Fluxing agent and use method thereof

A technology of flux and mass fraction, applied in the direction of manufacturing converters, etc., can solve the problems such as difficulty in adapting to the demand for dephosphorization of molten steel, poor dephosphorization effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

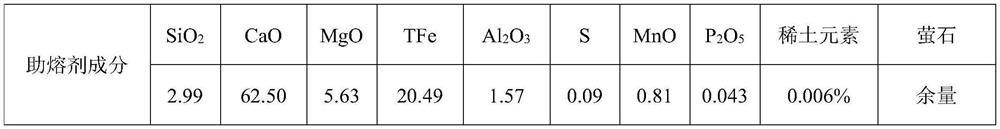

[0037] The composition of flux in the present embodiment is as shown in table 1 below:

[0038] The flux composition of table 1 embodiment 1

[0039]

[0040] The use process of this flux includes the following steps:

[0041] Step 1, when the silicon content in the molten iron is less than 0.5%, the gun position is suitable for high and low. Before and during the converter smelting, the flux is added gradually according to the slag formation; during the whole smelting process, the amount of flux added is 3kg per ton of steel. The specific composition of the slagging material is 8% of dolomite, 10% of bauxite, 75% of lime, 2-4% of crude aluminum,

[0042] Step 2: During the blowing process, add corresponding high-calcium ash and a small amount of flux in batches according to the condition of the slag. When adding the flux, the lance position can be lowered, and after adding the oxygen lance can be raised. When slag is melted, judge according to the flame The oxygen lance...

Embodiment 2

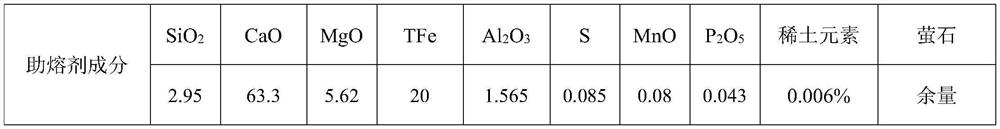

[0063] The flux composition of table 1 embodiment 2

[0064]

[0065] The use process of this flux includes the following steps:

[0066] Step 1, when the silicon content in the molten iron is less than 0.5%, the gun position is suitable for high and low. Before and during the converter smelting, the flux is added gradually according to the slag formation; during the whole smelting process, the amount of flux added is 3kg per ton of steel. The specific composition of the slagging material is 8% of dolomite, 10% of bauxite, 75% of lime, 3% of crude aluminum,

[0067] Step 2: During the blowing process, add corresponding high-calcium ash and a small amount of flux in batches according to the condition of the slag. When adding the flux, the lance position can be lowered, and after adding the oxygen lance can be raised. When slag is melted, judge according to the flame The oxygen lance moves around to reduce the slag back-drying and control the bad phenomenon of splashing. A...

Embodiment 3

[0071] The flux composition of table 1 embodiment 2

[0072]

[0073] The use process of this flux includes the following steps:

[0074] Step 1, when the silicon content in the molten iron is less than 0.5%, the gun position is suitable for high and low. Before and during the converter smelting, the flux is added gradually according to the slag formation; during the whole smelting process, the amount of flux added is 3kg per ton of steel. The specific composition of the slagging material is 5% of dolomite, 13% of bauxite, 65% of lime, 2% of crude aluminum,

[0075] Step 2: During the blowing process, add corresponding high-calcium ash and a small amount of flux in batches according to the condition of the slag. When adding the flux, the lance position can be lowered, and after adding the oxygen lance can be raised. When slag is melted, judge according to the flame The oxygen lance moves around to reduce the slag back-drying and control the bad phenomenon of splashing. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com