Preparation method of NCA precursor

A precursor and solid technology, applied in the field of preparation of NCA precursors, can solve the problems of uneven aluminum content inside and outside the nickel cobalt aluminum hydroxide, affecting quality stability and production efficiency, and large fluctuations in density and morphology. Achieve the effect of good electrochemical performance, stable content and stable physical and chemical indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

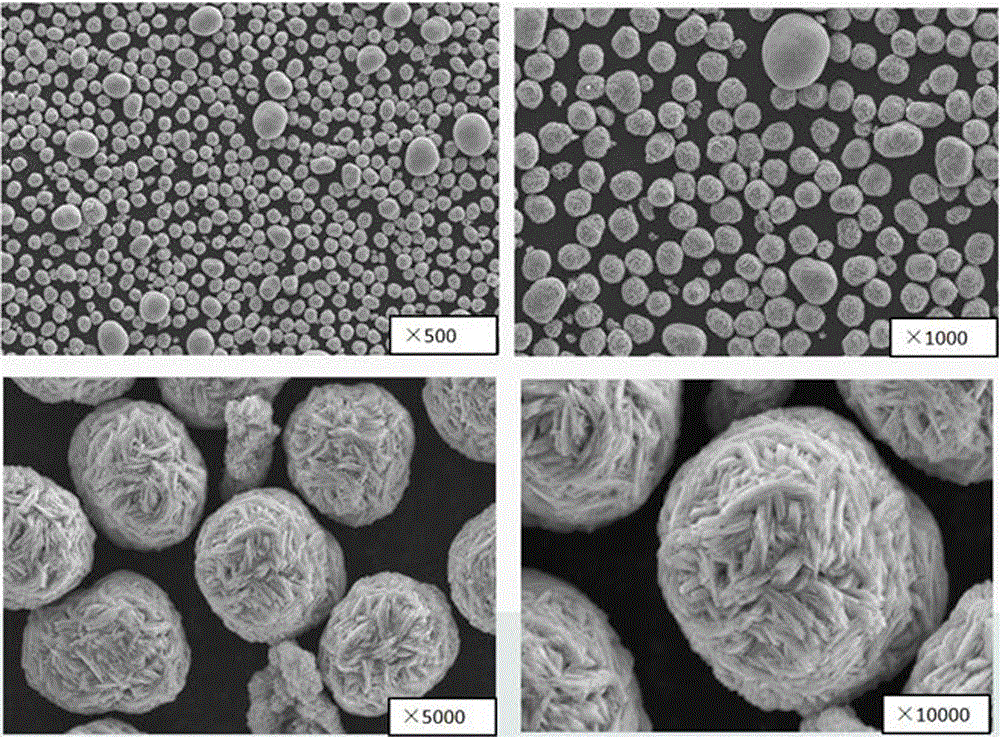

Image

Examples

Embodiment 1

[0020] The invention provides a kind of preparation method of NCA precursor, and this method comprises the steps:

[0021] (1) Mix the water-soluble salt of Ni and the water-soluble salt of Co and prepare an aqueous solution to obtain a mixed ion solution, wherein the mixed ion solution includes Ni 2+ and Co 2+ The mixed ion concentration is 1.5mol / L;

[0022] (2) Prepare mixed alkali solution Ⅰ, first prepare sodium hydroxide solution with a concentration of 3.0mol / L, then add a certain amount of solid aluminum sulfate, the concentration is 0.2mol / L, after it is completely dissolved, add ammonia water, the concentration is 0.1mol / L, so far the configuration of the mixed alkali solution I is completed;

[0023] (3) Prepare the mixed alkali solution II. First prepare a sodium hydroxide solution with a concentration of 3.0mol / L, then add a certain amount of solid aluminum sulfate with a concentration of 0.3mol / L. After it is completely dissolved, add ammonia water with a conc...

Embodiment 2

[0027] The invention provides a kind of preparation method of NCA precursor, and this method comprises the steps:

[0028] (1) Mix the water-soluble salt of Ni and the water-soluble salt of Co and prepare an aqueous solution to obtain a mixed ion solution; wherein the mixed ion solution includes Ni 2+ and Co 2+ The concentration of mixed ions is in the range of 1.0mol / L;

[0029] (2) Prepare mixed alkali solution I, first prepare sodium hydroxide solution with a concentration of 2mol / L, then add a certain amount of solid aluminum sulfate, the concentration is 0.3mol / L, after it is completely dissolved, add ammonia water, the concentration is 0.3mol / L L, so far the configuration of the mixed alkali solution I is completed;

[0030] (3) Prepare mixed alkali solution II, first prepare sodium hydroxide solution with a concentration of 2.0mol / L, then add a certain amount of solid aluminum sulfate with a concentration of 0.4mol / L, after it is completely dissolved, add ammonia wate...

Embodiment 3

[0034] The invention provides a kind of preparation method of NCA precursor, and this method comprises the steps:

[0035] (1) Mix the water-soluble salt of Ni and the water-soluble salt of Co and prepare an aqueous solution to obtain a mixed ion solution; wherein the mixed ion solution includes Ni 2+ and Co 2+ The concentration of mixed ions is in the range of 1.5mol / L;

[0036] (2) Prepare mixed alkali solution Ⅰ, first prepare sodium hydroxide solution with a concentration of 3.0mol / L, then add a certain amount of solid aluminum sulfate, the concentration is 0.25mol / L, after it is completely dissolved, add ammonia water, the concentration is 0.25mol / L, so far the configuration of the mixed alkali solution I is completed;

[0037] (3) Prepare the mixed alkali solution II. First prepare a sodium hydroxide solution with a concentration of 3.0mol / L, then add a certain amount of solid aluminum sulfate with a concentration of 0.4mol / L. After it is completely dissolved, add amm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com