Method for producing titanium-microalloyed steel based on completely endless thin-slab continuous casting and continuous rolling process

A technology of thin slab continuous casting and micro-alloy steel, which is applied in the direction of metal rolling, can solve the problems of high energy consumption and high cost, and achieve the effects of energy saving, low cost and short production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

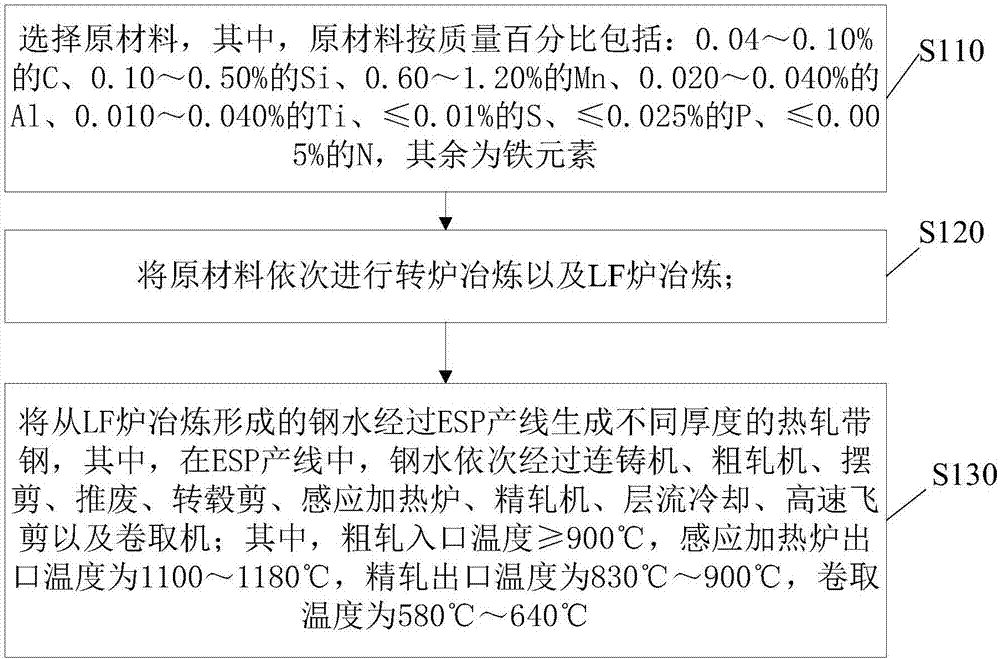

[0045] Select raw materials, wherein the raw materials include: 0.04% C, 0.15% Si, 0.93% Mn, 0.008% S, 0.012% P, 0.025% Al, 0.016% Ti, 0.004% N by mass percentage, and the rest are iron element;

[0046] The raw materials are smelted in converter and LF furnace in turn;

[0047] The continuous casting is produced at a constant casting speed of 5.4m / min, and the hot-rolled strip steel with a thickness of 1.8mm is produced through the all-endless thin slab continuous casting and rolling production line. 1150°C, finish rolling outlet temperature 845°C, coiling temperature 630°C, the coiler is rolled into the warehouse;

[0048] The mechanical properties of the generated titanium micro-alloyed steel are: the yield strength is 414MPa, the tensile strength is 504MPa, and the elongation is 30%.

Embodiment 2

[0050] Select raw materials, wherein the raw materials include: 0.05% C, 0.25% Si, 1.0% Mn, 0.006% S, 0.013% P, 0.020% Al, 0.025% Ti, 0.003% N, and the rest are iron element;

[0051] The raw materials are smelted in converter and LF furnace in turn;

[0052] The continuous casting is produced at a constant casting speed of 5.0m / min, and the hot-rolled strip steel with a thickness of 1.5mm is produced through the all-endless thin slab continuous casting and rolling production line. The rough rolling inlet temperature is 915°C, and the induction heating furnace outlet temperature 1155°C, finish rolling exit temperature is 850°C, coiling temperature is 600°C, the coiler is coiled into the warehouse;

[0053] The mechanical properties of the generated titanium microalloy steel are: the yield strength is 430MPa, the tensile strength is 519MPa, and the elongation is 32%.

Embodiment 3

[0055] Select raw materials, wherein the raw materials include: 0.055% C, 0.30% Si, 1.10% Mn, 0.008% S, 0.014% P, 0.025% Al, 0.030% Ti, 0.004% N by mass percentage, and the rest are iron element;

[0056] The raw materials are smelted in converter and LF furnace in turn;

[0057] The continuous casting is produced at a constant casting speed of 5.5m / min, and the hot-rolled strip steel with a thickness of 2.0mm is produced through the all-endless thin slab continuous casting and rolling production line. The rough rolling inlet temperature is 925°C, and the induction heating furnace outlet temperature is 1150°C, finish rolling exit temperature is 845°C, coiling temperature is 620°C, the coiler is rolled into the warehouse;

[0058] The mechanical properties of the generated titanium microalloy steel are: the yield strength is 436MPa, the tensile strength is 527MPa, and the elongation is 27.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com