Production method of 260-330MPa low-alloy high-strength steel

A production method and low-alloy technology, applied in the production field of 260-330MPa grade low-alloy high-strength steel, can solve the problems of slow heating and cooling speed, fast heating and cooling speed, large difference in yield ratio, etc., and achieve a good combination of strength and plasticity , The effect of good cold forming performance and stable mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

[0024] Embodiment 1-5: The production method of the 260-330MPa grade low-alloy high-strength steel adopts the following composition ratio and specific process.

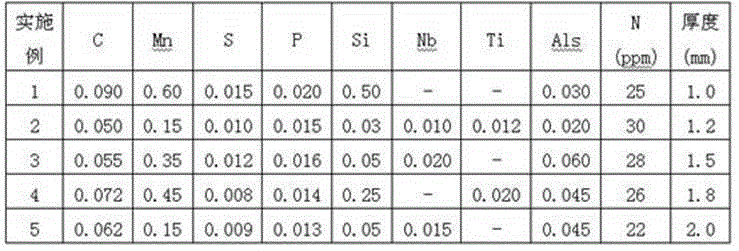

[0025] 1. The weight percent content of the chemical composition of the product in each embodiment and the thickness of the product are shown in Table 1, and the remainder is iron.

[0026] Table 1: Product chemical composition (wt%)

[0027]

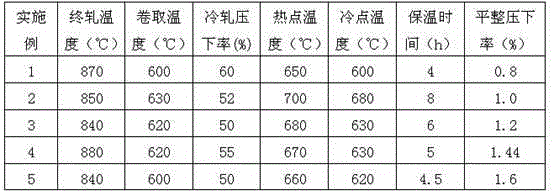

[0028] 2. The specific process conditions of each embodiment are shown in Table 2.

[0029] Table 2: Process Conditions

[0030]

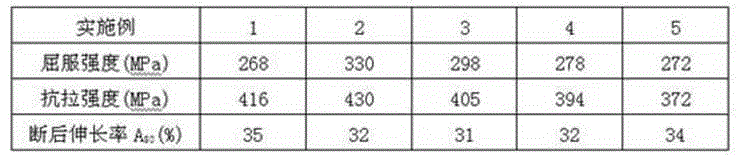

[0031] 3. The mechanical properties of the low-alloy high-strength steel obtained in each embodiment are shown in Table 3.

[0032] Table 3: Product mechanical properties

[0033]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com