Ti-Al-Zr-Mo-V system medium-strength high-plasticity titanium alloy and preparation method thereof

A ti-al-zr-mo-v, titanium alloy technology, applied in the field of Ti-Al-Zr-Mo-V series medium-strength high-plastic titanium alloy and its preparation, can solve the problem of poor uniform plastic deformation ability and dimensional accuracy Difficult to control, difficult plastic processing and forming, etc., to achieve the effect of good strength and plasticity, favorable deformation and increased plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

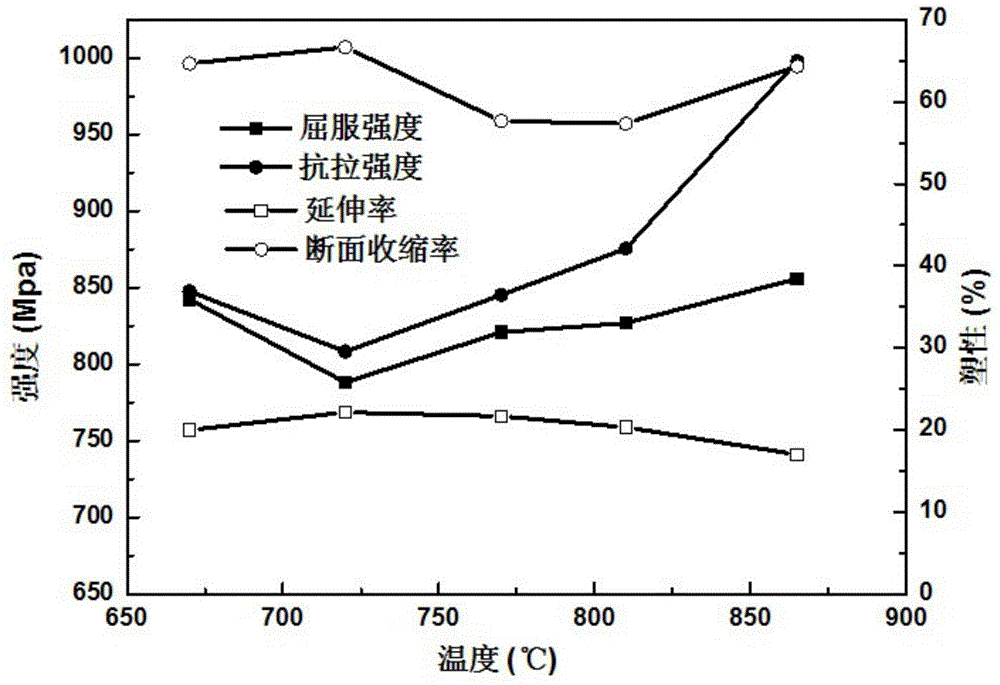

[0032] According to the following formula: Al4.96wt%, Zr2.01wt%, Mo3.05wt%, V1.96wt%, the balance is Ti and unavoidable impurities, prepare electrodes, carry out 3 times of vacuum consumable smelting to obtain ingots, measure The phase transition point of the obtained alloy is 915°C. After the forging is completed, the forgings are sampled, held at 875°C, 825°C, 770°C, 720°C, and 670°C for 1 hour, then air-cooled, and then processed into experimental samples for tensile performance testing. Tensile properties at different heat treatment temperatures figure 1 It can be seen from the figure that the strength and plasticity of the alloy after heat treatment can reach the design target. Select 0.01s -1 ,0.1s -1 ,1s -1 ,10s -1 ,20s -1 These five sets of strain rates were subjected to room temperature compression tests on the Gleeble testing machine, and the room temperature strain rate sensitivity index m was measured as shown in Table 1, and its m value was significantly grea...

Embodiment 2

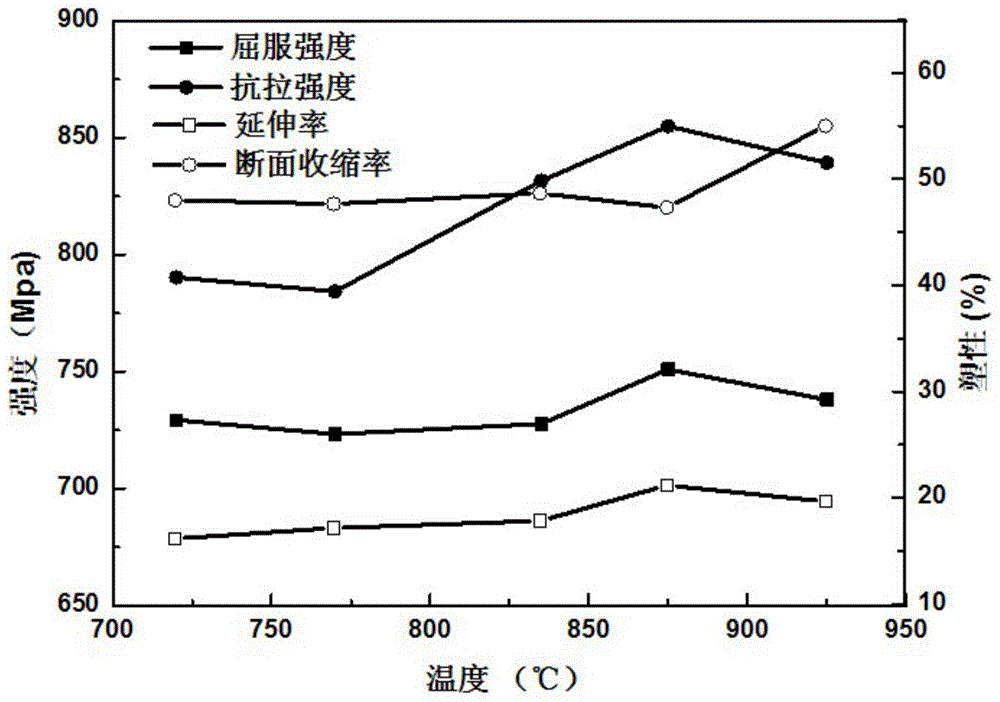

[0034] According to the following formula: Al4.98wt%, Zr0.98wt%, Mo2.03wt%, V1.02wt%, the balance is Ti and unavoidable impurities, prepare electrodes, carry out 3 times of vacuum consumable smelting to obtain ingots, measure The phase transition point of the obtained alloy is 955°C. After the forging is completed, the forgings are sampled, held at 925°C, 875°C, 835°C, 770°C, and 720°C for 1 hour, then air-cooled, and then processed into experimental samples for tensile performance testing. Tensile properties at different heat treatment temperatures figure 2 It can be seen from the figure that the strength and plasticity of the alloy after heat treatment can reach the design target. Select 0.01s -1 ,0.1s -1 ,1s -1 ,10s -1 ,20s -1 These five sets of strain rates were subjected to room temperature compression tests on the Gleeble testing machine, and the room temperature strain rate sensitivity index m was measured as shown in Table 1, and its m value was significantly gre...

Embodiment 3

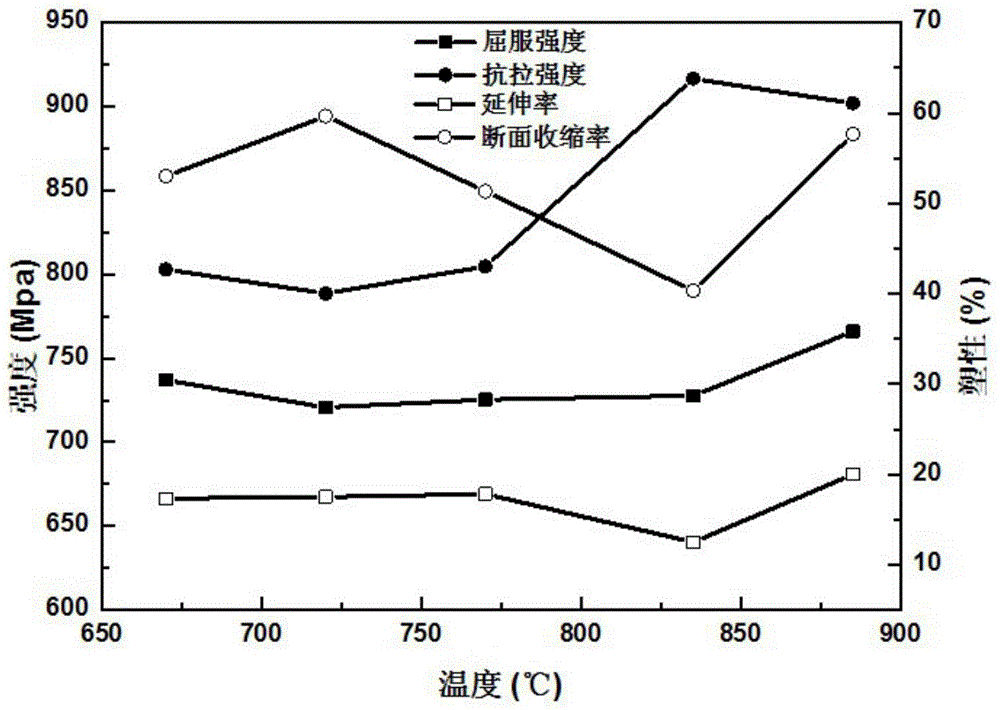

[0036] According to the following formula: Al4.08wt%, Zr2.96wt%, Mo3.13wt%, V1.08wt%, the balance is Ti and unavoidable impurities, prepare electrodes, carry out 3 times of vacuum consumable smelting to obtain ingots, measure The phase transition point of the obtained alloy is 915°C. After the forging is completed, the forgings are sampled, held at 885°C, 835°C, 770°C, 720°C, and 670°C for 1 hour, then air-cooled, and then processed into experimental samples for tensile performance testing. Tensile properties at different annealing temperatures as image 3 It can be seen from the figure that the strength and plasticity of the alloy after heat treatment can reach the design target. Select 0.01s -1 ,0.1s -1 ,1s -1 ,10s -1 ,20s -1 These five sets of strain rates were subjected to room temperature compression tests on the Gleeble testing machine, and the room temperature strain rate sensitivity index m was measured as shown in Table 1, and its m value was significantly greate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com