Method of producing ring hearth of cored induction furnace

A technology of induction furnace and manufacturing method, applied in furnaces with annular cores, induction heating, etc., can solve problems such as zinc leakage, melting groove deformation, leakage, etc., and achieve natural power factor improvement, flow speed improvement, and optimized design. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

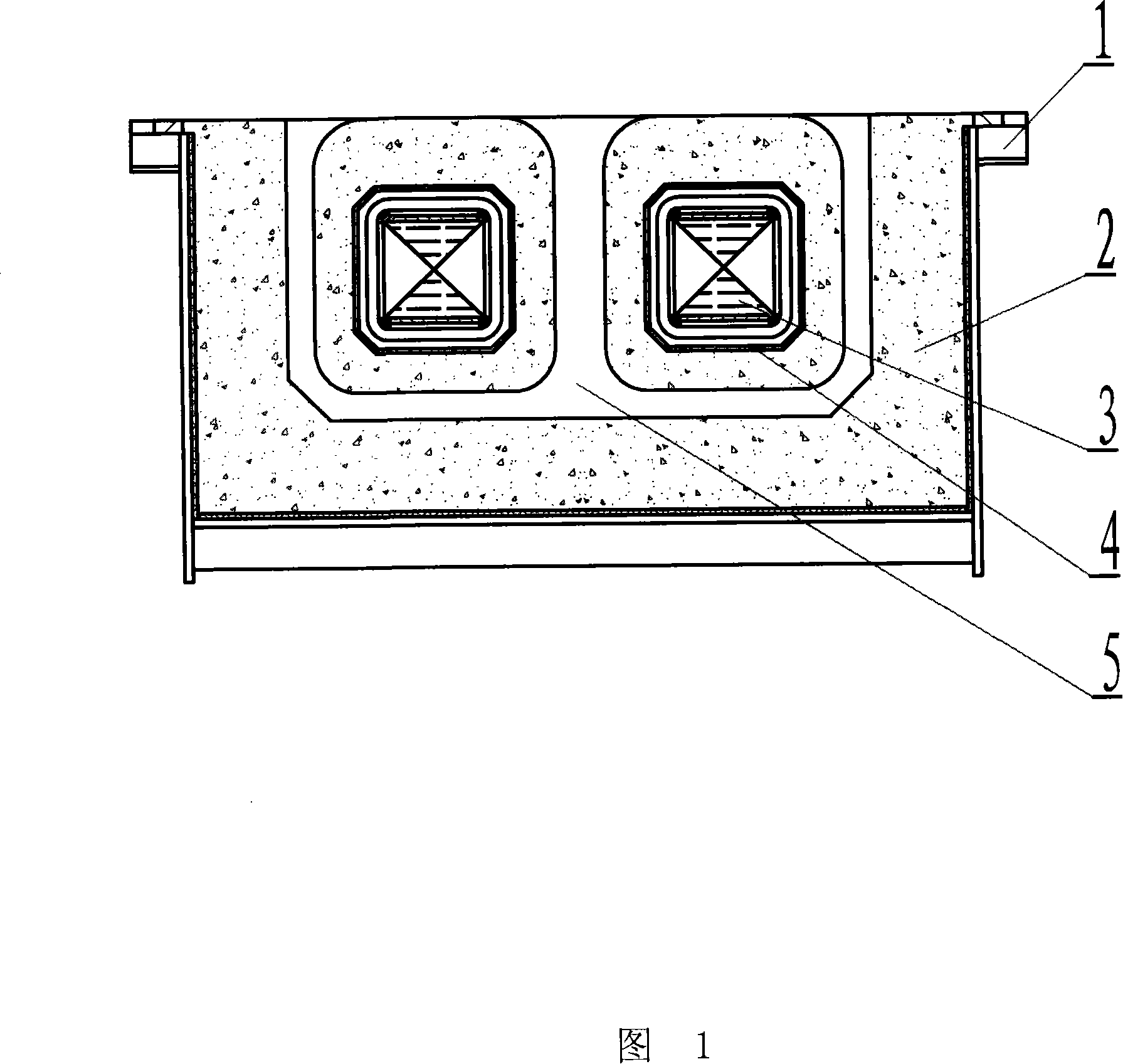

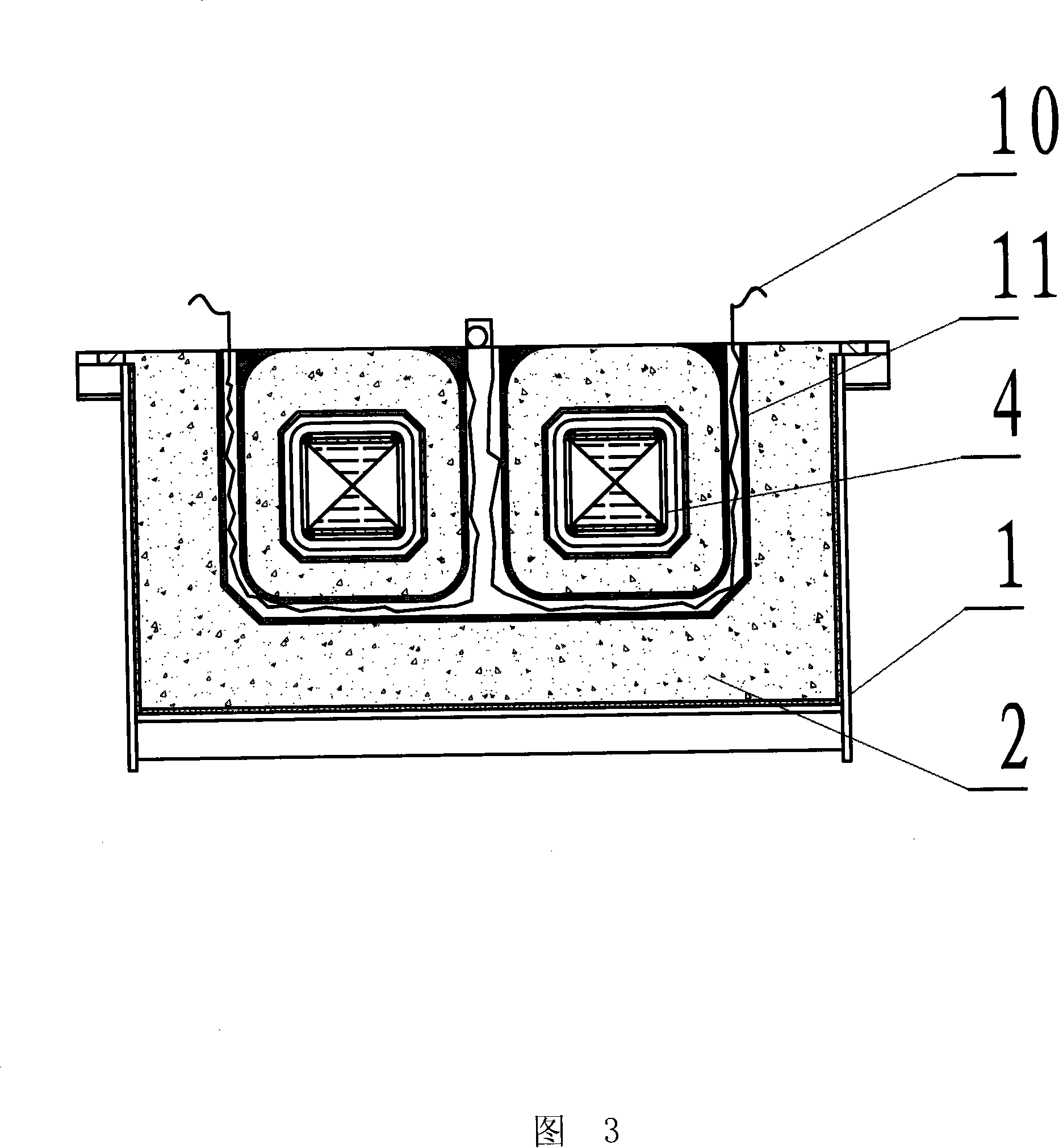

[0026] As shown in Figure 3, according to the specific conditions of the molten metal, the holographic numerical simulation and optimization of the heating and flow of the liquid metal in the molten channel are carried out on the computer, the optimal technical parameters are determined, and the optimized molten channel drawing is designed.

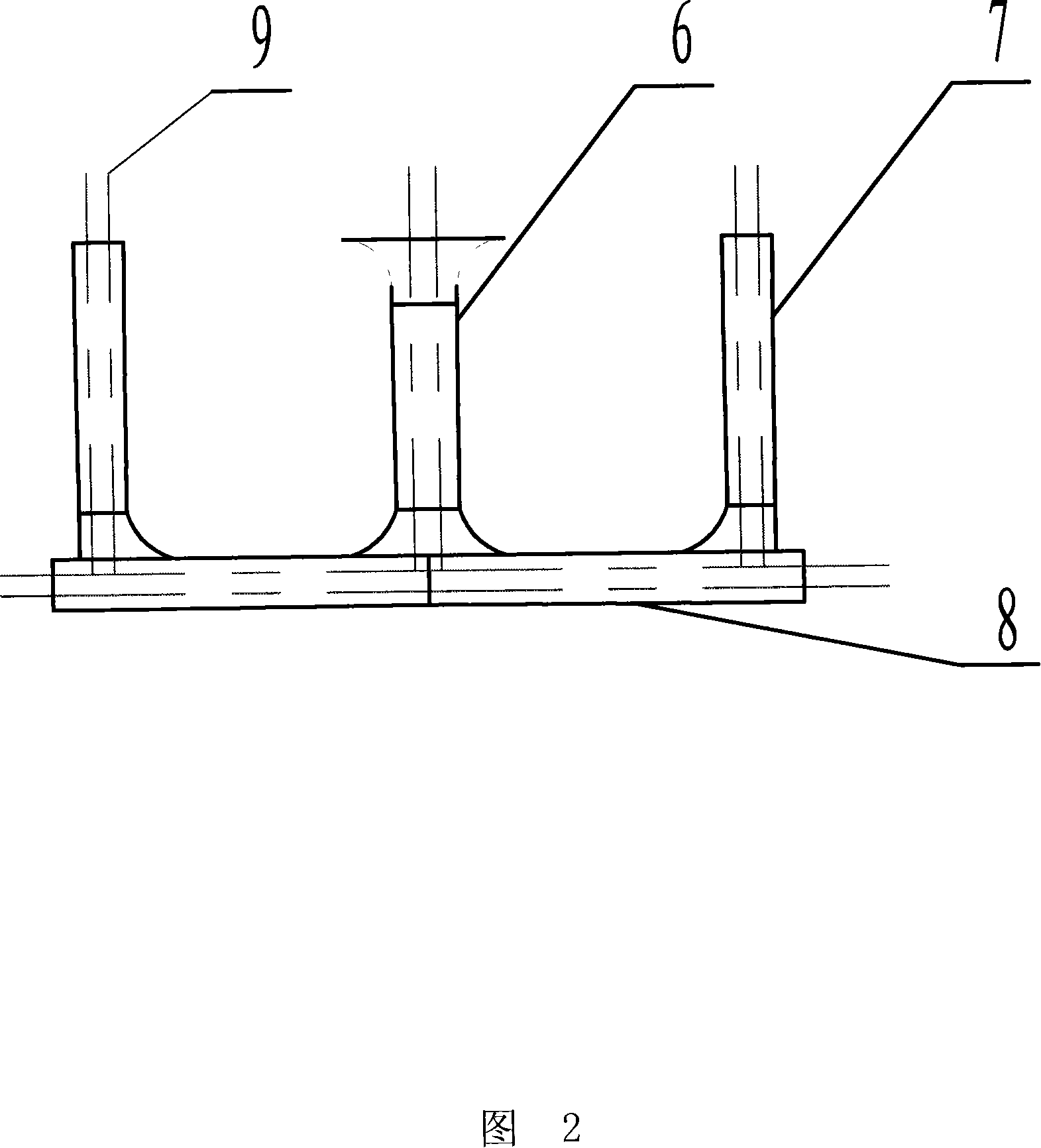

[0027] Use strong and dry wood to make a mold (hollow) that fully meets the optimal technical parameters described in the previous paragraph, and then use superglue and bamboo pins to connect each section into a melt channel mold with a coherent cavity inside. The surface is brushed The insulating varnish is applied multiple times and baked repeatedly to form a layer of anti-seepage protective film on the surface of the wooden formwork to ensure no deformation and no water immersion.

[0028] Fix the mold inside the induction body wood case.

[0029] Fix the stainless steel sleeve 4.

[0030] Pouring refractory material.

[0031] After ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com