Full-automatic concrete board die casting machine

A concrete slab die-casting machine, fully automatic technology, applied in the direction of ceramic molding machines, manufacturing tools, etc., can solve the problems of large differences in the strength of concrete slabs, low automation, uneven material ratios for each pot, etc., and achieve physical and chemical indicators Stable and consistent, stable mechanical properties, uniform product thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

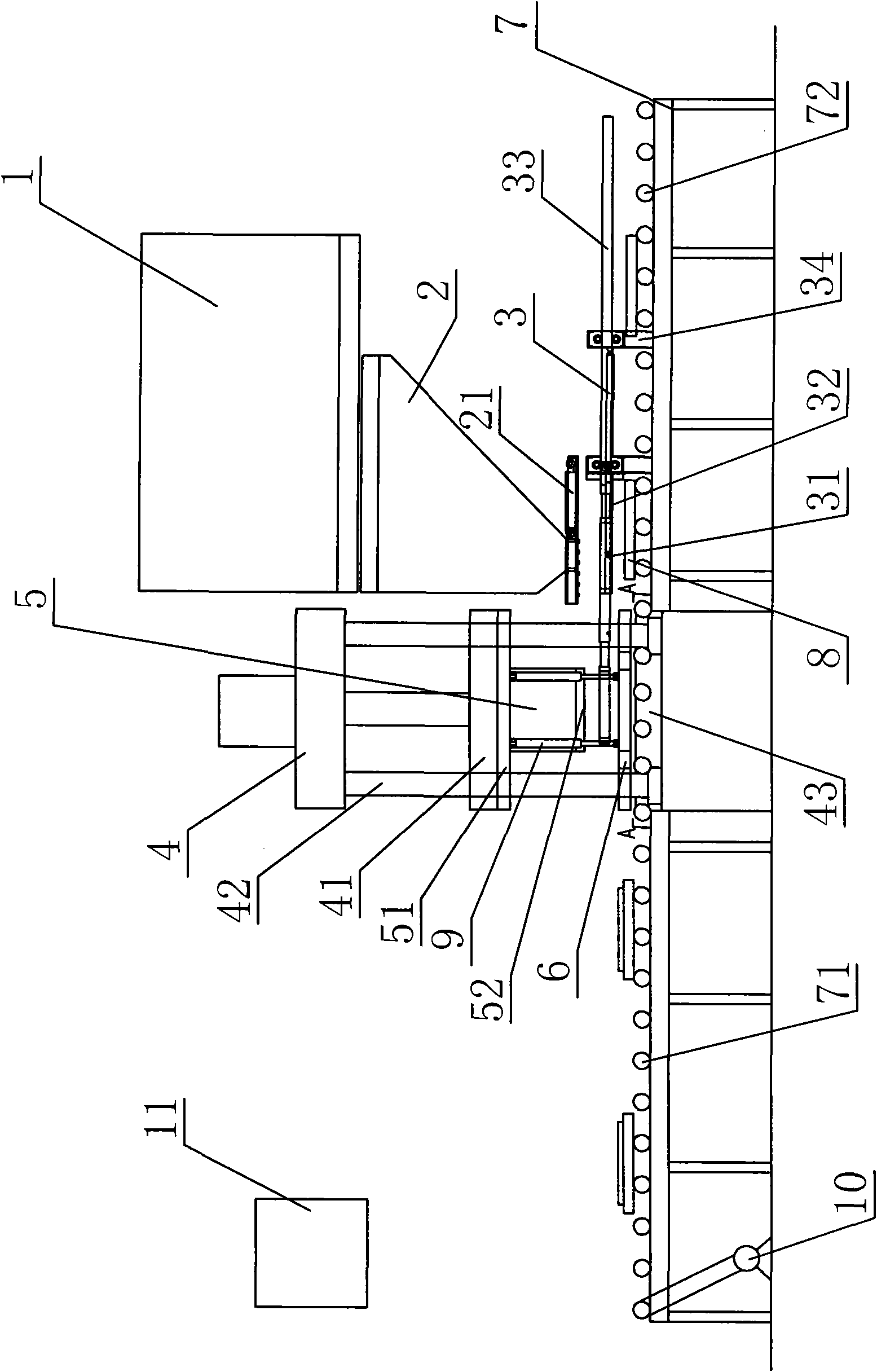

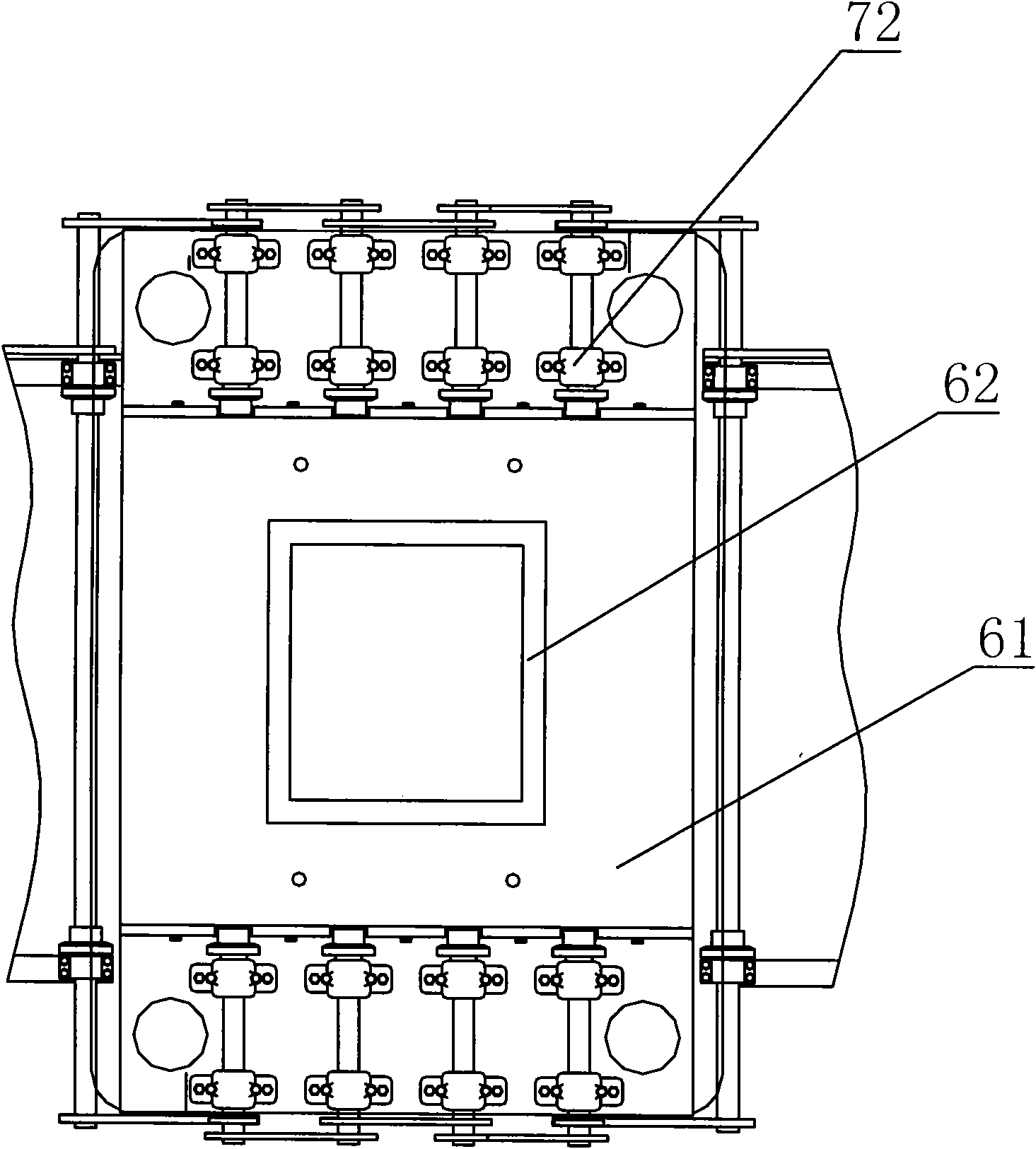

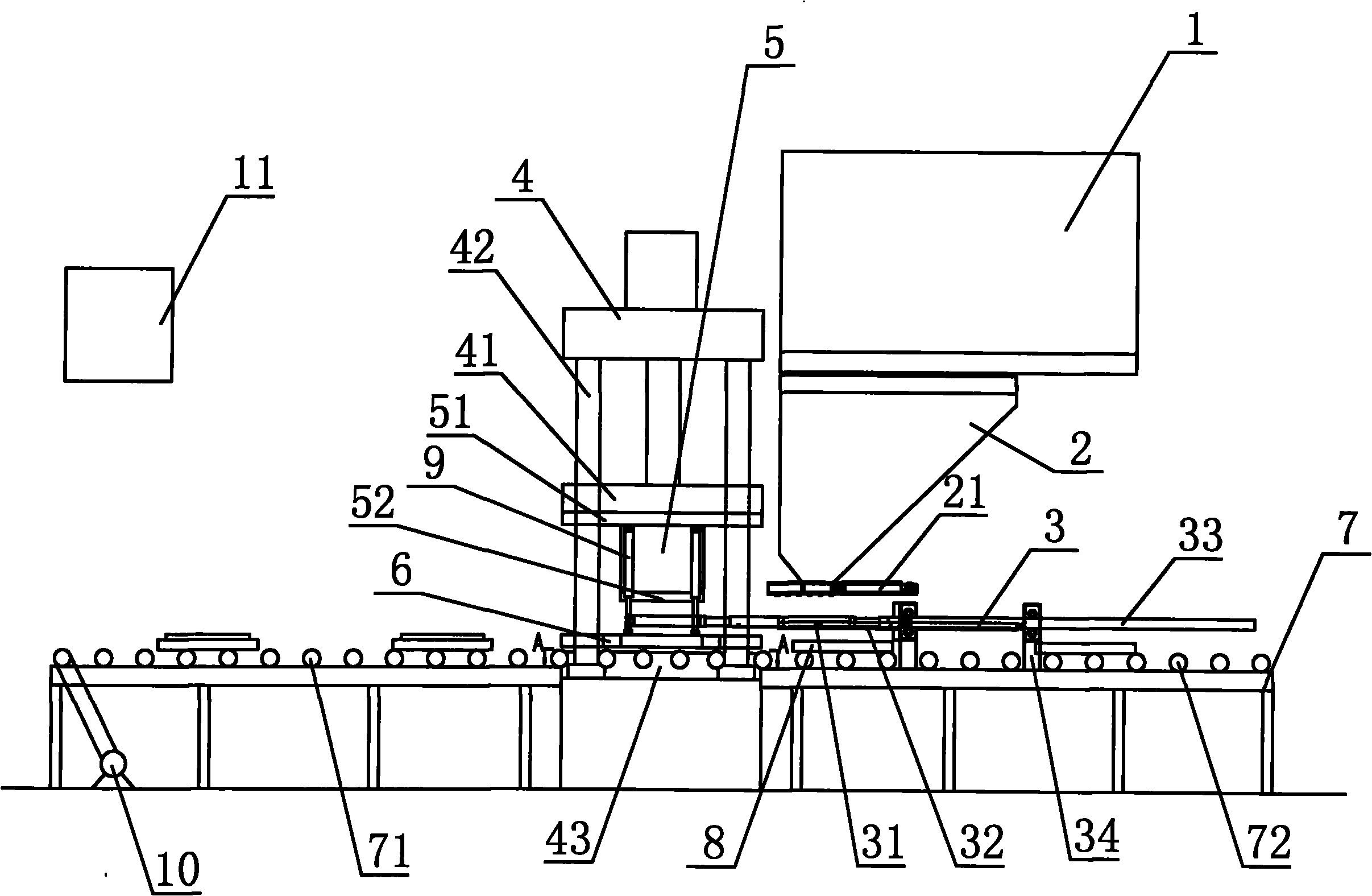

[0020] Please refer to figure 1 and figure 2 as shown, figure 1 It is a structural schematic diagram of the automatic concrete plate die-casting machine of the present invention; figure 2 It is a structural schematic diagram of the female mold of the automatic concrete slab die-casting machine of the present invention.

[0021] In this embodiment, a fully automatic concrete plate die-casting machine includes a mixer 1, a hopper 2, a batching mechanism 3, a press 4, a male mold 5, a female mold 6, a conveying mechanism 7, a tray 8, and a hydraulic cylinder 9 , a driving device 10 and a hydraulic electrical system 11, the mixer 1 has a weighing and measuring function, and can accurately control the amount of materials used for each mixing, and a hopper 2 is fixed below the mixer 1, and the hopper 2 is provided with a feed control valve 21, on the one hand, the mixed material that has been stirred can be put into the hopper 2 at one time for standby, so that the mixer 1 can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com