionMeet the process requirementsSlagCarbon steel

The invention belongs to the technical field of steel making, and particularly relates to special continuous casting crystallizer casting powder for carbon steel in ESP. The special continuous castingcrystallizer casting powder for carbon steel in ESP comprises the following chemical components in percentages by mass: 29%-33% of CaO, 23%-27% of SiO2, 6.5%-8% of MgO, 3.5%-6% of of Al2O3, 6%-8% ofNa2O, 7.5%-9.5% of F<->, 1%-3% of MnO2, 0.4%-0.7% of Li2O and 2.5%-4.0% of C. The slagging speed is high, uniform slagging is implemented, the thickness of a slag film is suitable, consumption is moderate, and quality defects on the surface of a casting blank can be prevented.

Owner:XIXIA LONGCHENG METALLURGICAL MATERIALS CO LTD

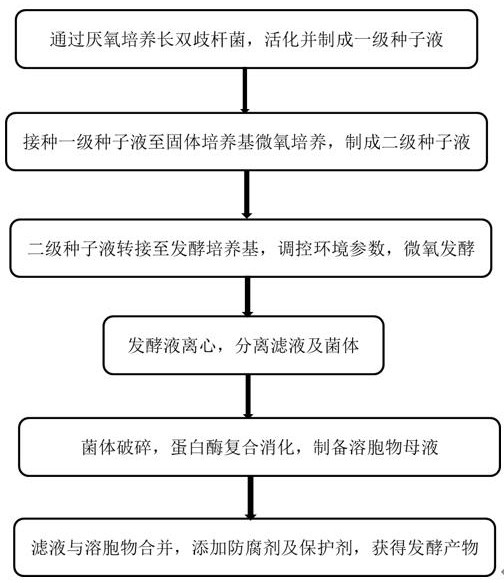

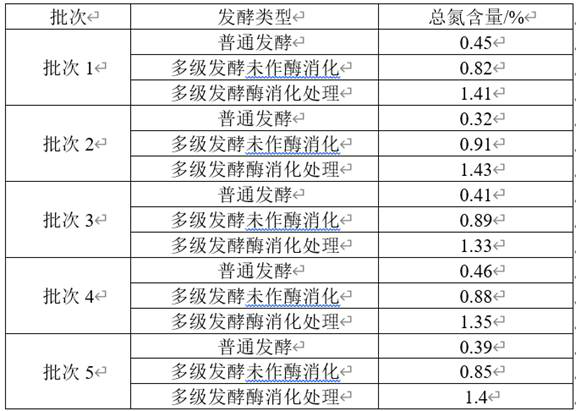

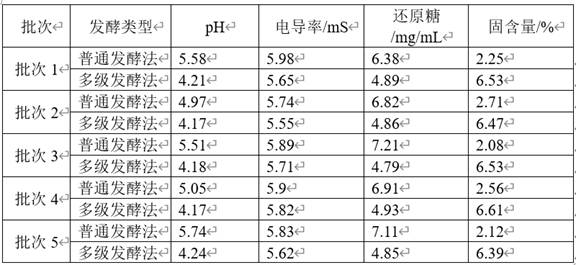

Bifid yeast fermentation composition and preparation method thereof

InactiveCN112675081AReduce lossesGuaranteed concentrationCosmetic preparationsBacteriaBiotechnologyCulture mediums

The invention relates to a bifid yeast fermentation composition and a preparation method thereof. The fermentation composition is formed by mixing bifid yeast lysis substance mother liquor and filtrate according to a certain ratio. The preparation method comprises the following steps of: S1: carrying out anaerobic culture and activation to prepare a first-level fermentation seed solution; S2: inoculating the first-level fermentation seed solution into a micro-aerobic fermentation solid culture medium to obtain a second-level fermentation seed solution; S3: transferring the second-level fermentation seed solution into the fermentation culture medium to carry out micro-aerobic fermentation; S4: through fermentation broth centrifugation, separating bifid yeast filtrate from bifidobacterium bodies; S5: after the bifidobacterium bodies are resuspended and broken, obtaining the bifid yeast lysis substance mother liquor; and S6: mixing the bifid yeast filtrate with the lysis substance mother liquor to obtain a bifid yeast fermentation product. Since bifidobacterium longum is used for carrying out multilevel anaerobic / micro-aerobic fermentation, the problem of a microorganism pollution influence is restricted, and safety is further improved; indexes, including an oxygen content, are controlled in a step-by-step fermentation process, and each physicochemical index of a final product is stable; and through a compound protease digestion technology, the content of polypeptides under same-scale bifidobacterium fermentation is effectively improved.

Owner:天津强微特生物科技有限公司

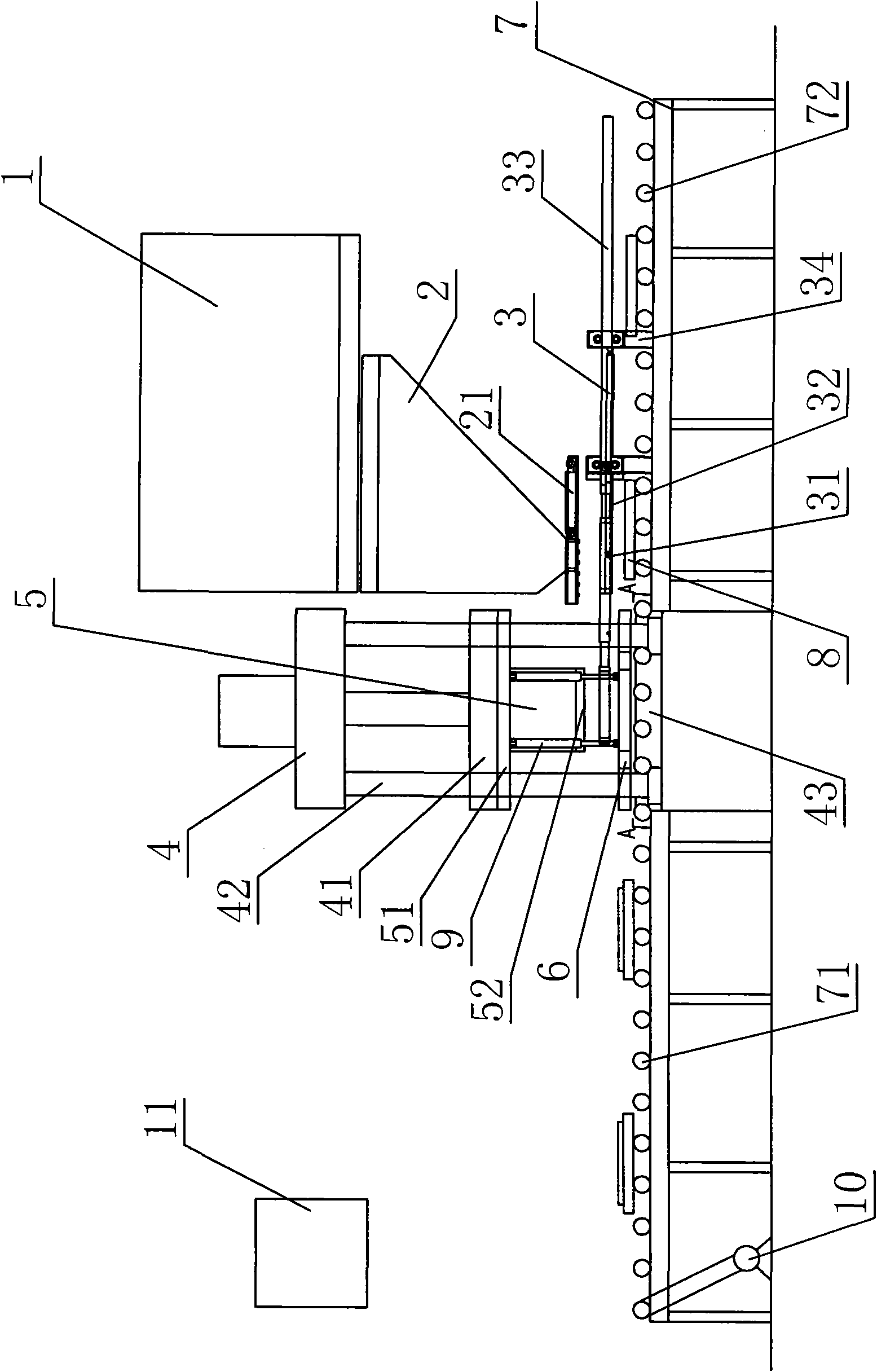

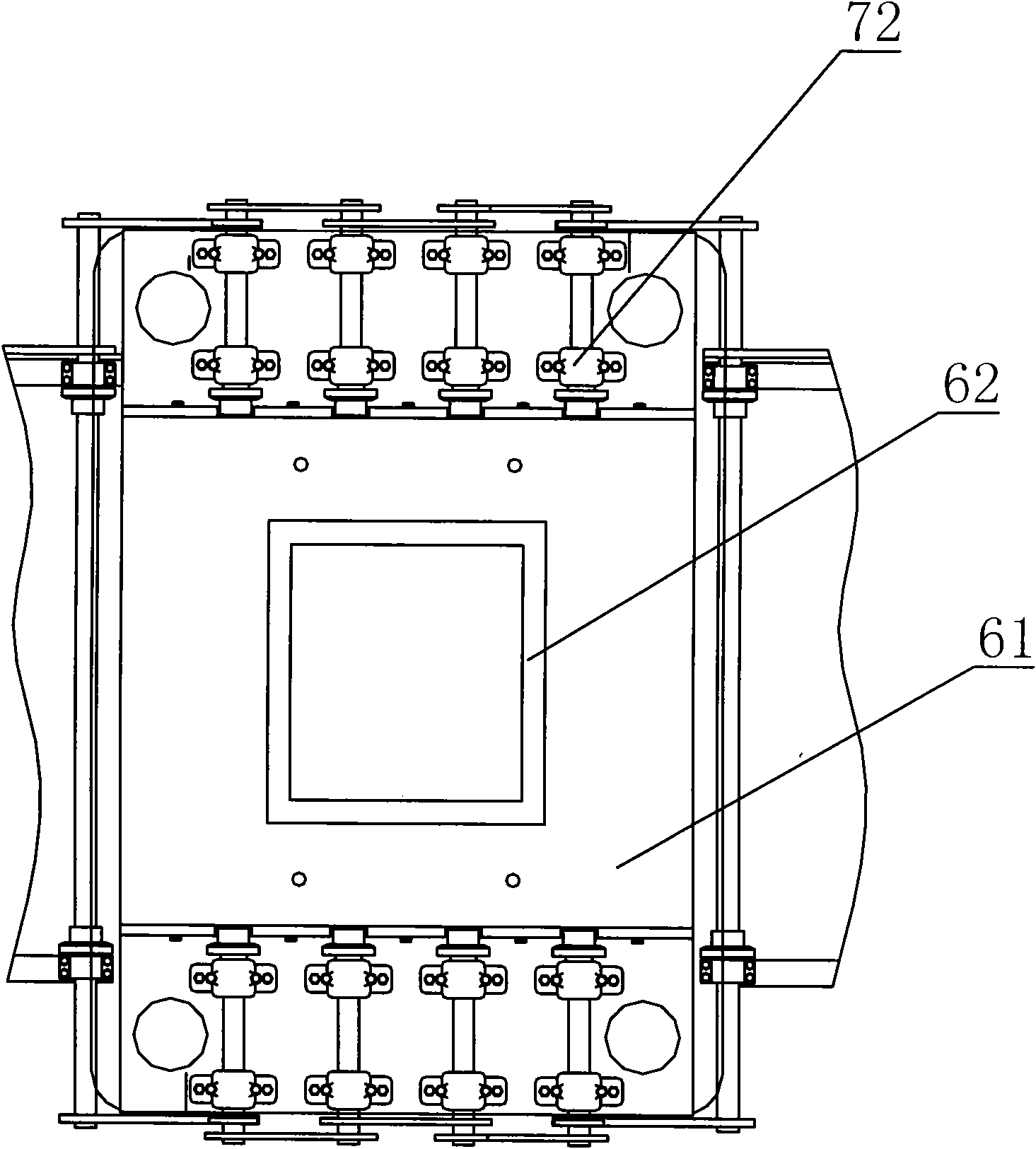

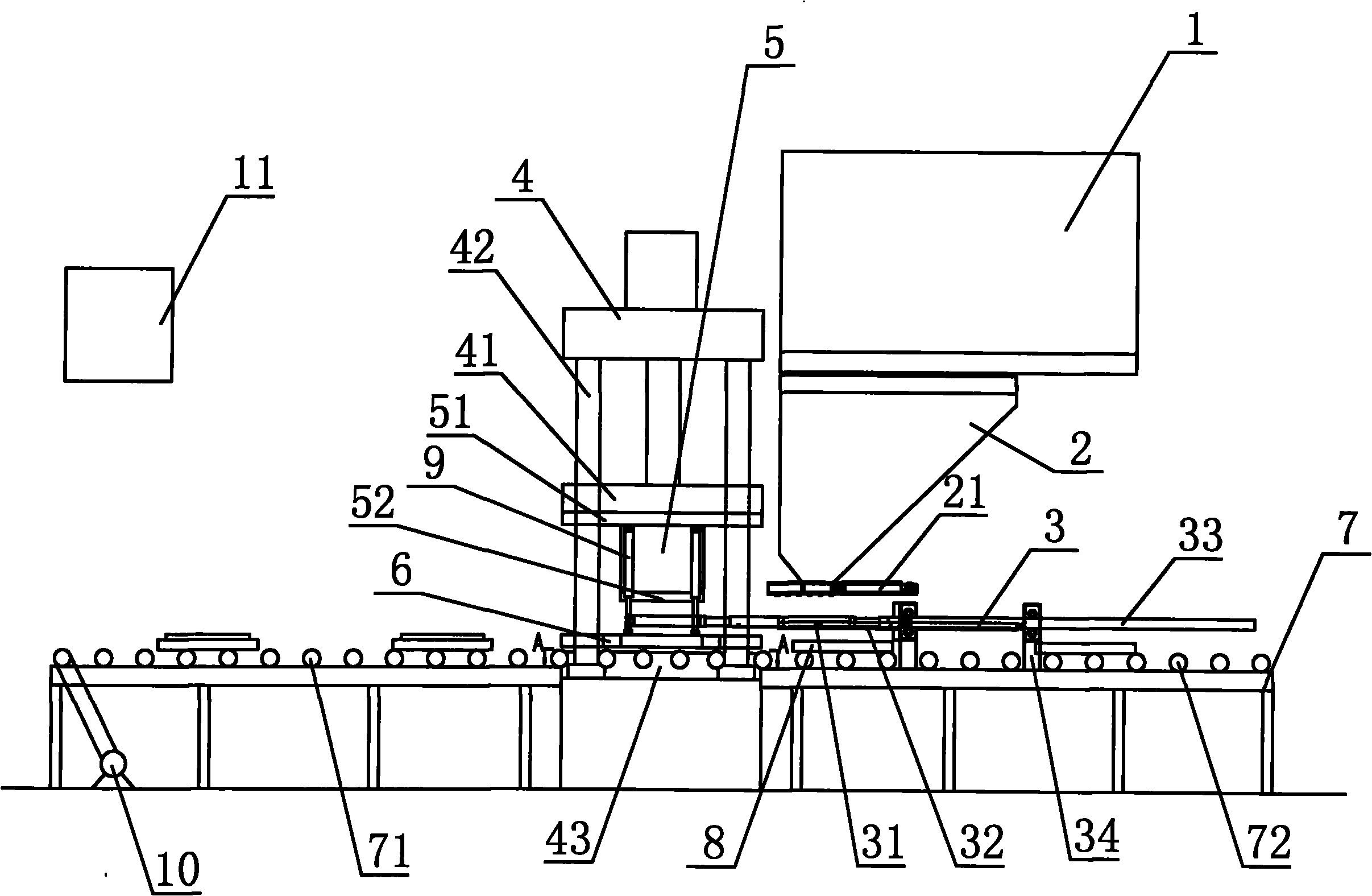

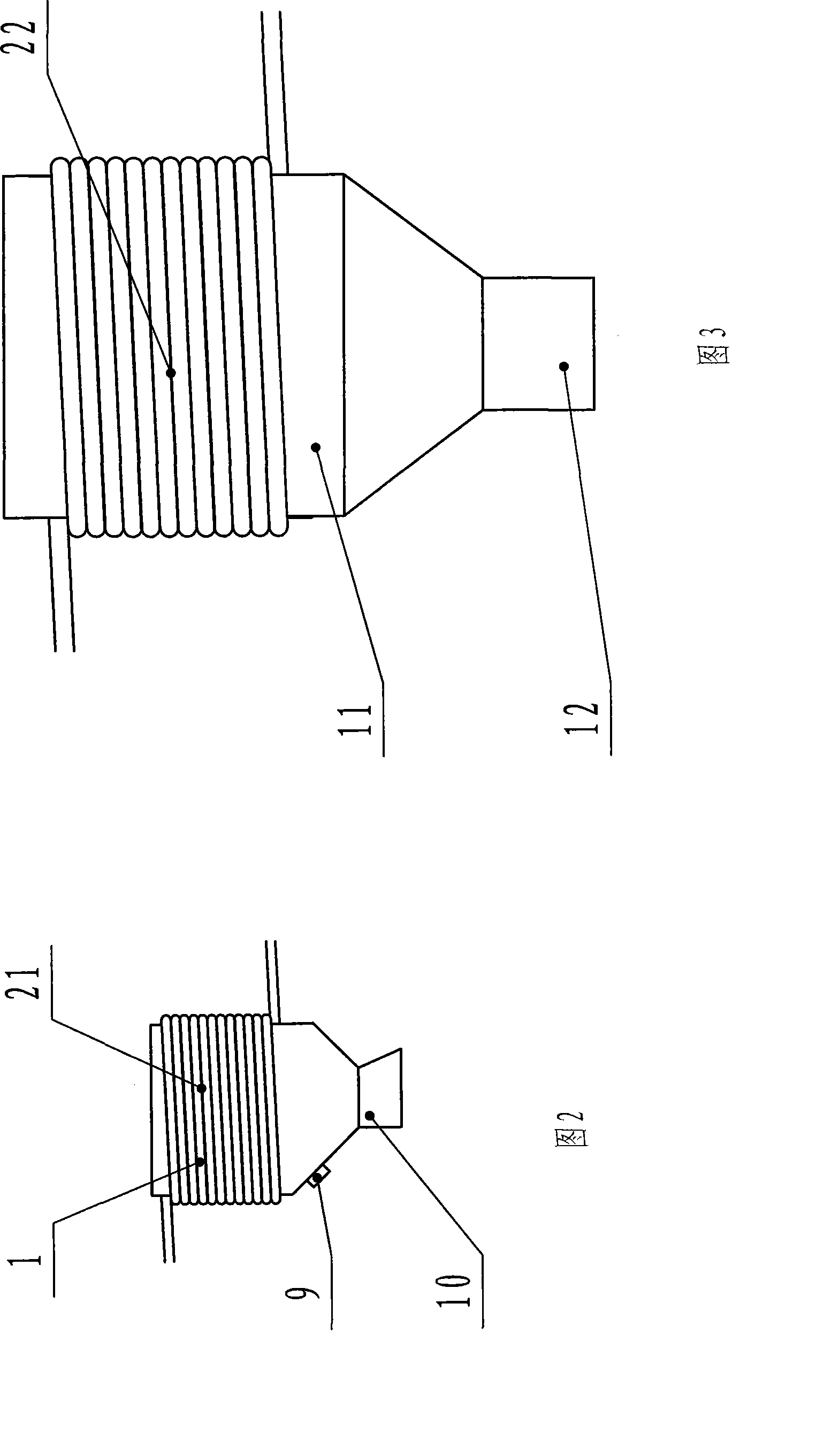

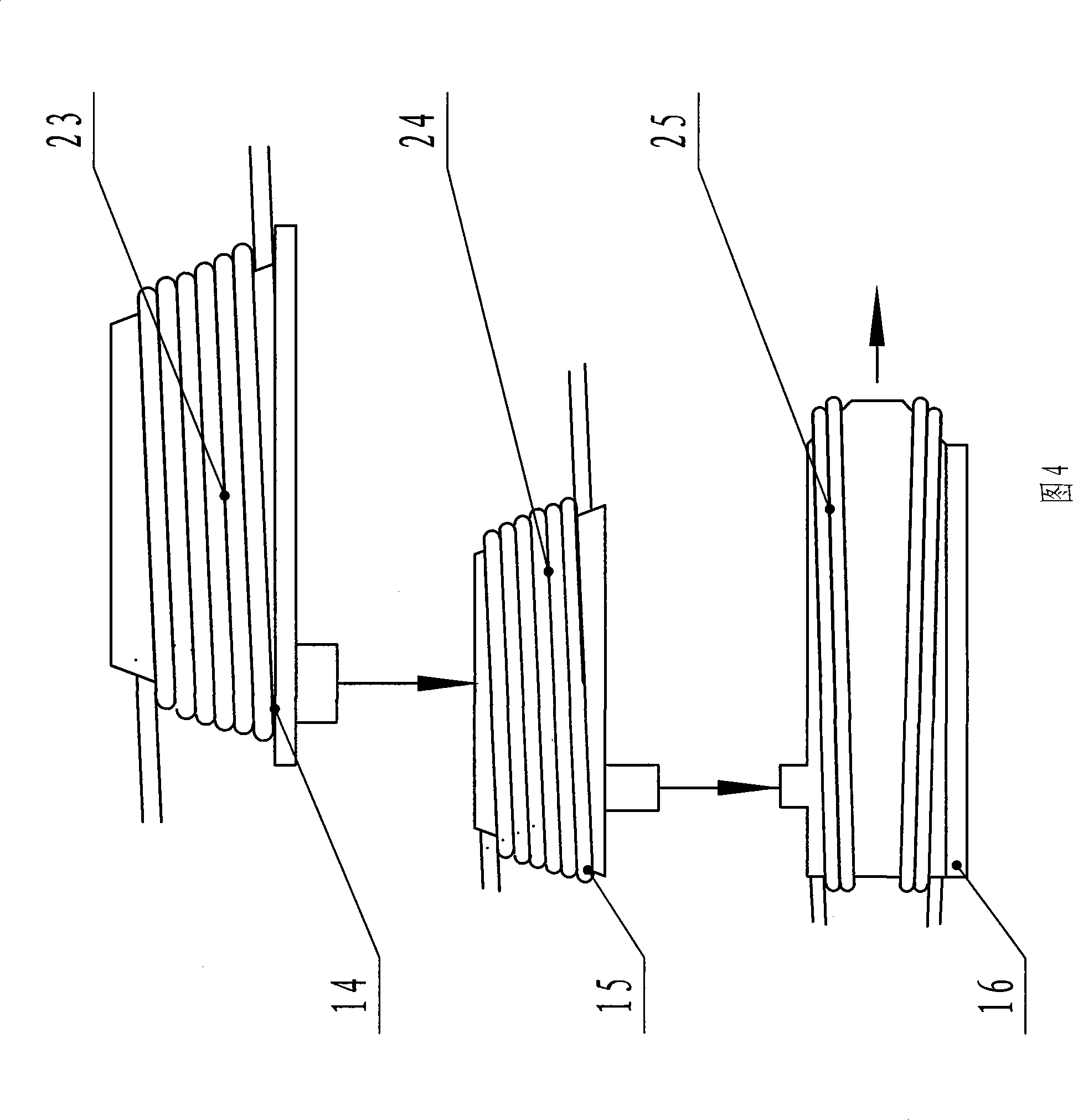

Full-automatic concrete board die casting machine

InactiveCN102085690AWith strengthStable mechanical propertiesCeramic shaping apparatusHydraulic cylinderAutomatic control

The invention discloses a full-automatic concrete board die casting machine, comprising a stirring machine, a hopper, a burdening mechanism, a press, a male die, a female die, a conveying mechanism, a tray, a hydraulic cylinder, a driving device and a hydraulic electrical system. The full-automatic concrete board die casting machine automatically controls material distributing and burdening, the burdening accuracy of the stirred size can be more than 1%, and the physical and chemical indexes of the product are ensured to be stable and consistent; quantitative charging and compression moulding are automatically controlled, the thickness of the product is uniform, and the mechanical properties of the product are stable; the semi-finished product after compression moulding is finished has a certain strength and can move and rotate on the tray, thus the maintenance stage can be directly carried out, and the requirement on a production site is greatly lowered; and full-automatic operation is adopted, the process is advanced, the machine is convenient to use, and the stability is good.

Owner:无锡市康特建筑机械有限公司 +1

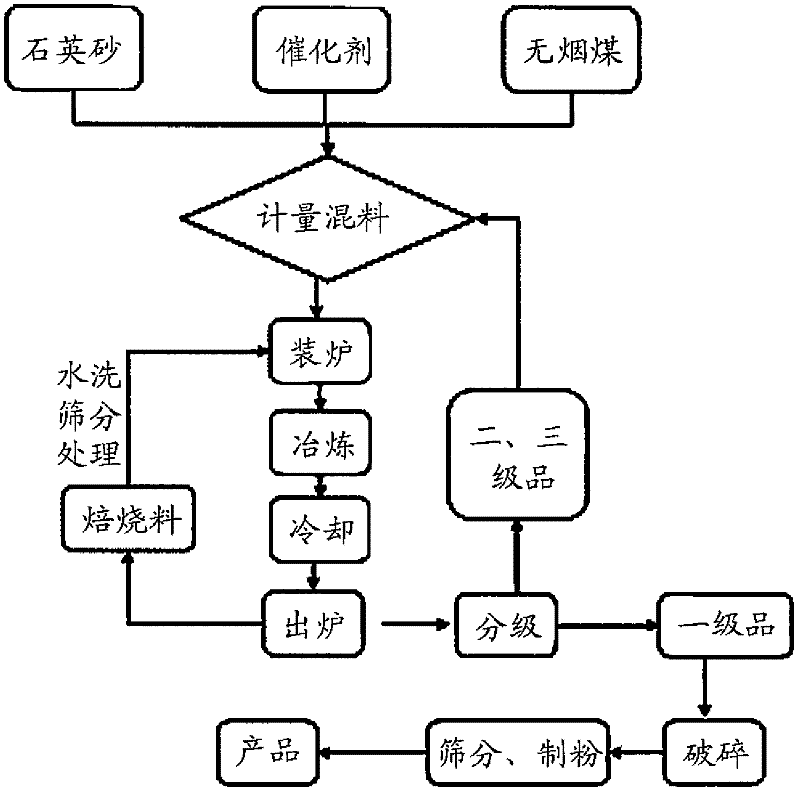

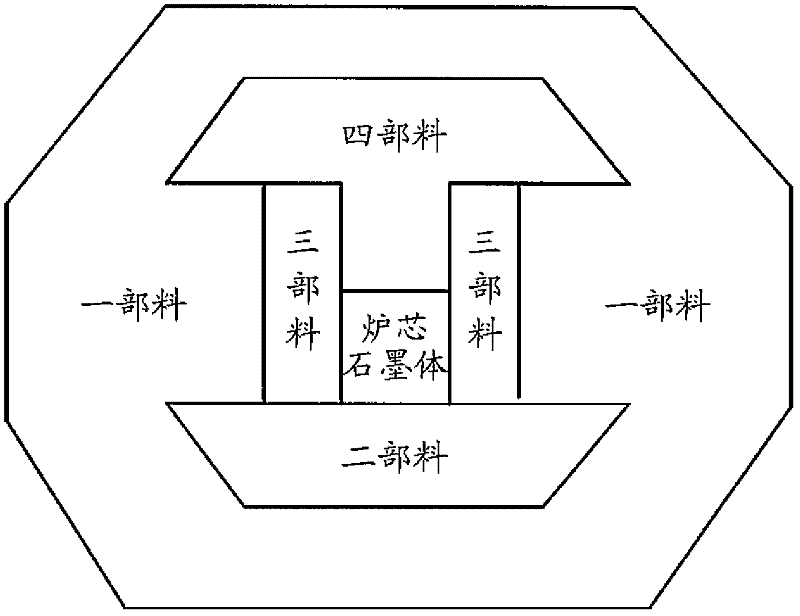

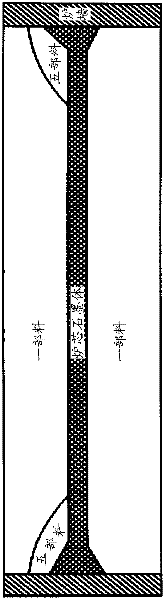

Method for melting green silicon carbide from smokeless ultra low-ash pure coal and green silicon carbide prepared therefrom

InactiveCN102351181AReduce manufacturing costStable physical and chemical indicatorsState of artChemical index

The invention provides a novel method for preparing green silicon carbide and the green silicon carbide prepared therefrom. The method first employs smokeless ultra low-ash pure coal to melt green silicon carbide; a main carbon raw material of petrol coke used in a prior art is substituted, so as to substantially reduce production costs of green silicon carbide and control difficulty of a melting process and enhance product quality; besides, the ultra low-ash pure coal has stable physical and chemical indexes and resource, and can satisfy long-term production.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

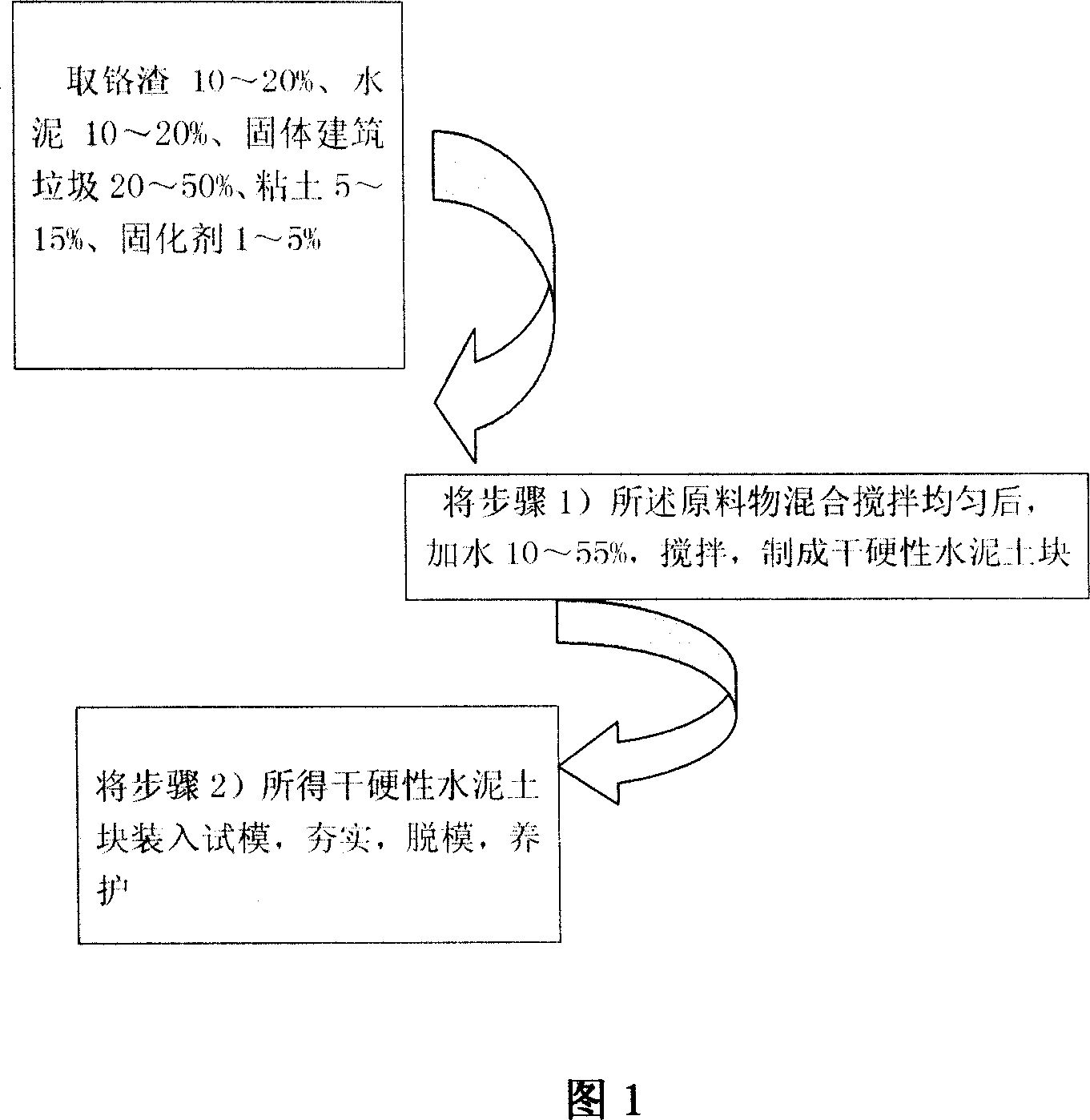

Construction curing agent and application thereof in chromic slag building block

The invention discloses an architectural hardener and application in the chromium slag building brick, which comprises the following parts: 30-50% calcium aluminate, 30-40% silica, 10-20% bivalent ferric material, 5-10 % tourmaline and 5-7% solid water glass. The making method comprises the following steps: 1) feteching 10-20% chromium, 10-20% cement, 20-50% solid architectural rubbish, 5-15% clay and 1-5% hardener; 2) mixing these raw materials to stir evenly; adding 10-55% water; stirring; making dry hard cement clod; 3) loading the cement into specimen mold; pressing; stripping; culturing.

Owner:石一彤

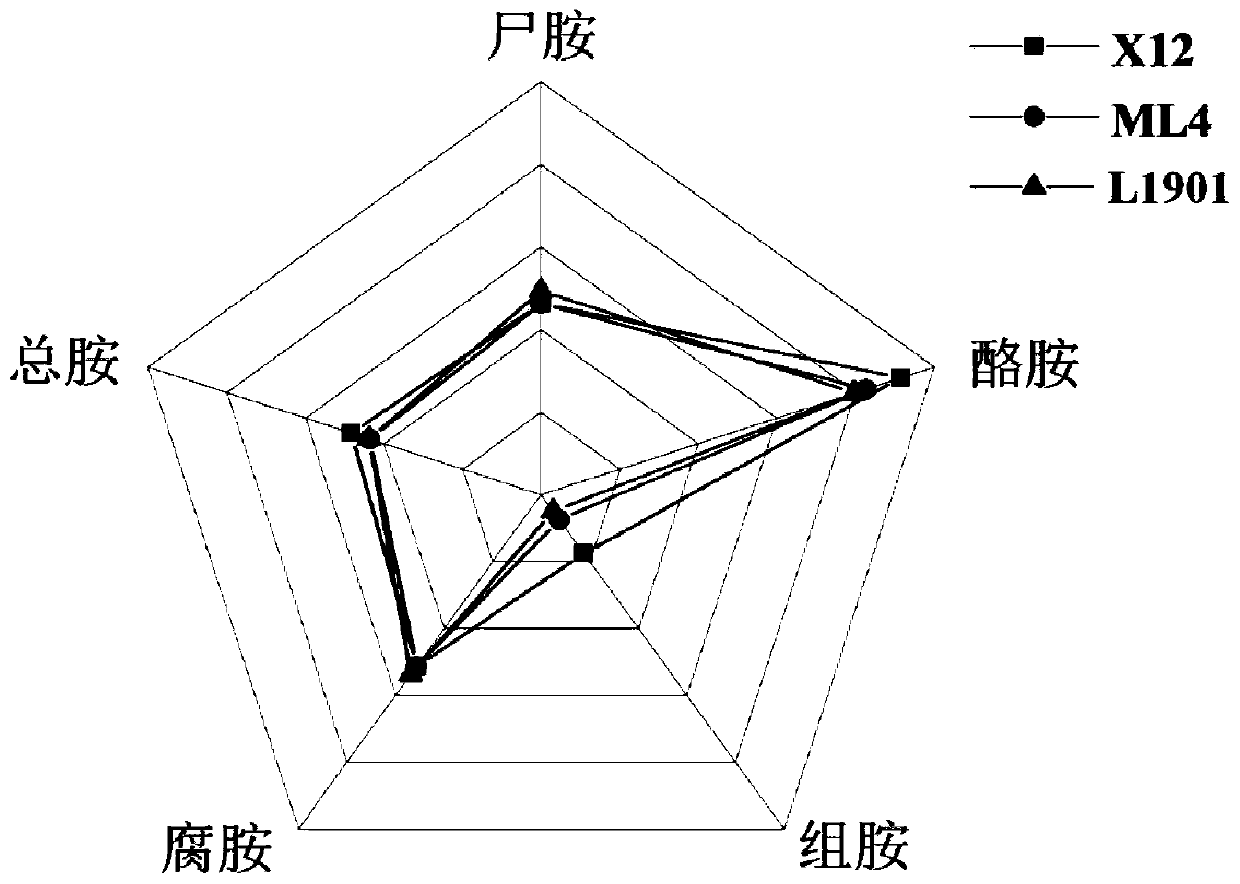

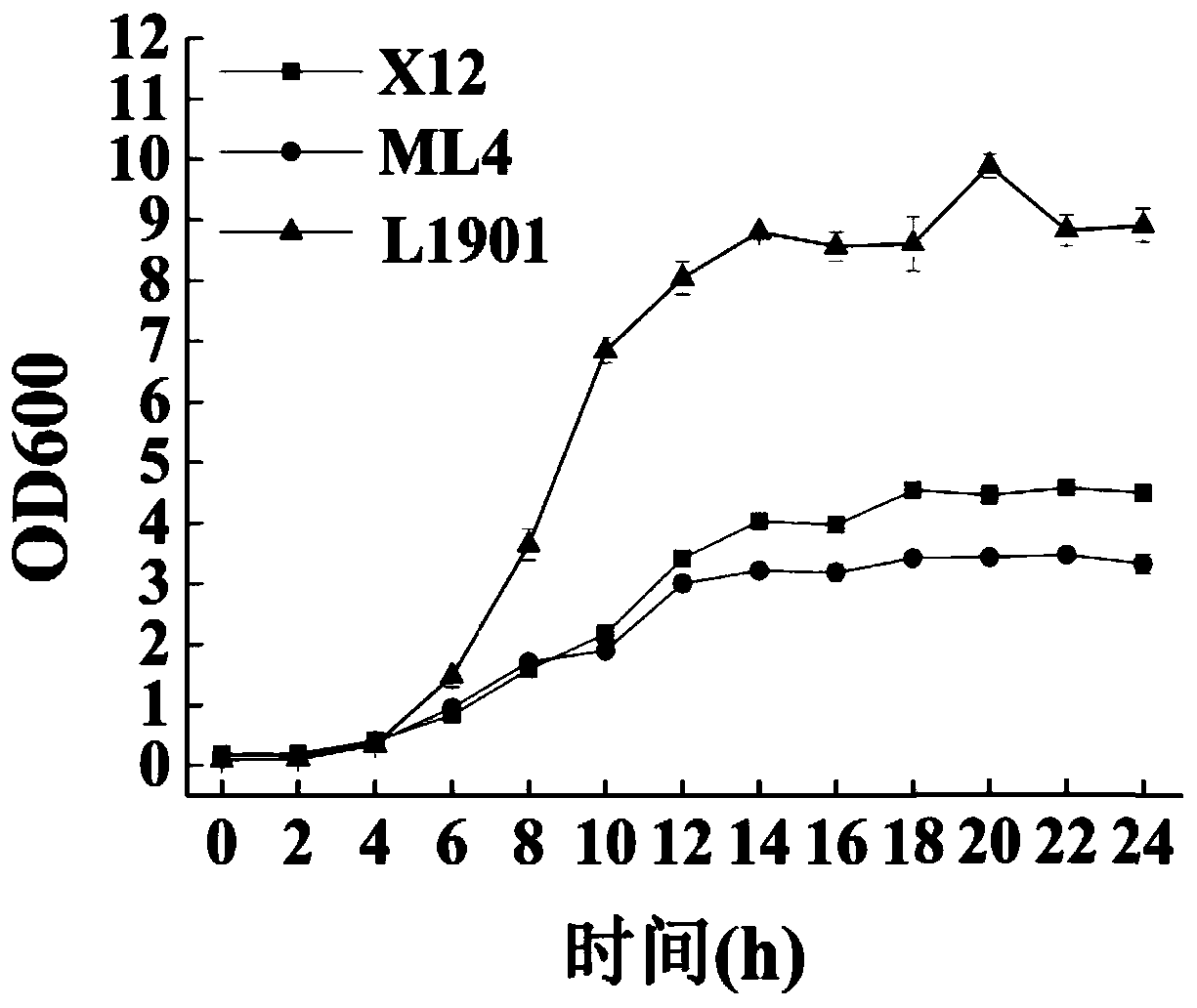

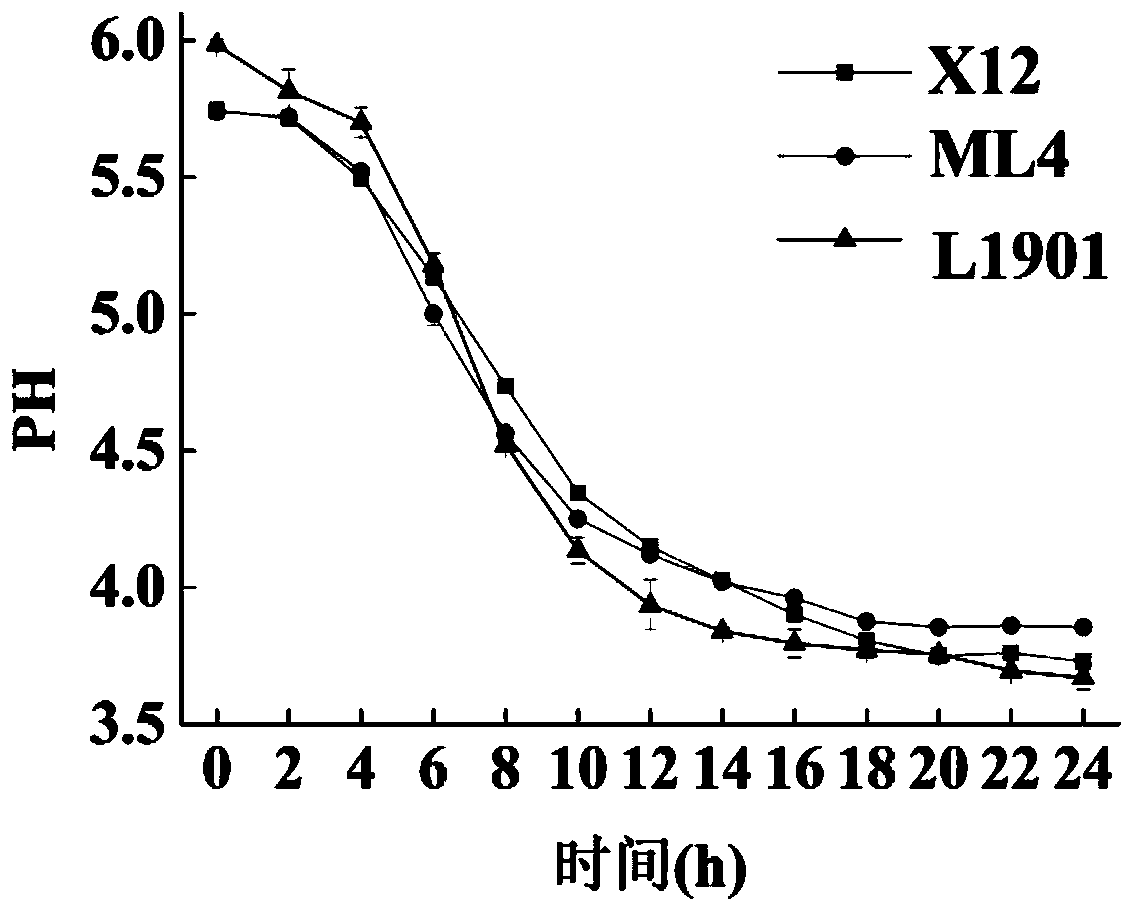

Method for reducing biogenic amine through cyclic rice soaking by inoculating lactobacillus plantarum not generating biogenic amine

ActiveCN110747143AIncrease the rate of acid productionShorten the soaking timeBacteriaAlcoholic beverage preparationBiotechnologyMicrobiology

The invention discloses a method for reducing biogenic amine through cyclic rice soaking by inoculating lactobacillus plantarum not generating the biogenic amine, and belongs to the technical field offood processing and manufacturing. The lactobacillus plantarum is inoculated in the rice soaking process of a grain product; the result shows that by inoculating the lactobacillus plantarum, the content of the biogenic amine in rice soaking water can be effectively reduced, so that the rice soaking water is clear; and conditions are created for the cyclic utilization of rice milk water.

Owner:JIANGNAN UNIV +2

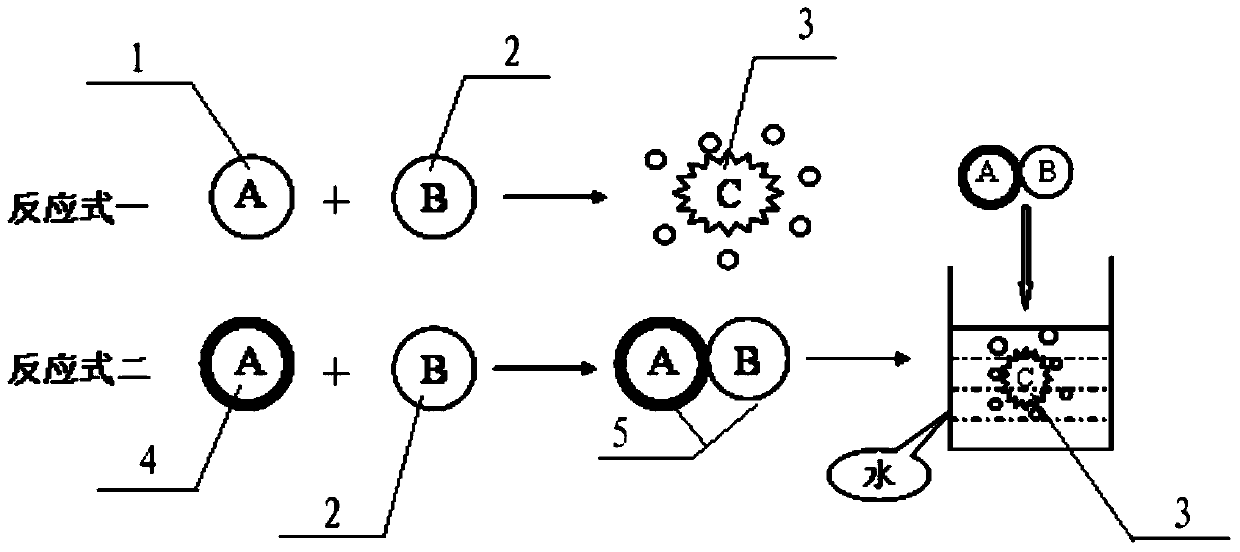

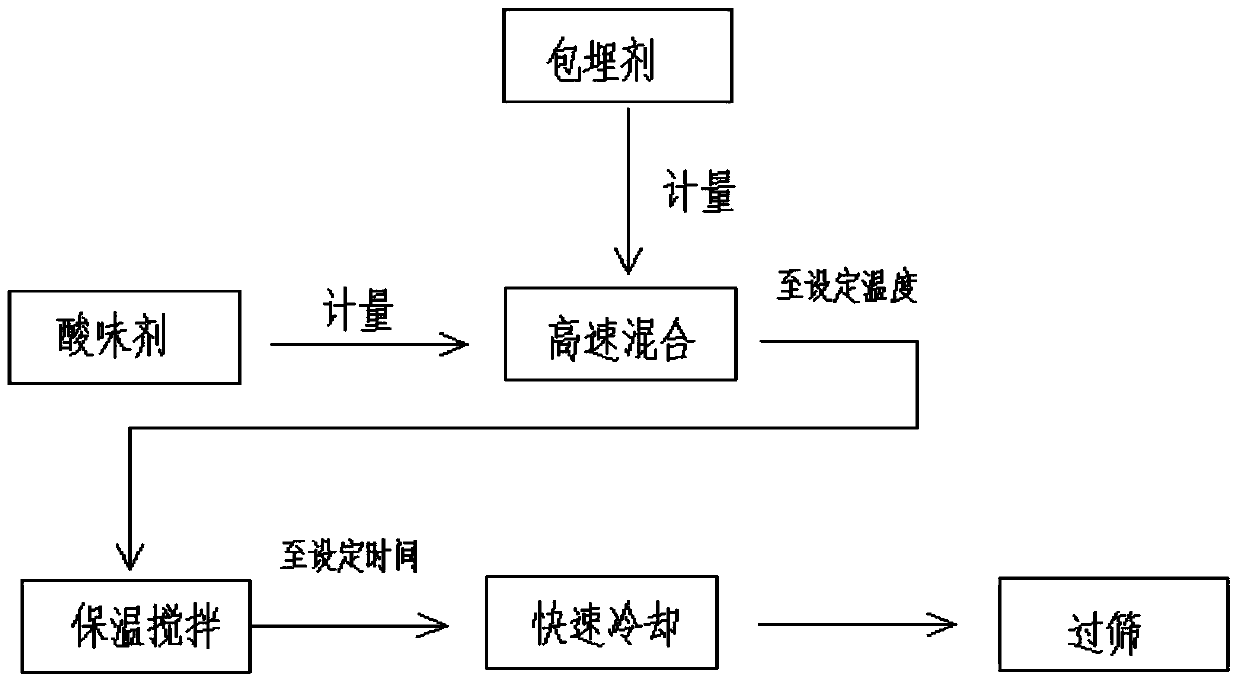

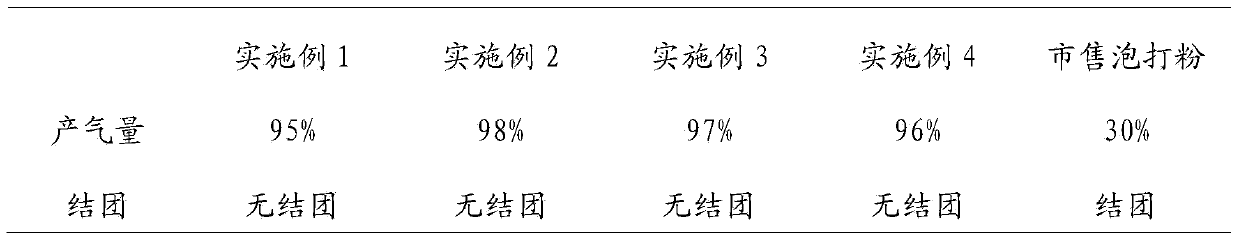

Method for embedding baking powder acidulant

InactiveCN103461750AStable physical and chemical indicatorsGuaranteed effective gas productionFood preparationAcidulantProduction rate

The invention relates to a method for embedding a baking powder acidulant, which comprises the steps of 1, placing an embedding agent and the acidulant into a feeding device, and feeding materials in a high-speed mixer by using the feeding device under the condition that the weight ratio of the acidulant to the embedding agent is 100:(0.1-5); 2, embedding a mixture of the embedding agent and the acidulant in the high-speed mixer, and adjusting the rotating speed of the high-speed mixer so that the temperature of the mixture is kept at 50-80 DEG C, wherein the embedding time is 2-10 min; 3, after the mixture is automatically discharged from the high-speed mixer, cooling the obtained product so as to obtain an acidulant subjected to embedding. The method disclosed by the invention has the advantages that 1, a situation that the quality of baking powder is stable during the shelf life is ensured, and the method solves the problems troubling enterprises for a long time that in traditional production processes, the baking powder is agglomerated and the dosage of the baking powder is reduced during the shelf life; 2, after the acidulant is embedded, the effective gas production rate of the baking powder is ensured, so that the quality of the baking powder is enhanced, thereby achieving an effect on reducing the raw material loss of the baking powder, and creating considerable economic benefits for enterprises.

Owner:GUILIN HONGXING CHEM

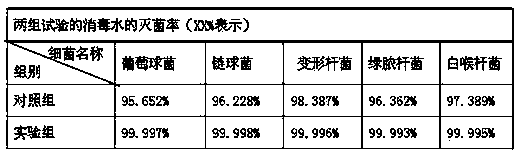

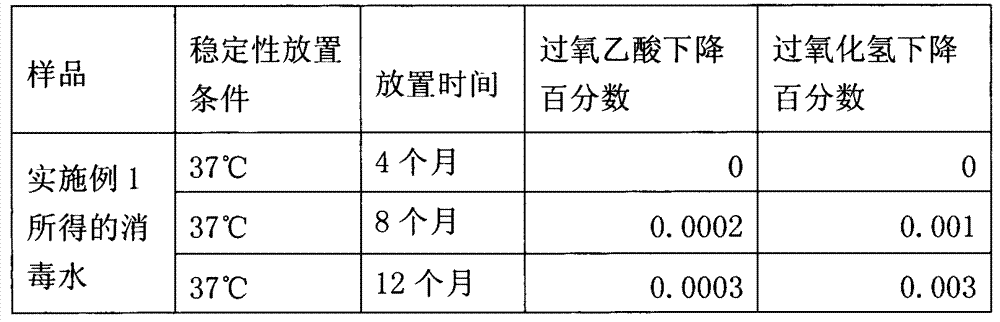

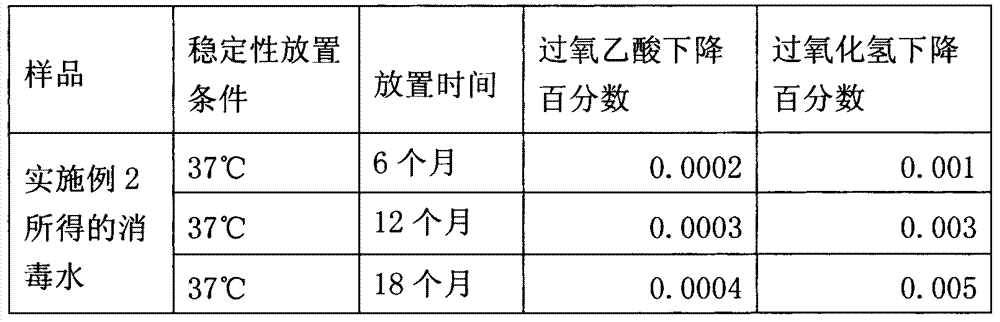

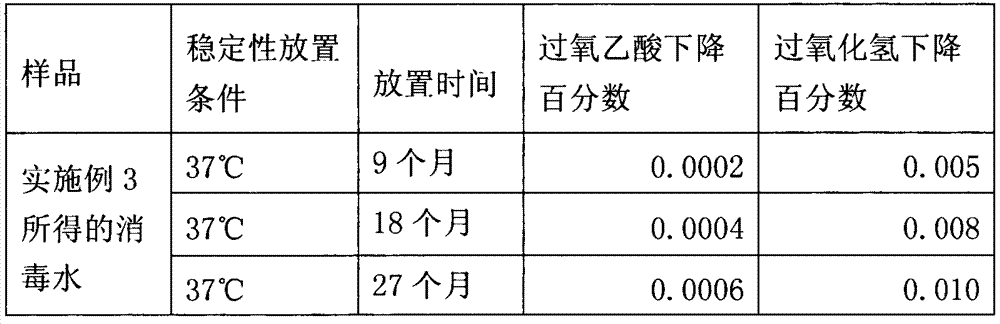

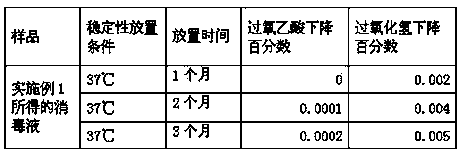

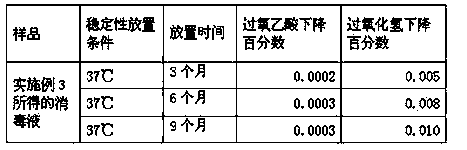

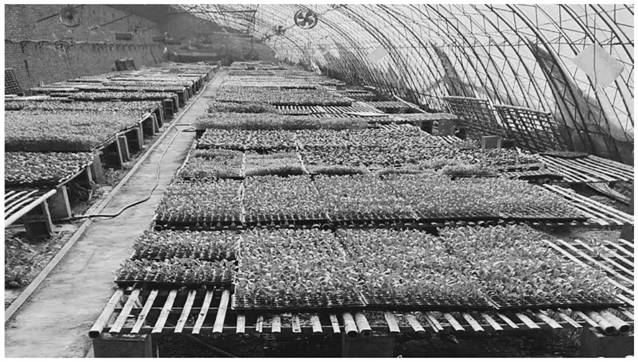

Disinfectant fluid used for washing CT units and preparation method thereof

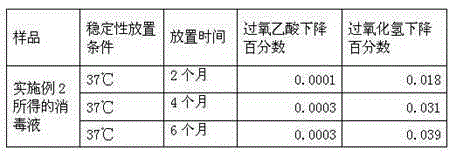

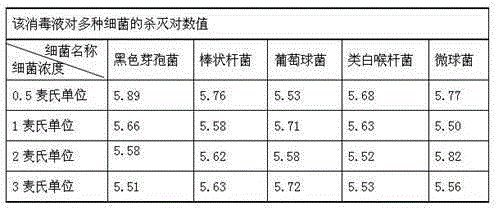

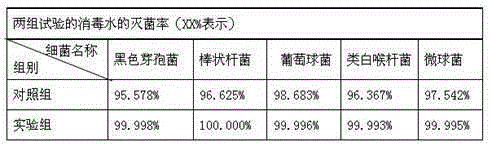

The invention discloses a disinfectant fluid used for washing CT units. The disinfectant fluid contains the following components by weight percent: 0.5-1.0% of quinoline, 2.0-5.0% of hydrogen peroxide, 0.1-0.5% of peroxyacetic acid, 0.5-1.5% of trichloroisocyanuric acid, 2.0-8.0% of ethanol, 3.0-6.0% of benzalkonium chloride and the balance of water. The disinfectant fluid has the beneficial effects that the production cost of the disinfectant fluid is low; the preparation process is simple; the process conditions are easy to achieve; the product stability is good.

Owner:张光荣

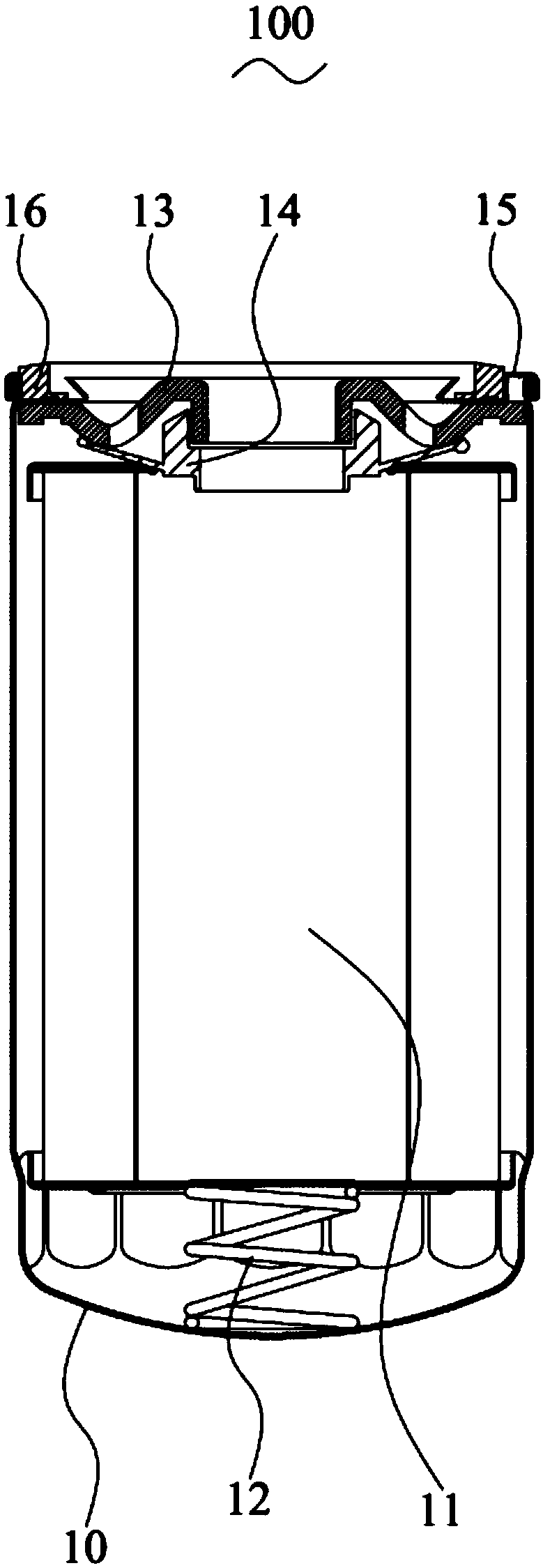

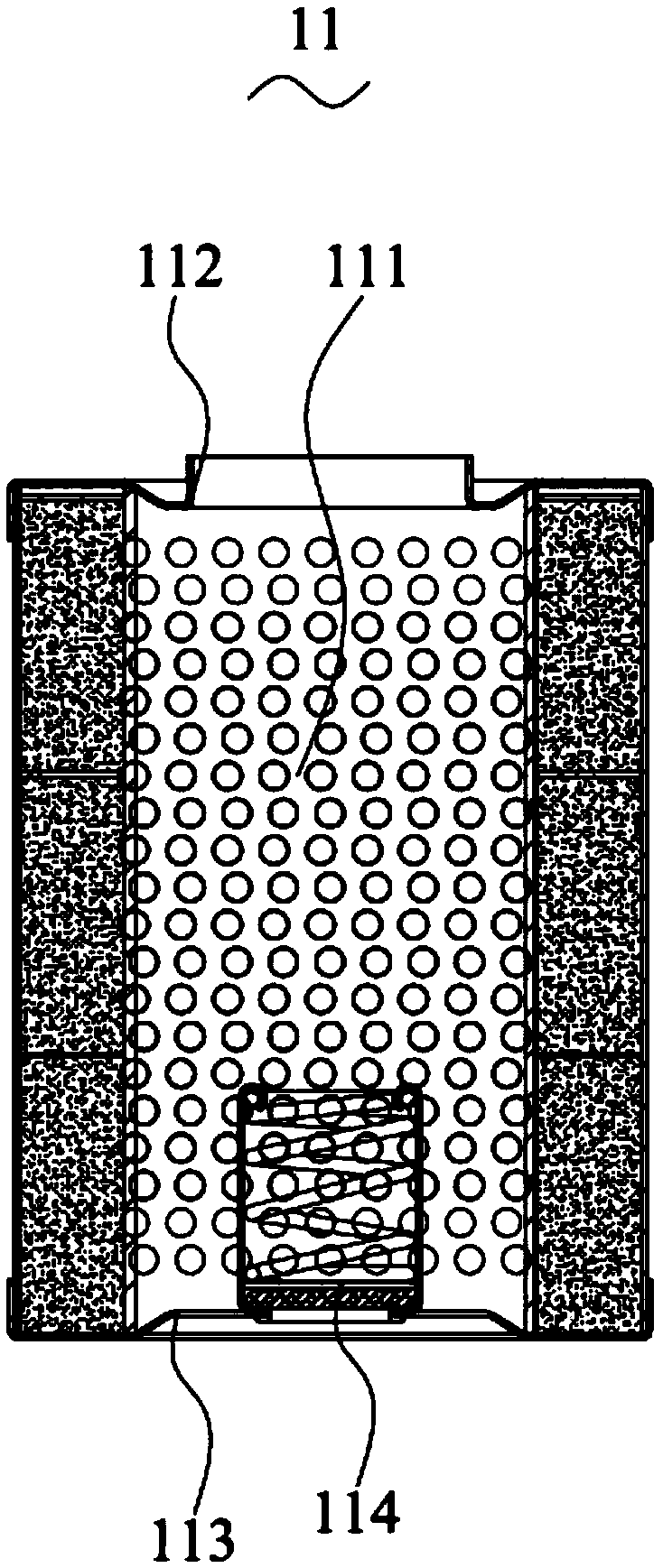

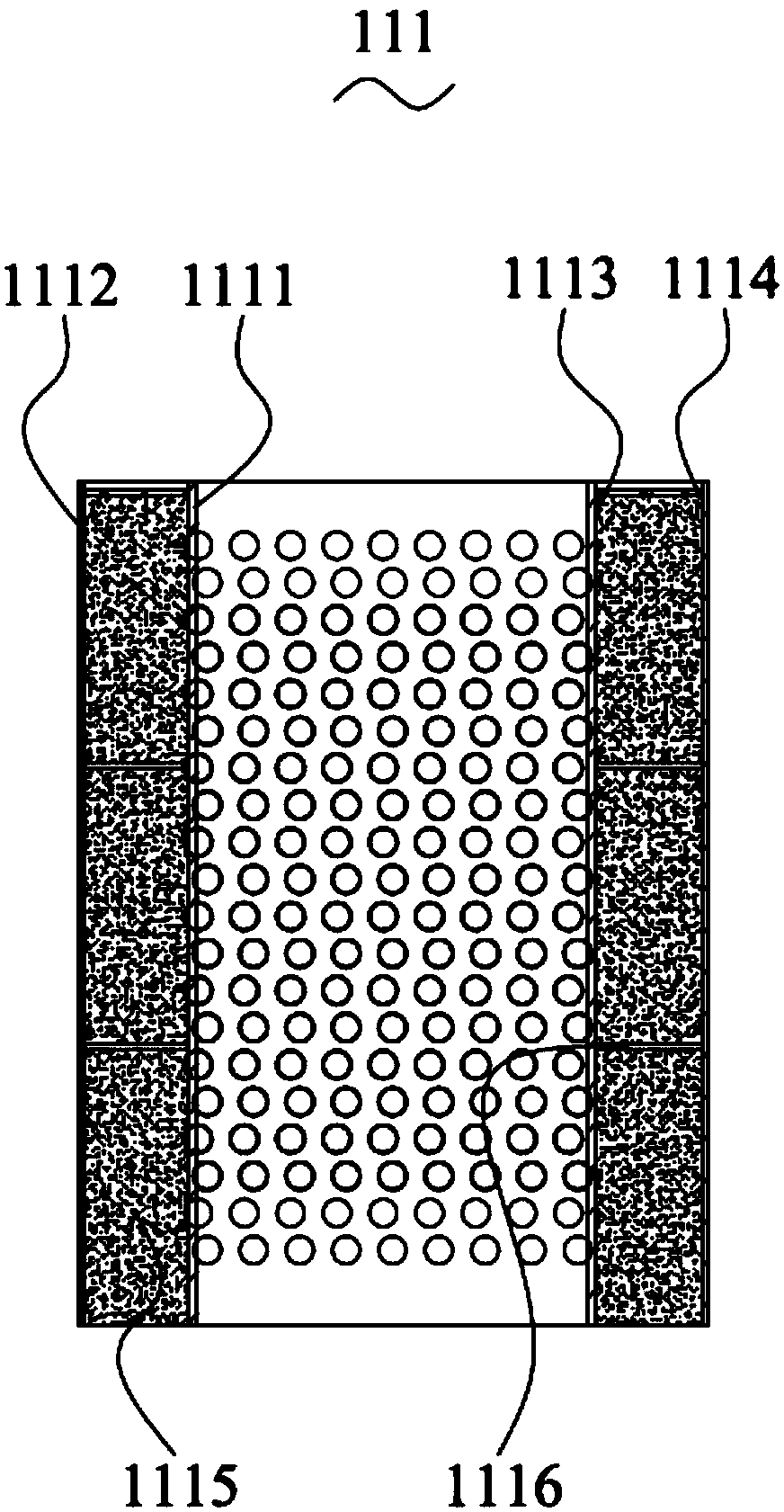

Filter element and filter comprising filter element

PendingCN108999672AExtended service lifeAvoid stockpilingPressure lubricationLubricant mounting/connectionFiberEngineering

A filter element comprises a core. The core comprises an inner pipe and an outer pipe which are coaxially arranged. Evenly-distributed filter holes are formed in the pipe walls of the inner pipe and the outer pipe. A circle of inner filter net is attached to the outer wall of the inner pipe. A circle of outer filter net is attached to the inner wall of the outer pipe. The part between the outer filter net and the inner filter net is filled with filter materials, wherein the filter materials are manufactured through plant fiber containing a low-zinc-value additive. A plurality of annular isolation pads for isolating the filter materials are arranged between the outer filter net and the inner filter net. The filter materials are manufactured through the plant fiber, so that cost is low; after the low-zinc-value additive is added, the physicochemical indexes of online lubricating oil can be stabilized for a long time through the filter materials, and the service life of the online lubricating oil is effectively prolonged. In addition, through the isolation pads, stacking of the filter materials due to gravity can be prevented, the filter element is not prone to blockage, accordingly,the service life of the filter element is prolonged, and frequent filter element replacement is not needed. In addition, the invention further provides a filter comprising the filter element.

Owner:江西福莱特过滤材料有限公司

Solution for sterilizing and cleaning hemodialysis machine and preparation method of solution

ActiveCN104041511AAppearance colorless and transparentStable physical and chemical indicatorsBiocideFungicidesChemistryPyrophosphate

The invention discloses a solution for sterilizing and cleaning a hemodialysis machine and a preparation method of the solution. The solution is prepared from peroxyacetic acid, hydrogen peroxide, water, glacial acetic acid and sodium pyrophosphate. The preparation method comprises the following steps: putting water, glacial acetic acid and sodium pyrophosphate into a solution preparing tank to prepare an inert solution; stirring for dissolving for 30 minutes; adding peroxyacetic acid and hydrogen peroxide in the solution preparing tank to obtain a mixed solution; and filtering the mixed solution through a three-section type membrane filter and performing filling to obtain the product. The product has stable performance and a validity period lasting for two years long, and is capable of effectively exterminating intestinal tract pathogenic bacteria, pyogenic cocci, pathogenic yeasts and bacterial spores.

Owner:海南朗腾医疗设备有限公司

Disinfectant fluid for cleaning oxygen mask for cardiovascular internal medicine and preparation method thereof

InactiveCN104509552AAppearance colorless and transparentStable physical and chemical indicatorsBiocideFungicidesCentella asiatica extractDisinfectant

The invention discloses a disinfectant fluid for cleaning an oxygen mask for cardiovascular internal medicine; the disinfectant fluid comprises the following components by weight: 1-3 parts of peroxyacetic acid, 1-5 parts of hydrogen peroxide, 3-6 parts of metronidazole, 4-9 parts of phenol, 6-10 parts of bohadschia graeffei, 2-6 parts of sodium hypochlorite, and 1-5 parts of a herba centellae extract. The developed disinfectant fluid for ward internal disinfection is colorless and transparent in appearance and stable in physical and chemical indicator performance, generates no crystallization, turbidity and precipitates during use, and has physical and chemical indicators showed stably. Compared with the prior art, the prepared disinfectant has the advantages of low production cost, simple preparation process, easy realization of process conditions, and good product stability; and a volatile oil extracted from traditional Chinese medicines is added, the smell is aromatic, and patients feel blissfully happy.

Owner:聂文红

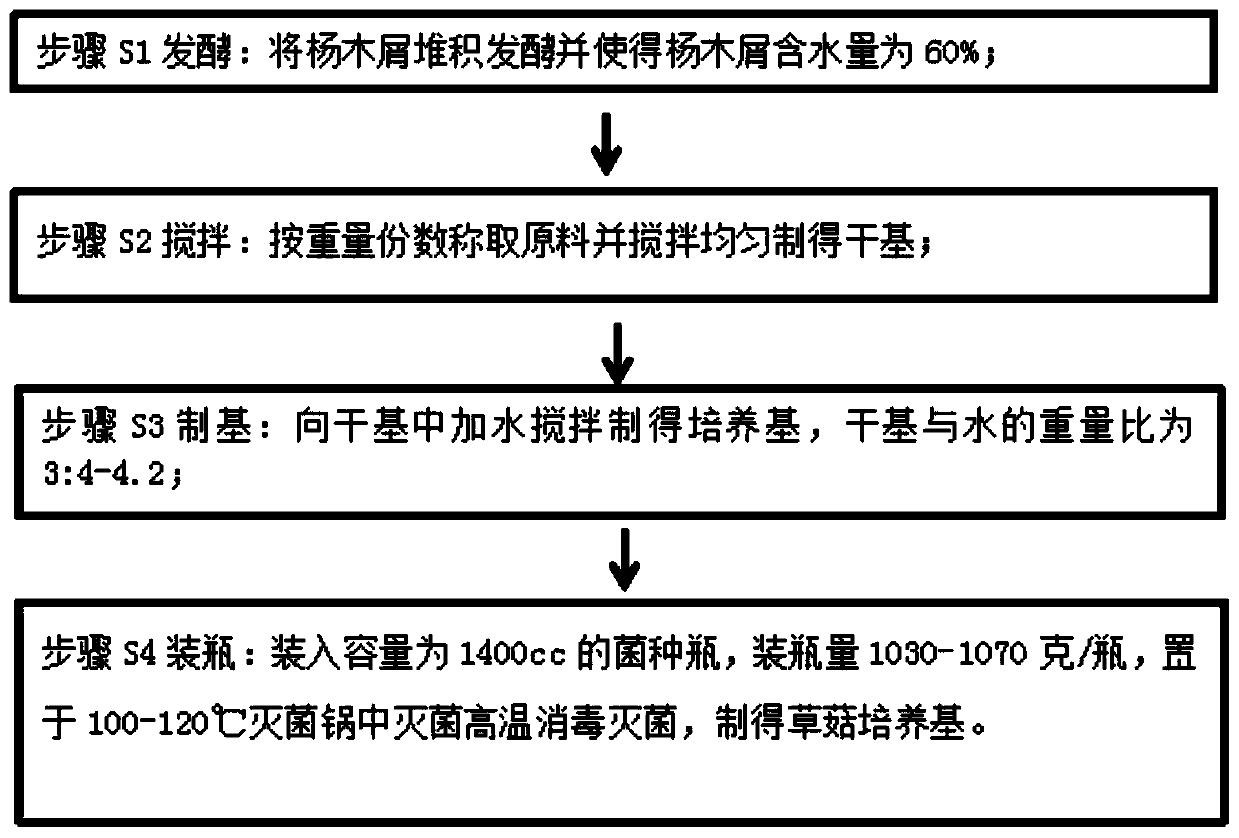

Poplar sawdust complex medium suitable for planting hypsizygus marmoreus and preparation method thereof

InactiveCN111492895AApplicable carbon to nitrogen ratioExtended shelf lifeCultivating equipmentsMushroom cultivationCalcium hydroxideSoybean hulls

The invention discloses a poplar sawdust complex medium suitable for planting hypsizygus marmoreus and a preparation method thereof. The raw materials comprise the following components in percentage by weight: 27% of corn cob, 14.8% of cottonseed hull, 11.1% of bran, 20.8% of rice bran, 16.3% of poplar sawdust, 4.2% of soybean hull, 1.7% of sugar beet pulp, 2.4% of culture soil, 1.0% of light calcium carbonate and 0.7% of calcium hydroxide. The invention provides a poplar sawdust complex formula suitable for planting the hypsizygus marmoreus. The formula is abundant in nutrient and appropriatein carbon-nitrogen ratio; the poplar sawdust is wide in source in northern Jiangsu province, low in price and high in lignin content, and can be perennially supplied in a factory planting process; and the planted hypsizygus marmoreus is good in quality.

Owner:江苏华绿生物科技股份有限公司

Disinfectant used for washing red light therapeutic instruments and preparation method thereof

InactiveCN104206414AAppearance colorless and transparentReduce manufacturing costBiocideDisinfectantsDisinfectantSalicylic acid

The invention discloses a disinfectant used for washing red light therapeutic instruments. The disinfectant contains the following components by weight percent: 0.5-1.0% of peroxyacetic acid, 2.0-5.0% of hydrogen peroxide, 0.1-0.5% of pyridine-2-carboxylic acid, 0.01-0.05% of sodium citrate, 1.0-5.0% of salicylic acid, 2.0-6.0% of ethanol and the balance of water. The disinfectant has the beneficial effects that the production cost of the disinfectant is low; the preparation process is simple; the process conditions are easy to achieve; the product stability is good.

Owner:SHANDONG PROVINCIAL HOSPITAL

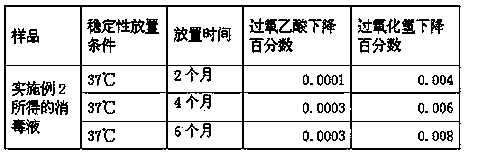

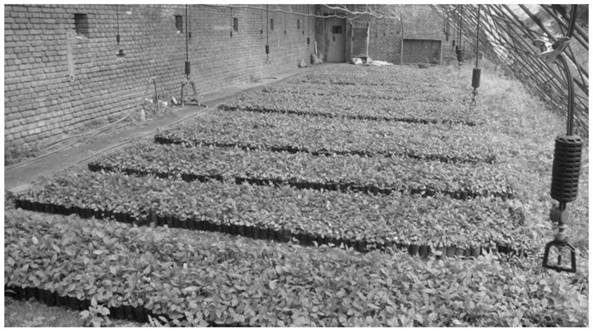

Aronia melanocarpa greenhouse turfy soil hole tray twig cutting seedling raising method

ActiveCN112889504AShort breeding cycleImprove efficiencyClimate change adaptationGrowth substratesTwigSeedbed

The invention discloses an aronia melanocarpa greenhouse turfy soil hole tray twig cutting seedling raising method. The aronia melanocarpa greenhouse turfy soil hole tray twig cutting seedling raising method comprises the following steps that S1, a turfy soil matrix and a hole tray are sterilized, a seedbed base is erected, the hole tray is put on the seedbed base, and spraying is carried out until the matrix is saturated in moisture for later use; S2, new branches are cut, and flower buds are removed as cuttings; S3, the cuttings are cut to obtain cutting slips, and the roots of the cutting slips are soaked into a rooting agent aqueous solution for intermediate-speed dipping; S4, the seedbed is sprayed before cutting, the relative humidity in the greenhouse is kept, and the cuttings are cut on the hole tray; and S5, before rooting of the cutting slips, the light transmittance, temperature and humidity in the greenhouse are controlled, and after rooting of the cutting slips, the temperature and humidity in the greenhouse are adjusted. By means of the aronia melanocarpa greenhouse turfy soil hole tray twig cutting seedling raising method, 50-60 days after cutting of the scions, the scions and the hole trays can be integrally transplanted outdoors to be returned to a nursery for seedling hardening, cutting can be carried out in the greenhouse for 2-3 seasons every year, large-scale production and industrialized seedling raising are achieved, the seedling raising period is short, and the efficiency is high.

Owner:辽宁省旱地农林研究所

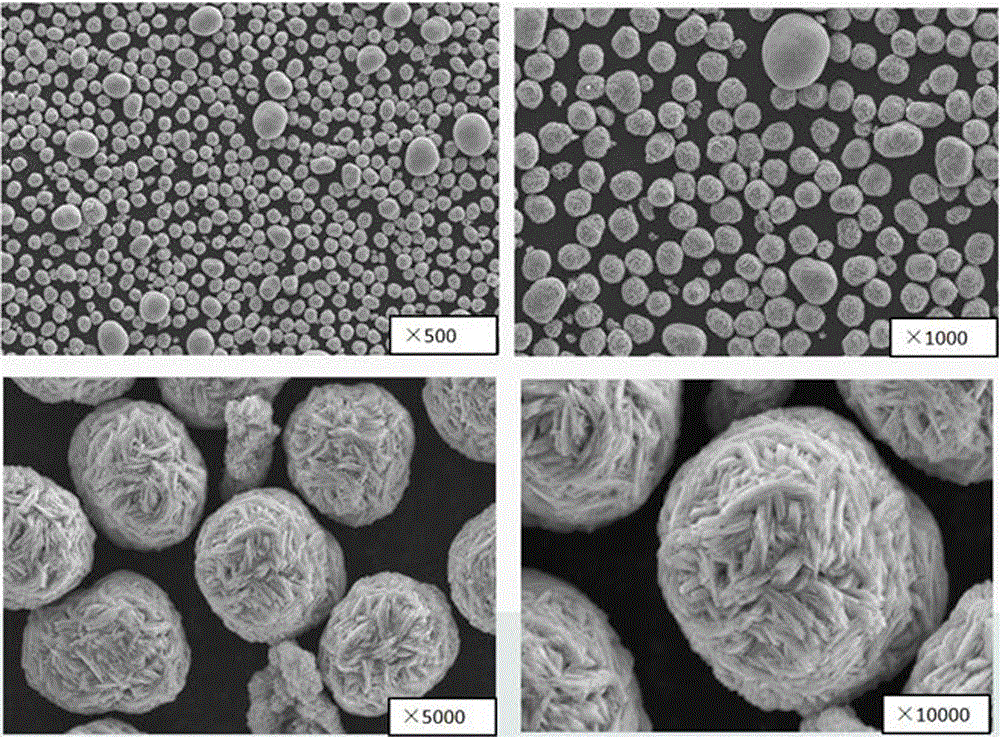

Preparation method of NCA precursor

InactiveCN106365211AUniform content of powder elementsLess impuritiesNickel oxides/hydroxidesAluminium sulfateWater soluble

The invention discloses a preparation method of an NCA precursor. The preparation method comprises the following steps: mixing water-soluble salt of Ni and water-soluble salt of Co, and preparing into an aqueous solution to obtain a mixed ion solution, wherein in the mixed ion solution, the concentration of mixed ions comprising Ni<2+> and Co<2+> is in the range of 0.8-2.3 mol / L; preparing a mixed alkali liquid: preparing a sodium hydroxide solution with the concentration of 0.5-4.0 mol / L first, then adding a certain amount of aluminum sulfate solid with the concentration of 0.2-0.5 mol / L, completely dissolving, adding ammonia water with the concentration of 0.05-1.0 mol / L to obtain the mixed alkali solution II; continuously adding the mixed ion solution into a reactor, performing an equimolar synthesis reaction on the mixed ion solution and the mixed alkali solution, and constantly adjusting the flow rate to stabilize the pH during the reaction; performing solid-liquid separation on a synthetic product in the step, washing obtained solid, and drying to obtain a ternary cathode material NCA precursor.

Owner:宋程

Coupling lubricating solution for B ultrasonic examination

InactiveCN105944119AThe effect of sound transmission is remarkableClear sound effectAntisepticsEchographic/ultrasound-imaging preparationsChemistry

The invention belongs to the technical field of coupling agents and discloses a coupling lubricating solution for B ultrasonic examination. The coupling lubricating solution is prepared according to the following process: step (1), mixing, stirring and heating; step (2), uniformly stirring; step (3), heating and stirring; step (4), extracting with ethanol; and step (5), stirring, sub-packaging and sealing. The coupling lubricating solution has stable physicochemical index performances and has disinfection and sterilization effects.

Owner:孙百梅

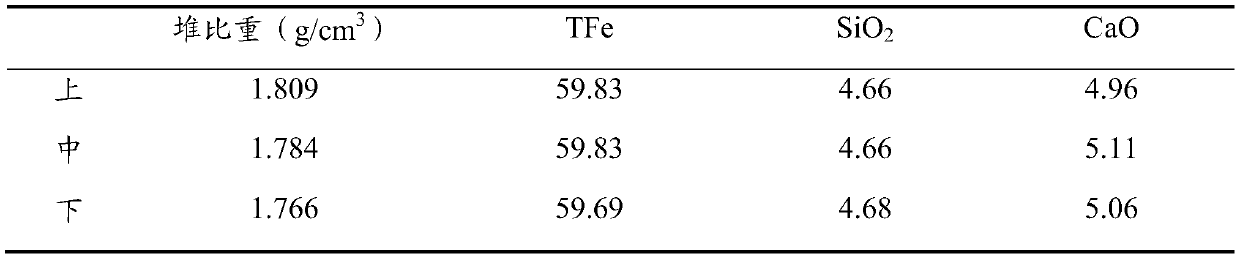

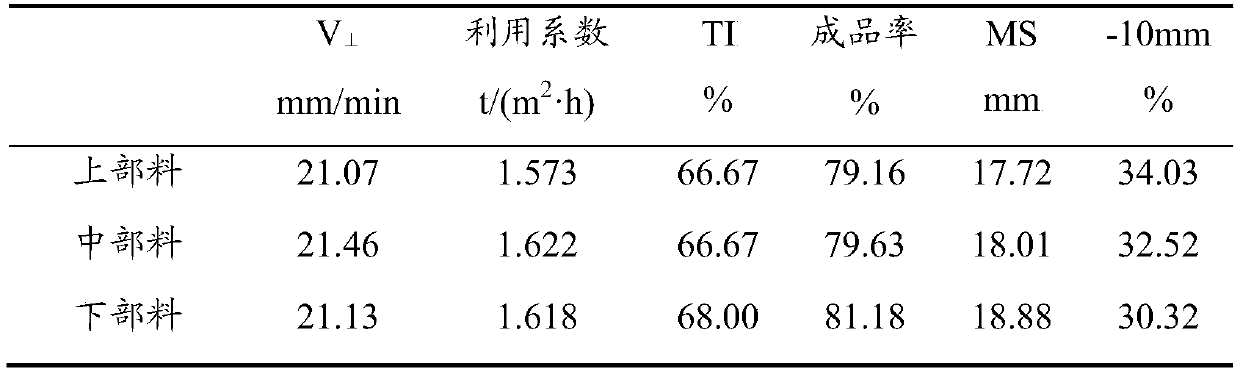

Blending ore piling method and blending ore

InactiveCN110029219AImprove distributionExtended contact mixing timeAdditive ingredientBlast furnace smelting

The invention belongs to the technical and economic field of blast furnace smelting, and relates to a blending ore piling method and blending ore. The blending ore piling method comprises the steps that iron materials, flux and fuel are prepared in advance to form blending ore with the fixed matching ratio, and the blending ore is transferred into a secondary material field. According to the blending ore piling method, the iron materials, the flux and the fuel are prepared in advance to form the blending ore with the fixed matching ratio and uniform ingredients, contact and blending time of the flux, the fuel and ore powder is prolonged, the distribution state of the flux and the fuel in sintering of the concentrate powder is improved, and the sintered ore forming efficiency is improved.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Disinfectant for B-mode ultrasound probe and preparation process of disinfectant

InactiveCN106035391AStable physical and chemical indicatorsReduce manufacturing costBiocideDisinfectantsTriclosanDisinfectant

The invention belongs to the technical field of disinfectants, and discloses a B-ultrasound probe disinfectant, which is prepared from the following raw materials: ethanol, o-phenylphenol, glycerin, dichlorophenoxychlorophen, methyl p-hydroxybenzoate, amino polysaccharides, Sodium Lauryl Sulfate, Vitamin E, Deionized Water, Potassium Iodide, Aluminum Hydroxychloride, Honeysuckle, Black Pepper. The invention adopts the method of combining the chemical disinfectant and the plant extract fungicide, reduces the dosage of the chemical disinfectant, and has good compatibility and synergistic effect.

Owner:于甜甜

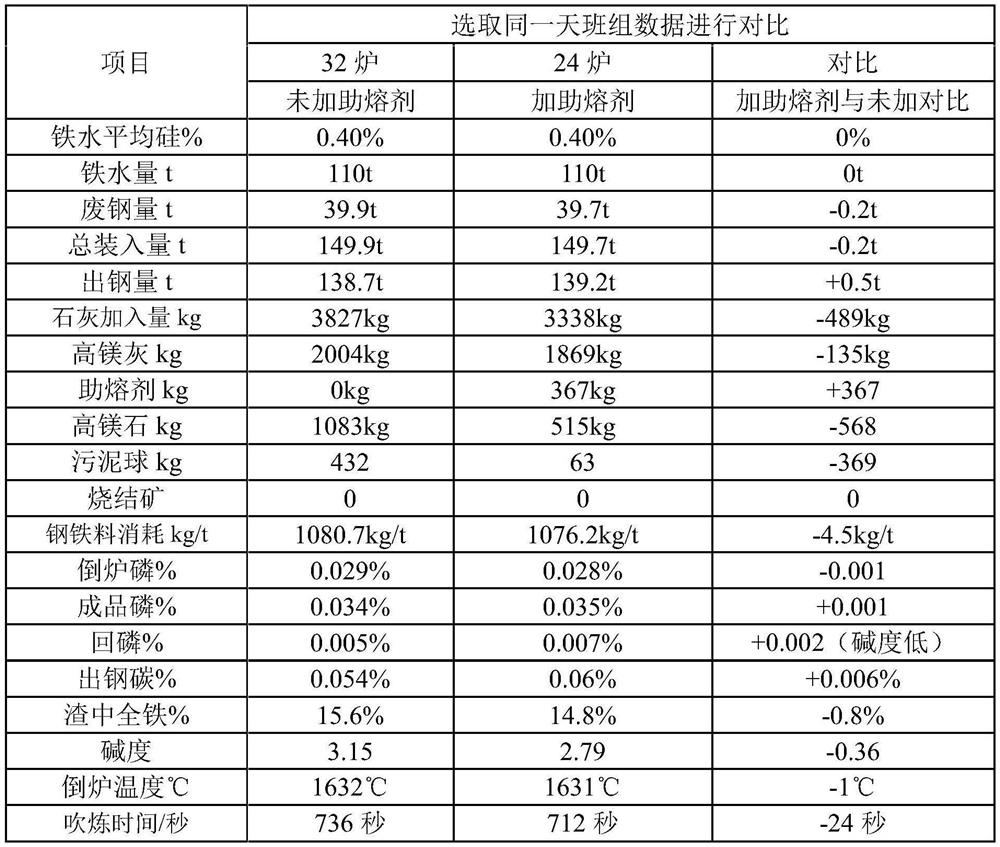

Fluxing agent and use method thereof

ActiveCN114369696AInhibition formationFast meltingManufacturing convertersHigh activityMelting point

The invention discloses a fluxing agent and a use method thereof, the fluxing agent is a powdery pressed ball, and the physicochemical indexes are relatively stable; after being added into a furnace, the fluxing agent is rapidly decomposed into small particles in a high-temperature environment, the fluxing agent is prepared through briquetting and is a blocky fluxing agent, the lime content of the fluxing agent is far higher than that of an existing slagging agent and is matched with the components of FeO and SiO2, and when the fluxing agent is added into the steelmaking slagging process, due to the fact that the lime content is high, the activity is high, and slagging is rapid, the fluxing agent can be rapidly decomposed into small particles. And meanwhile, the formation of a high-melting-point compound C2S is prevented, the melting speed of the slag is greatly increased, and the dephosphorization effect in the blowing process is obviously enhanced.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Disinfectant for cleaning and disinfecting hemodialysis machine and preparation method thereof

ActiveCN104206413BAppearance colorless and transparentStable physical and chemical indicatorsBiocideDisinfectantsHemodialysisHaemodialysis machine

The invention discloses a disinfectant solution for cleaning and disinfecting hemodialysis machines. The product contains 0.5%-1.0% of peracetic acid, 2.0%-5.0% of hydrogen peroxide, and 0.1% of pyridine-2-carboxylic acid in terms of components by weight. %-0.5%, sodium citrate 0.01%-0.05%, sodium dichloroisocyanurate 0.2%-2.0%, sulfamic acid 0.05%-1.0%, and the balance is water. The invention has the advantages of simple preparation process, convenient use, easy realization of process conditions and good product stability.

Owner:南通江海港建设工程有限公司

A sterilizing agent used for apparatus in a room for B-scan ultrasonography and a preparing method thereof

ActiveCN106075500AEasy to wipe offStable physical and chemical indicatorsBiocideDead animal preservationB-scan ultrasonographyChemistry

The invention belongs to the technical field of medical sterilizing agents and discloses a sterilizing agent used for apparatus in a room for B-scan ultrasonography. The sterilizing agent is prepared by steps of 1) mixing and stirring, 2) stirring and allowing the mixture to stand, 3) fully stirring, 4) heating and stirring, 5) extracting with ethanol, concentrating and crushing and 6) stirring, subpackaging and sealing. The sterilizing agent is stable in performance and simple in preparing process.

Owner:刘敏

Disinfectant for radiotherapy department

InactiveCN106035390AReduce dosageEasy to wipe offBiocideDead animal preservationDisinfectantCombinatorial chemistry

The invention belongs to the technical field of medical disinfectants and discloses a disinfectant for the radiotherapy department. The disinfectant is prepared according to the following process which comprises a step 1) of preparing a material A, a step 2) of preparing a material B, a step 3) of preparing a material C, a step 4) of preparing a material D, a step 5) of preparing a material E and a step 6) of preparing the disinfectant. The disinfectant is good in sterilizing effect, high in stability and wide in application prospect.

Owner:寻航

Biological orgamic fertilizer and preparation thereof

ActiveCN100396652CAdvanced production technologyLong duration of high temperatureBio-organic fraction processingBacteriaBiotechnologyMicroorganism

This invention relates to a method to prepare a kind of bioorganic fertilizer and its application. The preparation method includes following steps: a) proliferation and cultivation of microorganism species; b) cultivation of microorganism species against stalk antibody; c) adsorption onto a carrier and drying into organic decomposers; d) preprocessing of organic waste; e) inoculation complex fermentation and f) continuous high-temperature fermentation and nontoxification. This invention has the advantages of advanced technique, low production cost, stable product quality and long fertility persistence and can be widely applied in the production of corns, vegetables, fruits and all kinds of economic crops. Besides, it is a green method makes considerable economic, social and environmental benefits.

Owner:上海联业农业科技有限公司

Sterilizing agent for radiation room instruments and preparation process thereof

InactiveCN106035389AReduce dosageGood synergistic effectBiocideDisinfectantsChemistryMethyl hydroxybenzoate

The invention belongs to the technical field of medical fungicides, and discloses a fungicide used for radiation room instruments, which is prepared from the following raw materials: polyhexamethylene guanidine, water-soluble chitosan, vitamin E, deionized water, Potassium iodide, aluminum hydroxychloride, honeysuckle, black pepper, ethanol, o-phenylphenol, glycerin, diclofenac, methylparaben. The bactericide of the invention can be applied to disinfection and sterilization in radiology departments, and can effectively kill common bacteria such as Staphylococcus aureus, pneumococcus, Shigella and Escherichia coli in hospitals.

Owner:寻航

Method for producing nutritive soil for practical and highly efficient soilless flower growth

ActiveCN102696462BRetain nutrientsNutritional diversityAgriculture gas emission reductionCultivating equipmentsRare-earth elementPrill

Owner:郭茂青

Disinfection liquid for B mode ultrasonic room

InactiveCN106035317AImprove the effectShort sterilization timeBiocideDead animal preservationChemistryAnti bacteria

The invention belongs to the technical field of medical disinfectors, and discloses a disinfection liquid for a B mode ultrasonic room. The disinfection liquid is prepared by the following process with the steps of (1) preparation of a mixture A; (2) preparation of a mixture B; (3) preparation of a mixture C; (5) preparation of a mixture E; (6) preparation of the disinfection liquid. The disinfection liquid has the advantages that the anti-bacteria and sterilization functions are strong, and the stability is good.

Owner:于甜甜

Method for manufacturing blast furnace stemming

A preparation method for blast furnace taphole clay has the following processes, bulk raw materials are heated to 20 to 40 DEG C and are mixed evenly, the particle size of the bulk raw materials is 3 to 0.074mm, binder is then added, the mixture is grinned for 40 to 60 minutes, which is then pressed and formed, the additive and each bulk raw material are put into separate holding tank, the binderis put into a holding tank, the raw material is heated to 20 to 40 DEG C in the holding tank, binder is added into the clay mill to be grinned for 40 to 60 minutes, when the temperature is 50 to 70DEG C, material is pressed and formed in a forming machine, the heating method is that lateral heating pipes are arranged outside the equipment, and medium with the melting point equal to or above 100 DEG C is pumped in. The preparation method of the blast furnace taphole clay has low labor intensity and high production efficiency.

Owner:SHANXI LUWEIBAO TAIGANG REFRACTORIES CO LTD

A kind of bactericide used for b-ultrasound room equipment and preparation method thereof

ActiveCN106075500BEasy to wipe offStable physical and chemical indicatorsBiocideDead animal preservationB-scan ultrasonographyChemistry

The invention belongs to the technical field of medical sterilizing agents and discloses a sterilizing agent used for apparatus in a room for B-scan ultrasonography. The sterilizing agent is prepared by steps of 1) mixing and stirring, 2) stirring and allowing the mixture to stand, 3) fully stirring, 4) heating and stirring, 5) extracting with ethanol, concentrating and crushing and 6) stirring, subpackaging and sealing. The sterilizing agent is stable in performance and simple in preparing process.

Owner:刘敏

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com