High-strength hot rolled steel plate with excellent cold forming property and preparation method thereof

A hot-rolled steel sheet and cold-forming technology, applied in metal rolling, metal rolling, rolling mill control devices, etc., can solve the problems of reduced formability, difficulty in meeting forming requirements, high production cost, etc., and achieve lightweight design and manufacturing. , The effect of high shape and dimension accuracy and low residual stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

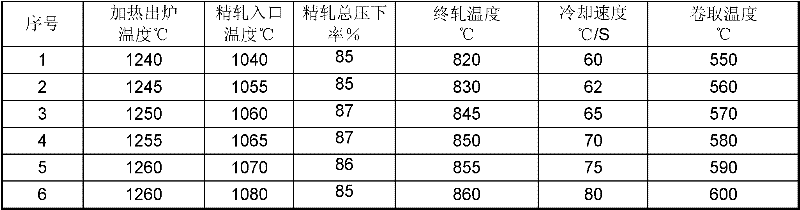

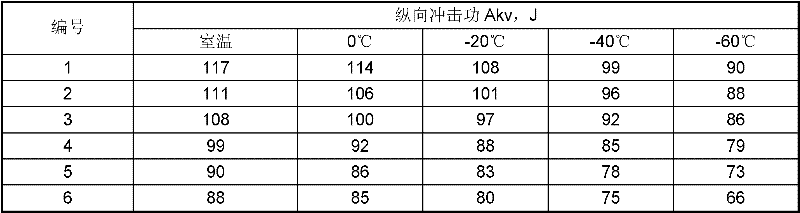

[0022] The present invention is described in detail below with 6 embodiments. The chemical composition steel shown in Table 1 is used as the raw material, and the continuous casting slab size is 230mm. The cast slab is heated by a heating furnace, and then rolled, cooled and coiled by a 2250mm hot continuous rolling mill. Control the furnace temperature, finish rolling entrance temperature, finish rolling total reduction, finish rolling temperature, laminar cooling rate and coiling temperature. The rolling thickness is 5.0mm-10mm. The rolling and cooling process are shown in Table 2, and the mechanical properties are shown in Table 3. The series of temperature longitudinal impact energy are shown in Table 4.

[0023] Table 1 embodiment chemical composition (weight percent %)

[0024] serial number

C

Si

mn

P

S

Al

Nb

Ti

Mo

1

0.04

0.30

1.90

0.010

0.0007

0.020

0.060

0.090

0.0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com