A kind of serum separating gel and preparation method thereof

A serum separation gel and a separation gel technology, which are applied in the field of serum separation gel and its preparation, can solve the problems of difficulty in increasing the specific gravity of products, inaccurate sampling of probes, interference with test results, etc., and achieve mature and perfect production technology and safe production process. The effect of environmental protection and wide product selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Prepare serum-separating gels by:

[0031] S1: quaternary ammonium salt ions and halide ions are prepared into an ionic liquid with a density of 1.2g / ml;

[0032] S2: The 5g hydrophilic fumed silica powder (specific surface area 200m 2 / g, the bulk density is 60kg / m 3 ) and 0.02g hexamethyldisilazane were stirred in a planetary mixer for 3 hours (15r / min), then left to stand for 12 hours to obtain a carrier-silane coupling agent blend;

[0033] S3: Stir 100 g of the ionic liquid and the carrier-silane coupling agent blend in a planetary mixer for 4 hours (40 r / min) to fully disperse the carrier in the ionic liquid to obtain the serum separating gel.

[0034] Preferably, in S2, the carrier-silane coupling agent blend is obtained by stirring the carrier and the silane coupling agent in a mixer for 3 hours, and then standing for 12 hours;

[0035] S4: Vacuum (0.1MPa) to remove air bubbles.

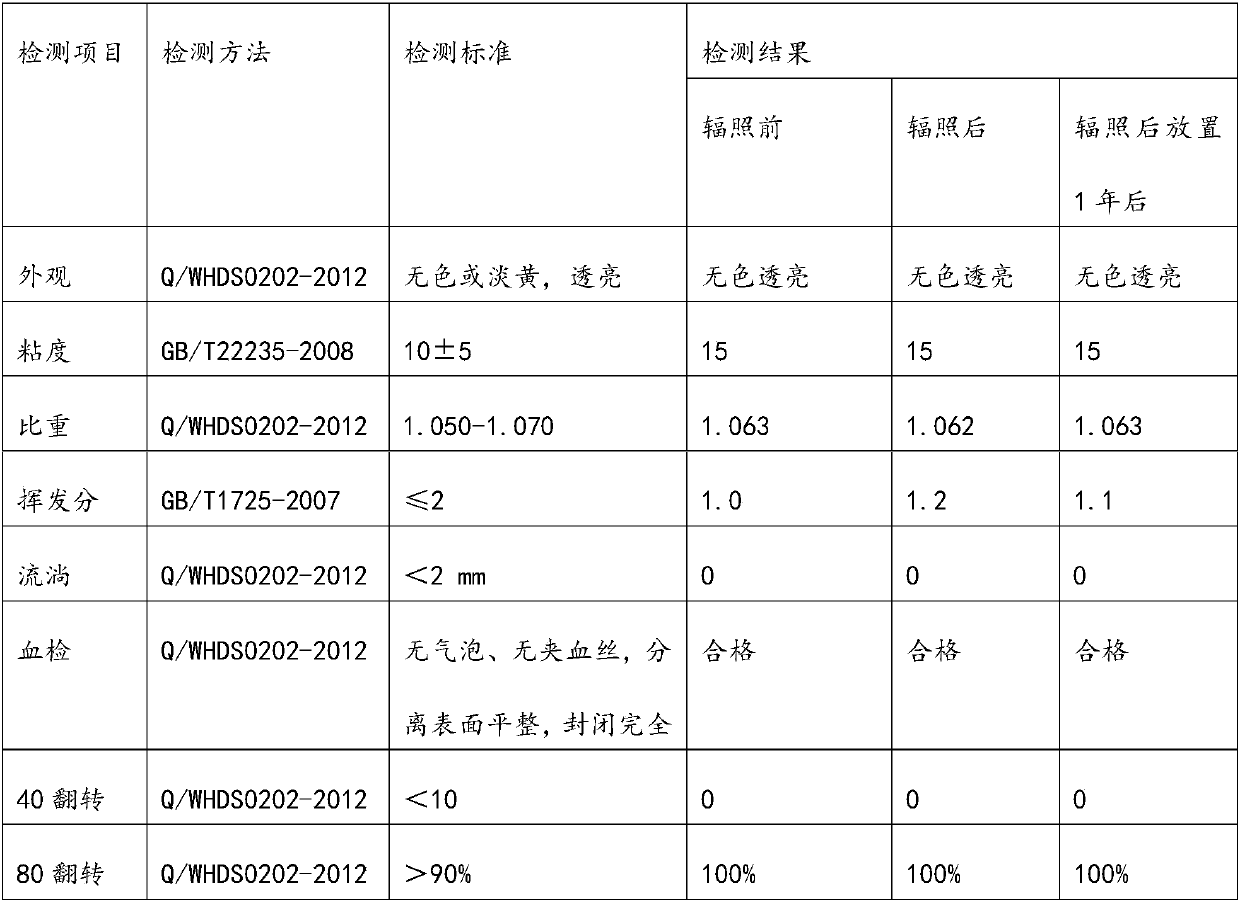

[0036] The product testing results are shown in Table 1:

[0037] The charact...

Embodiment 2

[0041] Prepare serum-separating gels by:

[0042] S1: Pyrrole salt ions and tetrafluoroborate ions were prepared into an ionic liquid with a density of 1.15g / ml;

[0043] S2: The 5g hydrophilic fumed silica powder (specific surface area 240m 2 / g, the bulk density is 80kg / m 3 ) and 0.02g hexamethyldisilazane were stirred in a planetary mixer for 3 hours (15r / min), then left to stand for 12 hours to obtain a carrier-silane coupling agent blend;

[0044] S3: Stir 100 g of the ionic liquid and the carrier-silane coupling agent blend in a planetary mixer for 4 hours (40 r / min) to fully disperse the carrier in the ionic liquid to obtain the serum separating gel.

[0045] Preferably, in S2, the carrier-silane coupling agent blend is obtained by stirring the carrier and the silane coupling agent in a mixer for 3 hours, and then standing for 12 hours;

[0046] S4: Vacuum (0.1MPa) to remove air bubbles.

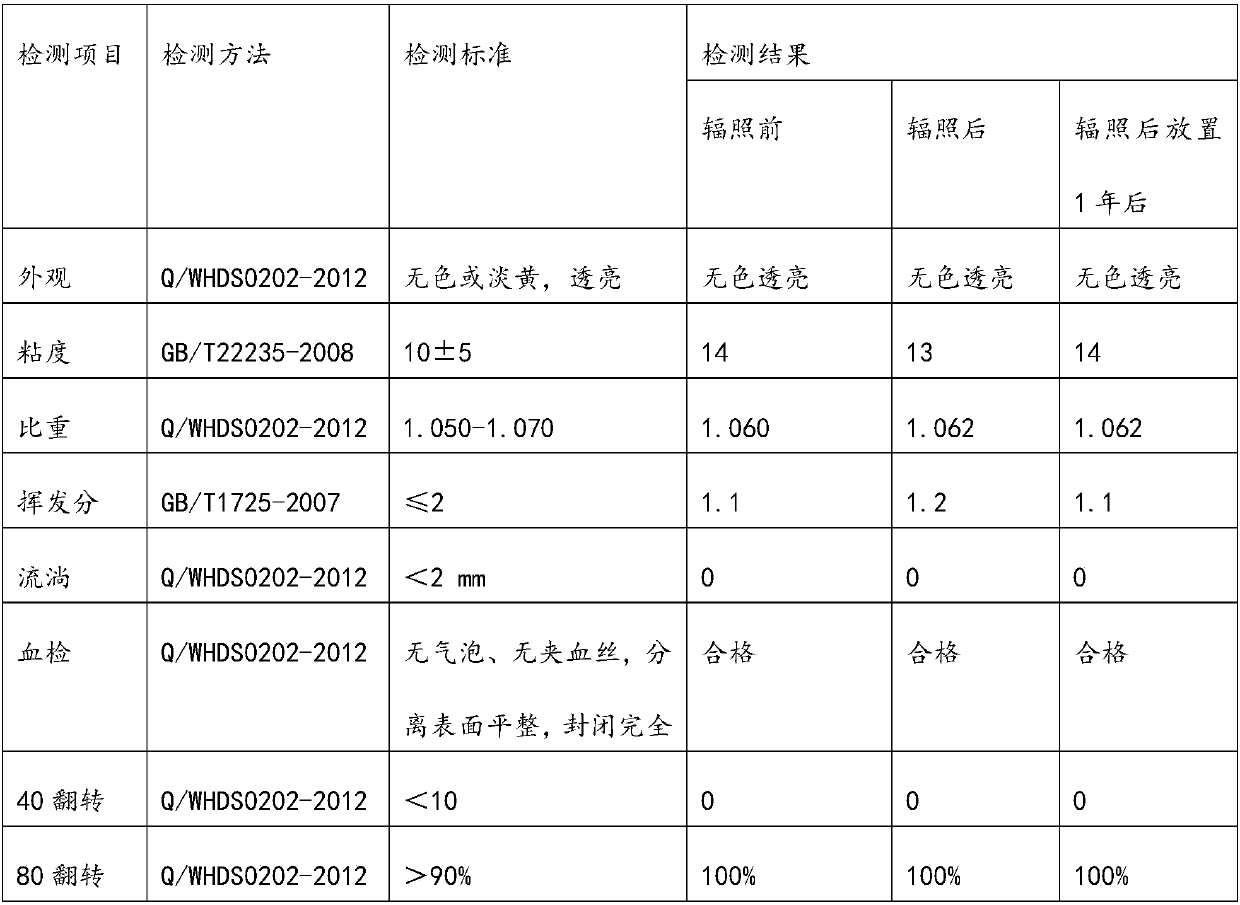

[0047] The product testing results are shown in Table 2:

[0048] The charac...

Embodiment 3

[0052] Prepare serum-separating gels by:

[0053] S1: Preparation of quaternary phosphonium salt ions and halide ions into an ionic liquid with a density of 1.1 g / ml;

[0054] S2: The 6g hydrophilic fumed silica powder (specific surface area 260m 2 / g, the bulk density is 90kg / m 3 ) and 0.05g vinyltrimethoxysilane were stirred in a planetary mixer for 3 hours (15r / min), and then left to stand for 12 hours to obtain a carrier-silane coupling agent blend;

[0055] S3: Stir 100 g of the ionic liquid and the carrier-silane coupling agent blend in a planetary mixer for 4 hours (40 r / min) to fully disperse the carrier in the ionic liquid to obtain the serum separating gel.

[0056] Preferably, in S2, the carrier-silane coupling agent blend is obtained by stirring the carrier and the silane coupling agent in a mixer for 3 hours, and then standing for 12 hours;

[0057] S4: Vacuum (0.1MPa) to remove air bubbles.

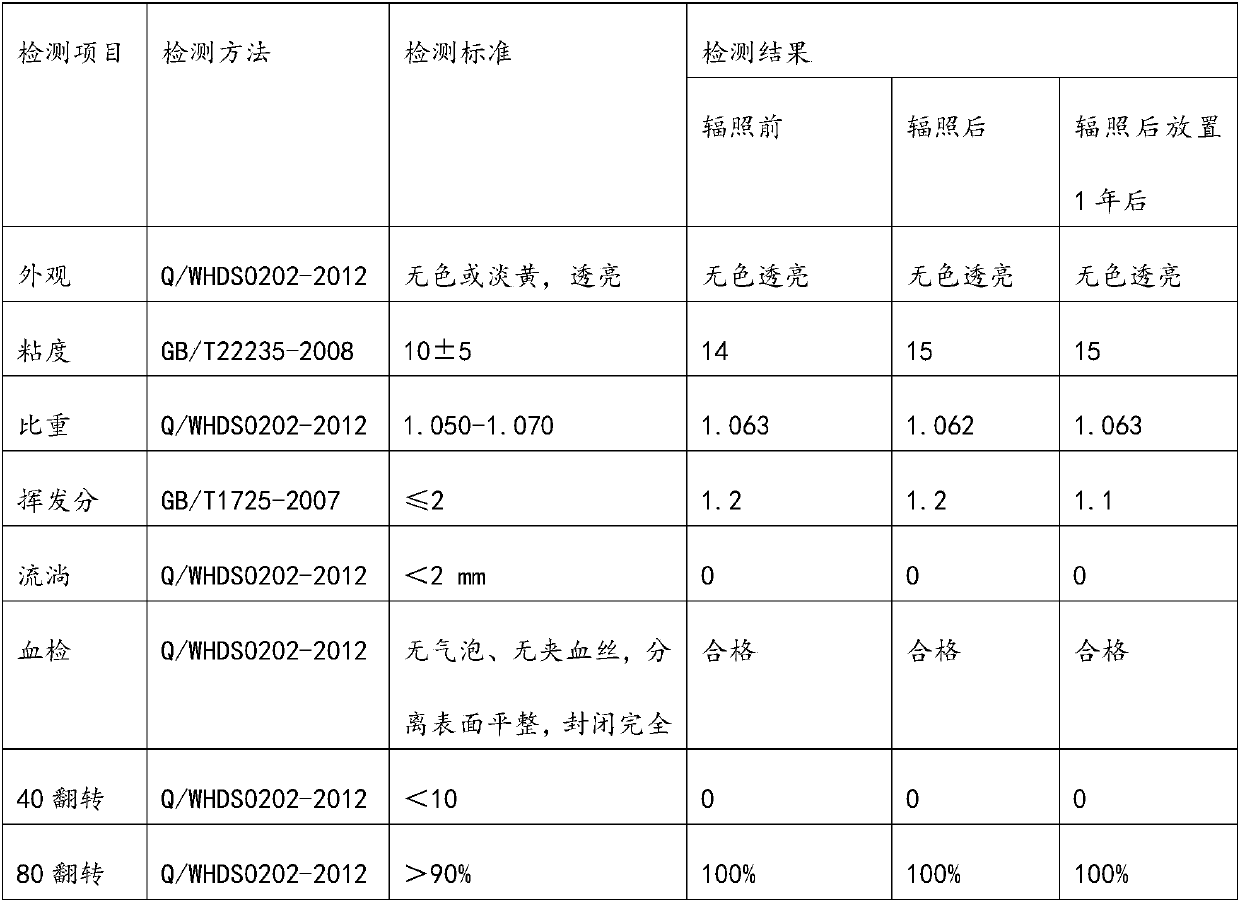

[0058] The product testing results are shown in Table 3:

[0059] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com