Method for melting green silicon carbide from smokeless ultra low-ash pure coal and green silicon carbide prepared therefrom

A technology of ultra-low ash pure coal and green silicon carbide, which is applied in the field of crystal preparation, can solve the problems of green silicon carbide raw material cost rise, furnace spraying, and quality reduction, so as to meet long-term production and use, reduce production costs, and ensure product quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

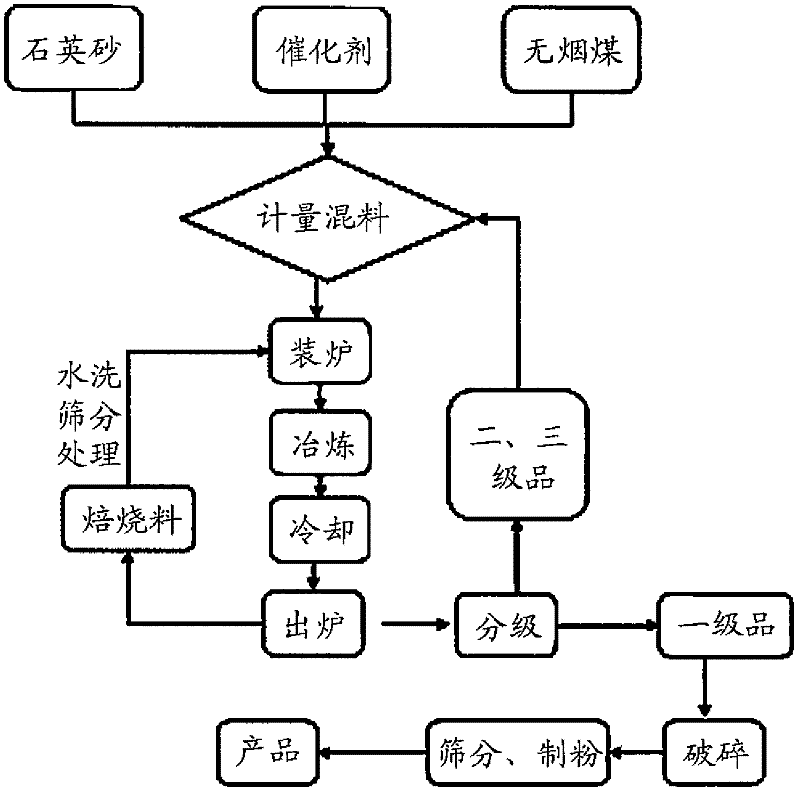

[0032] Preparation Example

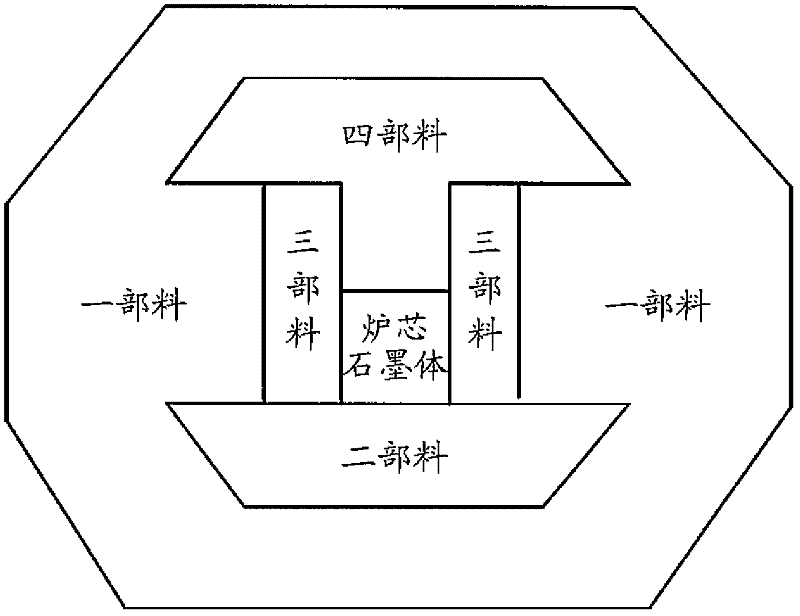

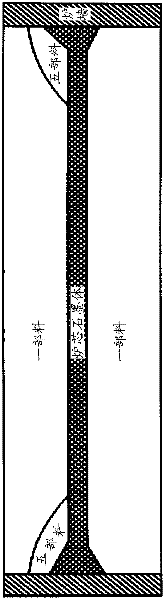

[0033] 1. Ingredients: Weigh various raw materials according to the ingredient list and process regulations and mix them evenly to make the furnace materials required by each furnace position. Smokeless ultra-low ash pure coal physical and chemical indicators: ash 2%, moisture 8%, particle size 0.5-3mm; quartz sand physical and chemical indicators: SiO 2 Content 99%, particle size 1-12mm. One part of the material is the thermal insulation material, which refers to the mixture (including smokeless ultra-low ash pure coal, quartz sand, salt and a small amount of silicon carbide) that has not been completely reacted on the outermost layer after the smelting of the previous furnace of green silicon carbide. , the next furnace is still wrapped in the outer layer for protection during the furnace loading process. The mass ratio of anthracite ultra-low ash pure coal to quartz sand in the secondary material (C:SiO 2 (mass ratio) 0.62, the added amount o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com