Construction curing agent and application thereof in chromic slag building block

A building block and curing agent technology, which is applied to a building curing agent and its application in chrome slag building blocks, a curing agent and its environmental protection application field, can solve the problem that hexavalent chromium ions are poisonous, difficult to popularize and apply, and Complex process and other problems, to achieve the effect of process elimination, wide application range and wide material source

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

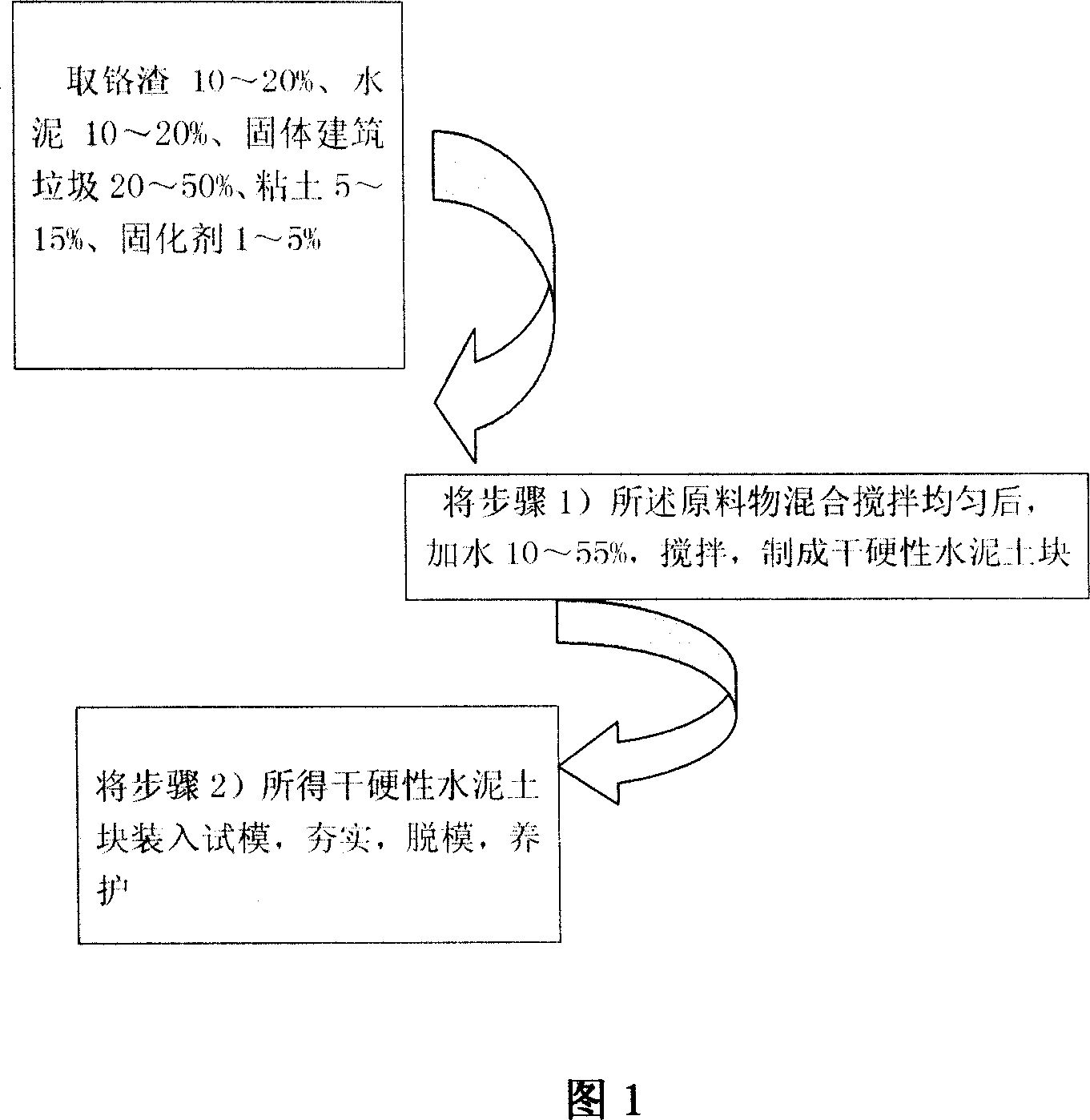

Method used

Image

Examples

Embodiment 1

[0030] As shown in the figure, it is a construction curing agent, which contains: calcium aluminate expansion raw materials, silicon dioxide, ferrous raw materials, calcium carbide gas, and solid water glass.

[0031] The above-mentioned calcium aluminate expansion raw materials, silicon dioxide, divalent iron raw materials, tourmaline and solid water glass are in order by weight percentage:

[0032] Calcium aluminate 40%

[0033] Silica 30%

[0034] Ferrous iron raw materials 15%

[0035] Tourmaline 8%

[0036] Solid water glass 7%

Embodiment 2

[0038] A construction curing agent, which contains: calcium aluminate expansion raw materials, silicon dioxide, divalent iron raw materials, calcium carbide gas, solid water glass.

[0039] The above-mentioned calcium aluminate, silicon dioxide, divalent iron raw materials, tourmaline and solid water glass are in order by weight percentage:

[0040] Calcium aluminate 40%

[0041] Silica 35%

[0042] Ferrous iron raw materials 10%

[0043] Tourmaline 10%

[0044] Solid water glass 5%

Embodiment 3

[0046] A construction curing agent, which contains: calcium aluminate expansion raw materials, silicon dioxide, divalent iron raw materials, calcium carbide gas, solid water glass.

[0047] The above-mentioned calcium aluminate, silicon dioxide, divalent iron raw materials, tourmaline and solid water glass are in order by weight percentage:

[0048] Calcium aluminate 35%

[0049] Silica 35%

[0050] Ferrous iron raw materials 15%

[0051] Tourmaline 10%

[0052] Solid water glass 5%

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com