Solution for sterilizing and cleaning hemodialysis machine and preparation method of solution

A technology of hemodialysis machine and solution, applied in chemical instruments and methods, botanical equipment and methods, chemicals for biological control, etc., can solve the problems of high production cost, poor stability, etc. Wide range and good product stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

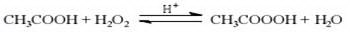

Method used

Image

Examples

Embodiment 1

[0030] First, take 0.01 kg of sodium pyrophosphate, 19.0 kg of glacial acetic acid, and 61.2 kg of reverse osmosis water in a liquid mixing tank, start stirring at room temperature and stir for 30 minutes to obtain an inert substance solution.

[0031] Put 3.5kg of 40% peracetic acid and 17.3kg of 30% hydrogen peroxide into the above-mentioned inert substance liquid mixing tank and stir at 25°C-35°C for 2 hours to obtain a disinfectant mother liquor, which is passed through three stages Type microporous membrane filtration (the pore size of the filter membrane is 1.2μm-0.45μm-0.22μm, and the order of flow through the filter membrane pore size is from large to small) and then filled to obtain the final product.

Embodiment 2

[0033] Take 0.02kg of sodium pyrophosphate, 20.0kg of glacial acetic acid, and 56.0kg of reverse osmosis water in a liquid mixing tank, start stirring at room temperature and stir for 30 minutes to obtain an inert substance solution.

[0034] Put 4.0kg of 40% peracetic acid and 20.0kg of 30% hydrogen peroxide into the above-mentioned liquid mixing tank and stir at 25°C-35°C for 2.5 hours to obtain a disinfectant mother liquor. Pore filter membrane filtration (the pore size of the filter membrane is 1.2μm-0.45μm-0.22μm, and the order of flow through the filter membrane pore size is from large to small) and then filled to obtain the final product.

Embodiment 3

[0036] Take 0.03kg of sodium pyrophosphate, 22.0kg of glacial acetic acid, and 56.0kg of reverse osmosis water in a liquid mixing tank, start stirring at room temperature and stir for 30 minutes to obtain an inert substance solution.

[0037] Put 4.6kg of 40% peracetic acid and 20.0kg of 30% hydrogen peroxide into the above-mentioned liquid mixing tank and stir at 25°C-35°C for 2 hours to obtain a disinfectant mother liquor. Pore filter membrane filtration (the pore size of the filter membrane is 1.2μm-0.45μm-0.22μm, and the order of flow through the filter membrane pore size is from large to small) and then filled to obtain the final product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com