Novel scraper conveyor

A scraper conveyor, a new type of technology, applied in the field of conveying equipment and new scraper conveyors, can solve the problems of increased production cost, decreased dust removal effect, blockage of main pipelines, etc. Consistent, high dust removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

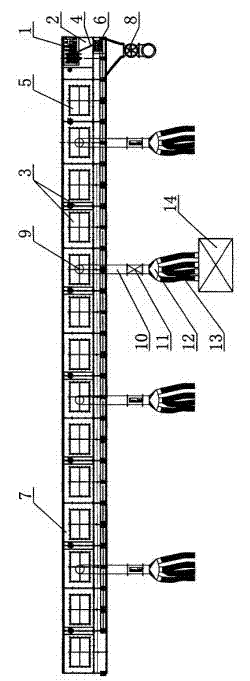

[0019] As shown in the drawings, a new type of scraper conveyor includes an organic head 2, an organic body 3, a chain 4 and a scraper 5, and a transmission device 6. The machine head 2 is provided with a power 1 and an unloader 8 . The fuselage 3 includes an organic tank housing 7 , and the scraper 5 is arranged in the tank housing 7 . The power 1 is connected with the chain 4 through the transmission device 6, and the scraper 5 is fixed on the chain 4. A plurality of air outlets 9 are opened on the machine tank housing 7, and branch pipes 10 are connected to the air outlets 9.

[0020] The branch pipe 10 is provided with a pneumatic valve 11, and the front end of the branch pipe 10 is equipped with a tuyere 12. The air nozzle 12 is connected with a dust suction hose 13 . The setting of pneumatic valve 11 can control the opening and closing of branch pipe 10 conveniently.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com