Method for embedding baking powder acidulant

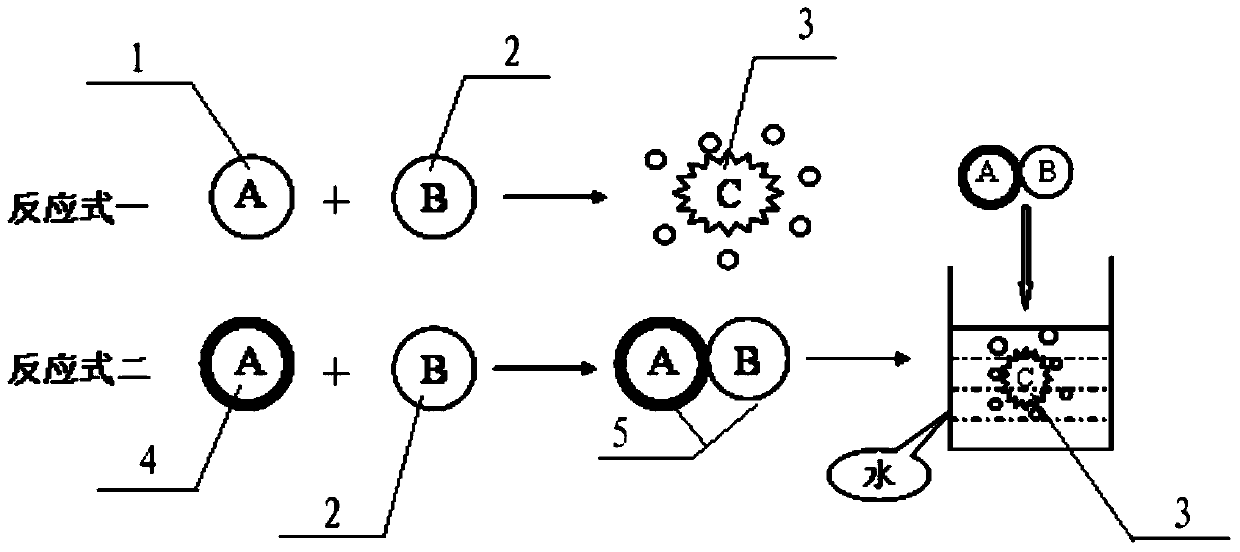

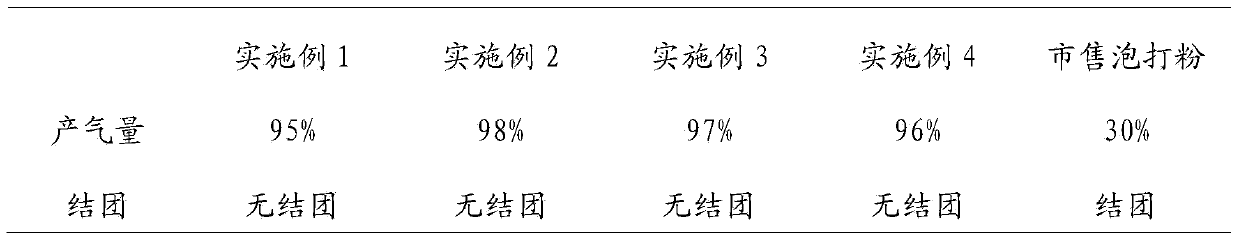

A sour agent and baking powder technology, applied in the fields of application, food preparation, food science, etc., can solve the problems of the quality stability of baking powder products and shorten the shelf life of products, so as to prevent agglomeration and the decline of physical and chemical indicators, and ensure effective production The effect of gas volume and considerable economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

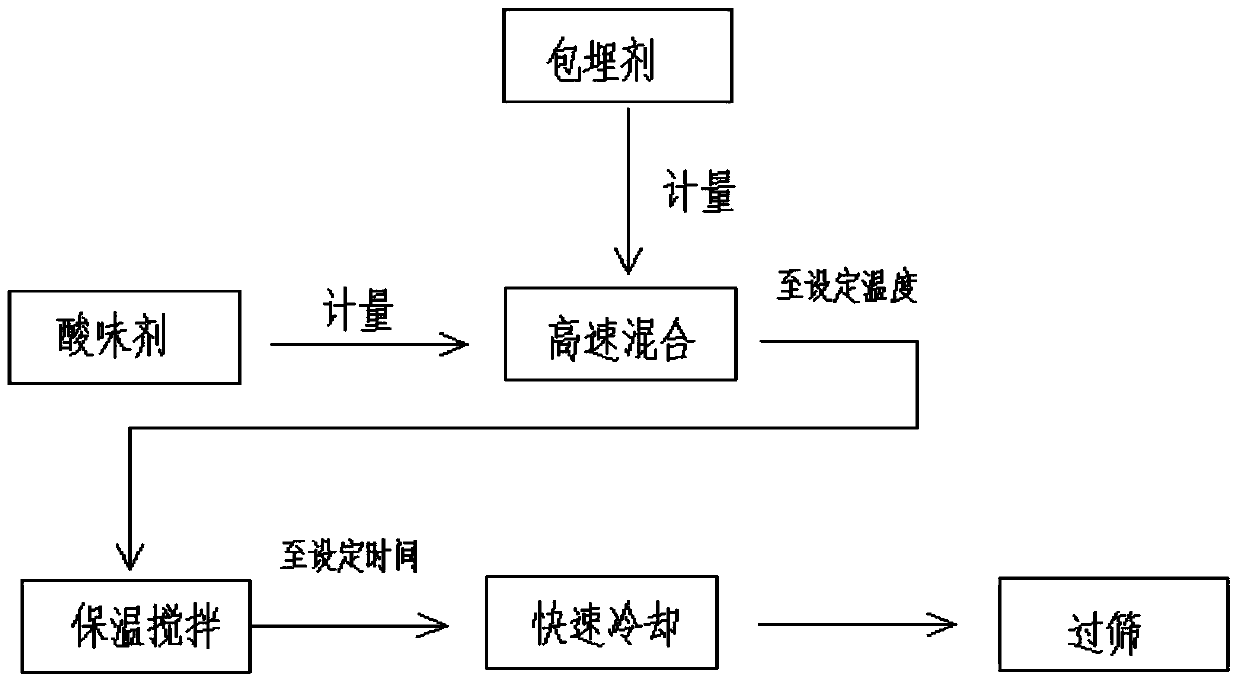

[0030] In this embodiment, the embedding agent is monoglyceride, and the sour agent is potassium alum powder.

[0031] 1. Put the embedding agent and the sour agent into the feeding equipment, and the said feeding equipment is to feed the high-speed mixer according to the weight ratio of the sour agent: embedding agent between 100:0.1;

[0032] 2. The mixed material formed by the embedding agent and the sour agent is embedded in a high-speed mixer, and the temperature of the mixed material is kept at 50°C by adjusting the speed of the mixer, and the embedding is carried out for 10 minutes;

[0033] 3. After the mixed material is automatically discharged by the high-speed mixer, it is cooled and sieved to obtain the embedded sour agent.

Embodiment 2

[0035] In this embodiment, the embedding agent is monoglyceride, and the sour agent is potassium alum powder.

[0036] 1. The embedding agent and the sour agent are put into the feeding equipment, and the said feeding equipment is fed to the high-speed mixer by the sour agent: the weight ratio of the embedding agent is 100:5;

[0037] 2. The mixed material formed by the embedding agent and the sour agent is embedded in a high-speed mixer, and the temperature of the mixed material is kept at 60°C by adjusting the speed of the mixer, and the embedding is carried out for 8 minutes;

[0038] 3. After the mixed material is automatically discharged by the high-speed mixer, it is cooled and sieved to obtain the embedded sour agent.

Embodiment 3

[0040] In this embodiment, the embedding agent is monoglyceride, and the sour agent is ammonium alum powder.

[0041] 1. The embedding agent and the sour agent are put into the feeding equipment, and the said feeding equipment is fed to the high-speed mixer according to the sour agent: the weight ratio of the embedding agent is 100:3;

[0042] 2. The mixed material formed by the embedding agent and the sour agent is embedded in a high-speed mixer, and the temperature of the mixed material is kept at 65°C by adjusting the speed of the mixer, and the embedding is carried out for 5 minutes;

[0043] 3. After the mixed material is automatically discharged by the high-speed mixer, it is cooled and sieved to obtain the embedded sour agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com