Thin-gauge and high-strength hot-rolled steel strip for cold forming and production method of thin-gauge and high-strength hot-rolled steel strip

A production method and high-strength technology, applied in the field of hot-rolled steel strip, can solve the problems of very strict smelting process requirements and difficult control of plate shape and coil shape.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described in detail below in conjunction with specific examples.

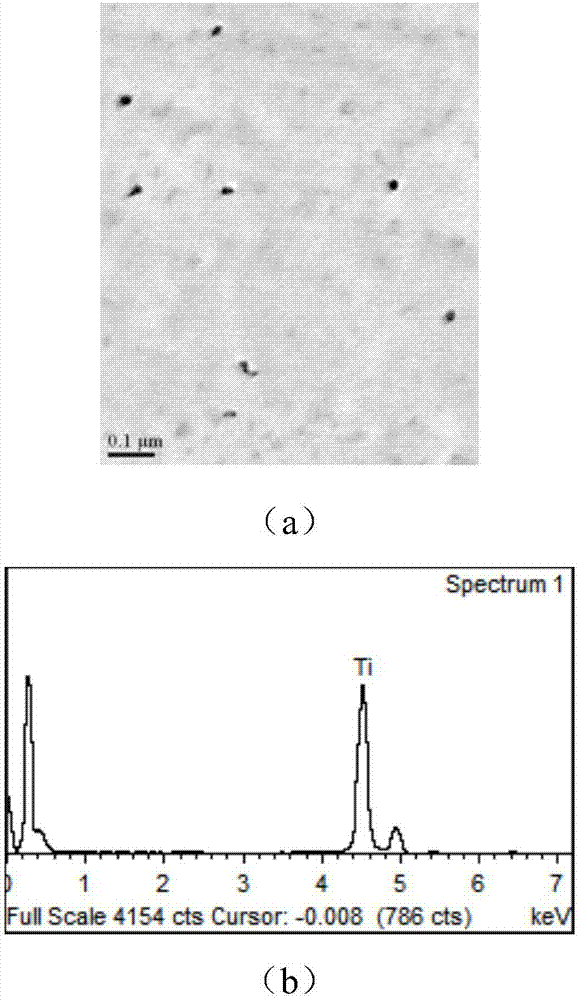

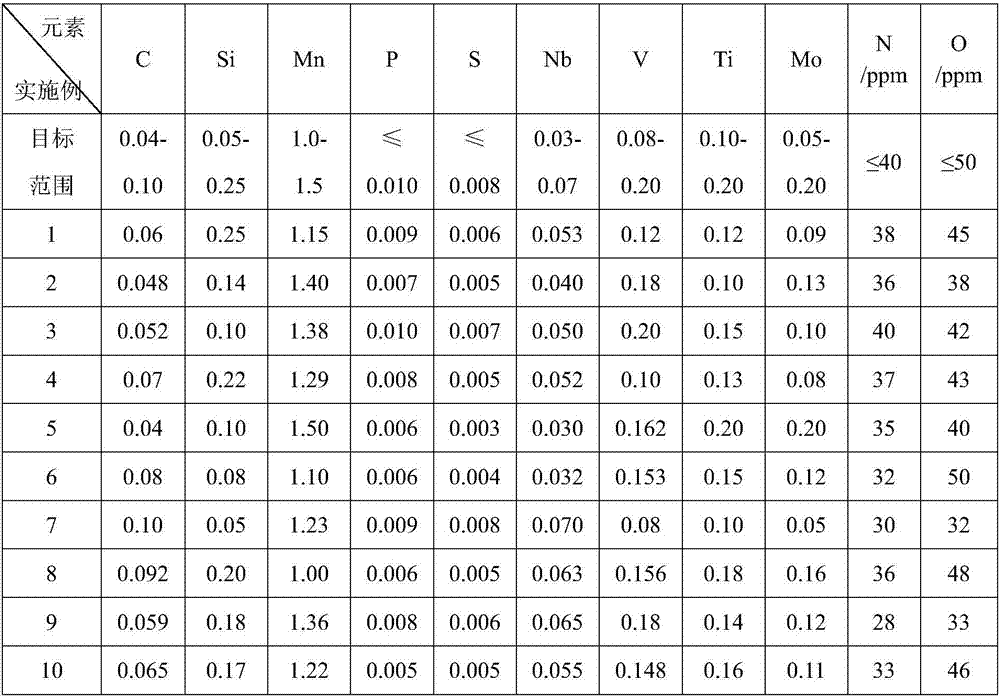

[0051] The thin-gauge high-strength hot-rolled steel strip for cold forming provided by the present invention has the following chemical composition weight contents: C: 0.04-0.10%, Si: 0.05-0.25%, Mn: 1.0-1.5%, P≤0.010%, S≤0.008%, Nb: 0.03~0.07%, V: 0.08~0.20%, Ti: 0.10~0.20%, Mo: 0.05~0.20%, N≤40ppm, O≤50ppm, the balance is Fe and unavoidable impurities . The specific values of the chemical components in each embodiment are shown in Table 1.

[0052] The chemical composition (wt.%) of each embodiment steel strip of table 1

[0053]

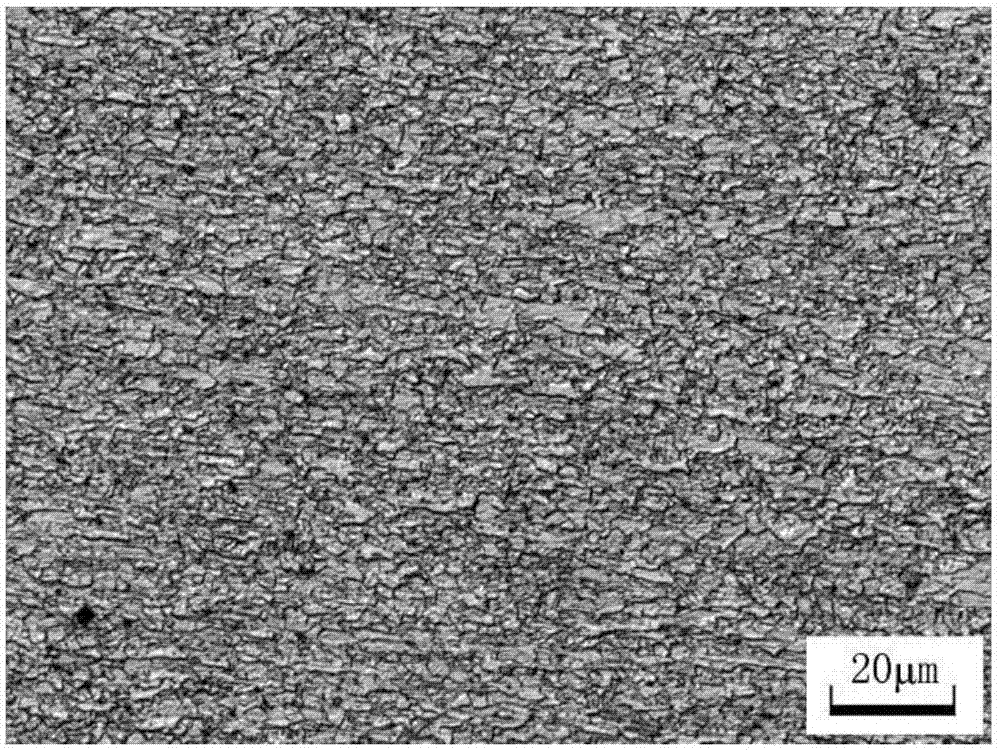

[0054] The production process of the hot-rolled high-strength steel strip includes: blast furnace molten iron→desulfurization of molten iron→converter top-bottom composite blowing→argon blowing→ladle furnace→vacuum treatment→continuous casting→slab inspection→stacking slow cooling→slab heating →Controlled rolling→Controlled cool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com