Weathering resistant steel for low-cost 550MPa hot rolling container and manufacturing method thereof

A manufacturing method and container technology, applied in the field of high-strength steel production, can solve the problems of high steel cost, and achieve the effects of low cost, good corrosion resistance, and easy production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

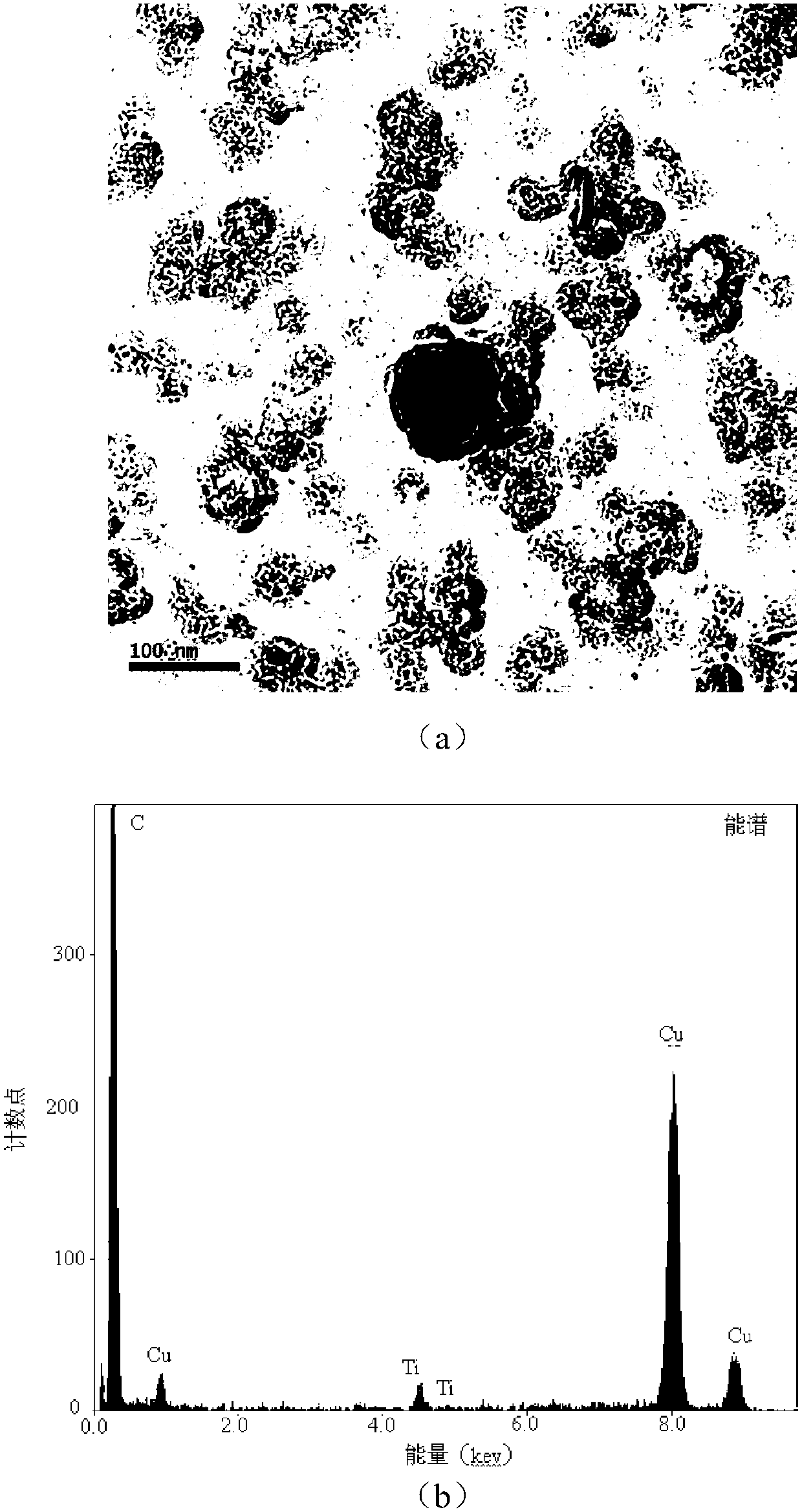

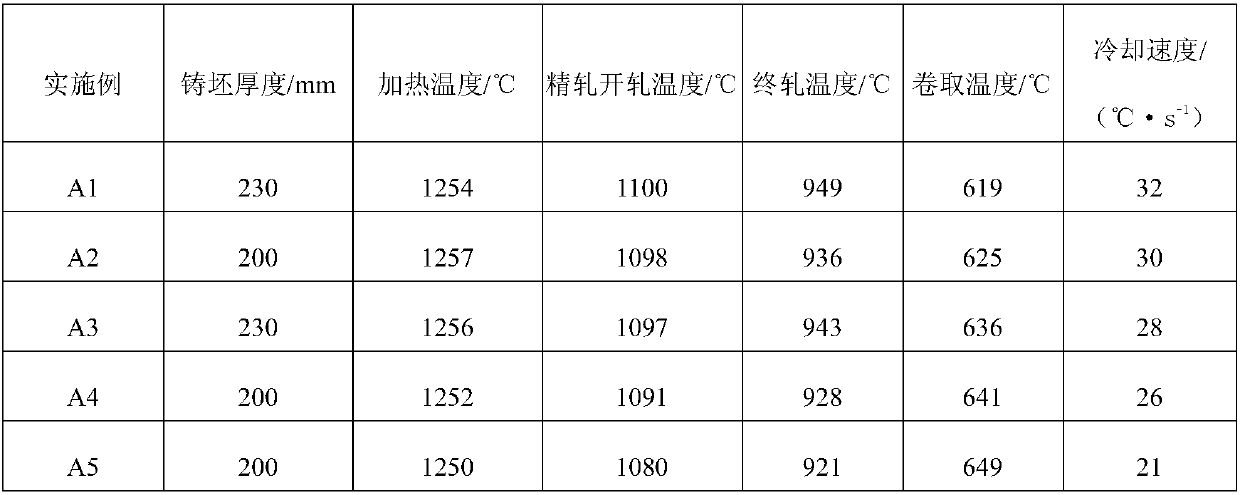

[0030] The technical problems involved in the present invention are solved by the following technical solutions: a low-cost 550MPa grade hot-rolled weathering steel for containers and its manufacturing method, the mass percentage of its chemical composition is: C 0.049%~0.069%, Si 0.20%~0.30% , Mn 0.51%~0.79%, P≤0.020%, S≤0.006%, Als 0.015%~0.045%, Cr 0.31%~0.41%, Ni0.079%~0.099%, Cu 0.21%~0.29%, Ti 0.057% ~0.077%, N≤0.006%, the rest is Fe and unavoidable impurities. It is smelted in a converter, then refined outside the furnace, and cast to obtain a continuous casting slab. The thickness of the continuous casting slab is 200~230mm, and the continuous casting slab is sent to the hot rolling production line. Flow cooling, the cooling speed is greater than 20°C / s, and the coiling temperature is 619-649°C. After coiling, it enters the slow cooling hood for slow cooling. Thickness ≤ 2.0mm, needs to be leveled.

[0031] The following examples are used to specifically illustrate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com