High-strength and high-rigidity structural steel for automobile frame and production method thereof

A production method and high-strength technology, which is applied in high-strength and high-rigidity structural steel for automobile frames and its production field, can solve the problems that cannot fully meet the needs of practical applications, reduce material stiffness, and reduce stiffness, so as to improve welding performance and processing Moldability, reduction of coarse grain size, effect of carbon equivalent reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

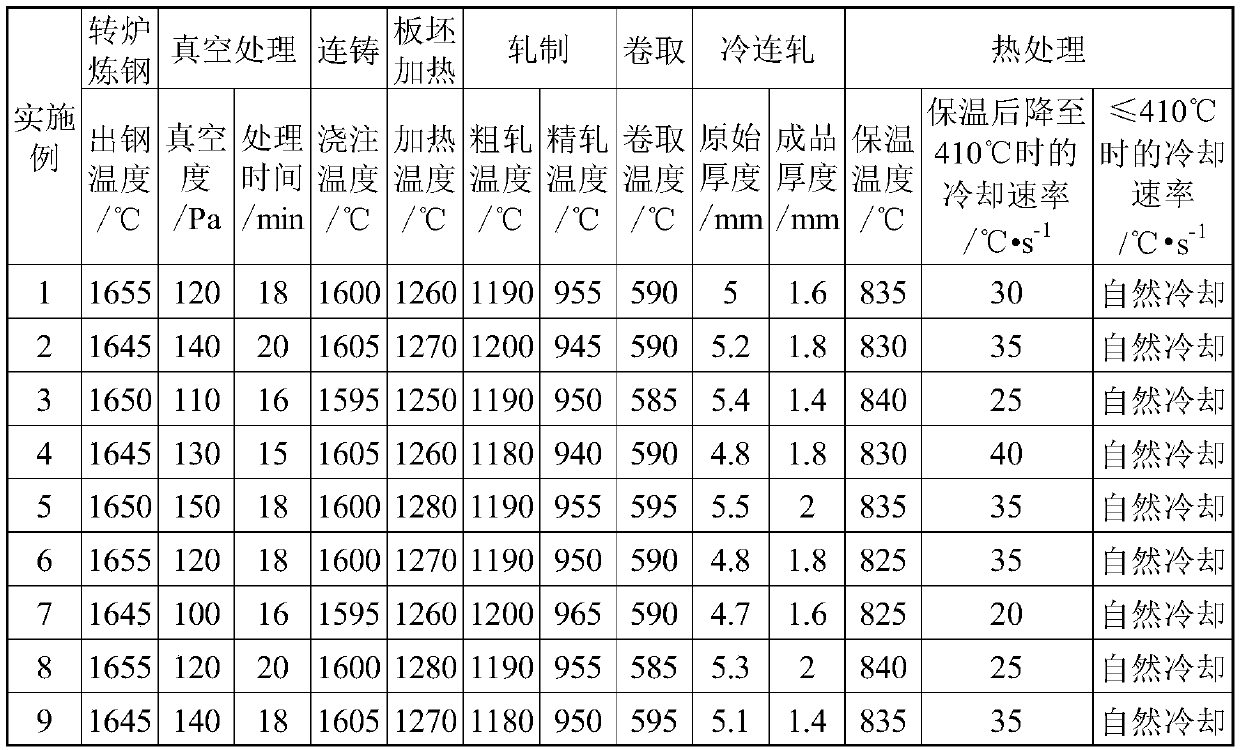

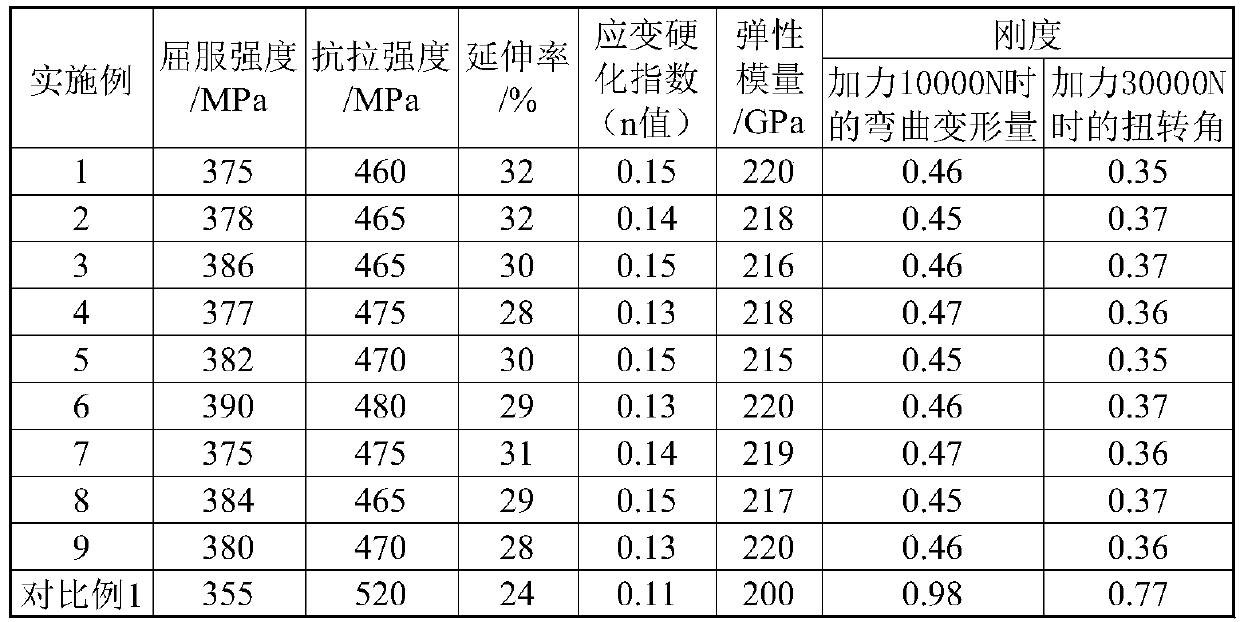

[0028] The present invention will be further described below in conjunction with specific examples.

[0029] The mass percentage distribution of chemical elements in the steels of Examples 1-9 of the present invention and Comparative Example 1 is shown in Table 1, and the balance is Fe and unavoidable impurities.

[0030] Chemical composition and mass percent content (wt %) of each embodiment of the present invention of table 1

[0031] Example

C

Si

mn

Al

P

S

Nb

Ti

Se

Nd

1

0.05

1.20

0.21

0.70

0.008

0.006

0.01

0.02

0.04

0.015

2

0.05

1.00

0.17

0.90

0.006

0.007

0.015

0.03

0.02

0.01

3

0.05

1.10

0.19

0.75

0.007

0.006

0.01

0.02

0.03

0.02

4

0.06

1.20

0.16

0.80

0.008

0.006

0.02

0.03

0.04

0.02

5

0.06

1.10

0.20

0.90

0.007

0.005

0.01

0.02

0.03

0.01

6

0.06

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com