Construction method for integrally translating box culvert full framing

A technology of full house support and construction method, which is applied in the direction of house structure support, house structure support, road bottom and other directions, can solve the problems such as the overall translation of the full house support that has not been discussed and researched, the removal of many occupants and mechanical equipment, and the interference of logistics and traffic. , to achieve the effect of easy control of template assembly quality, shortened construction cycle time, and novel tooling equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0038]Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments. Based on the embodiments in the present invention, all other embodiments obtained by those of ordinary skill in the art are in the range of the invention.

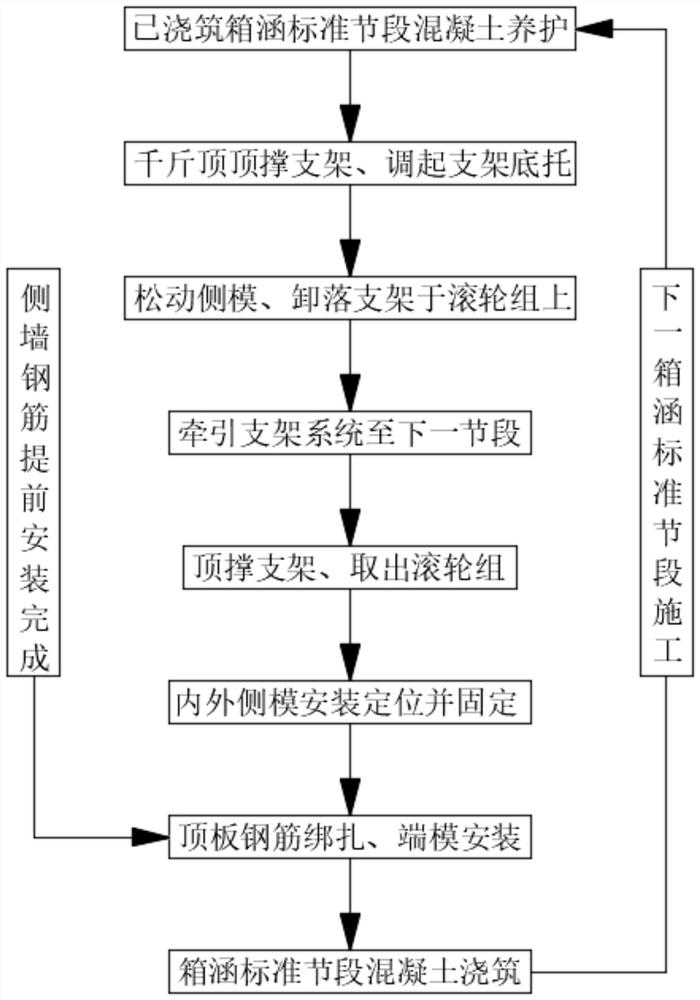

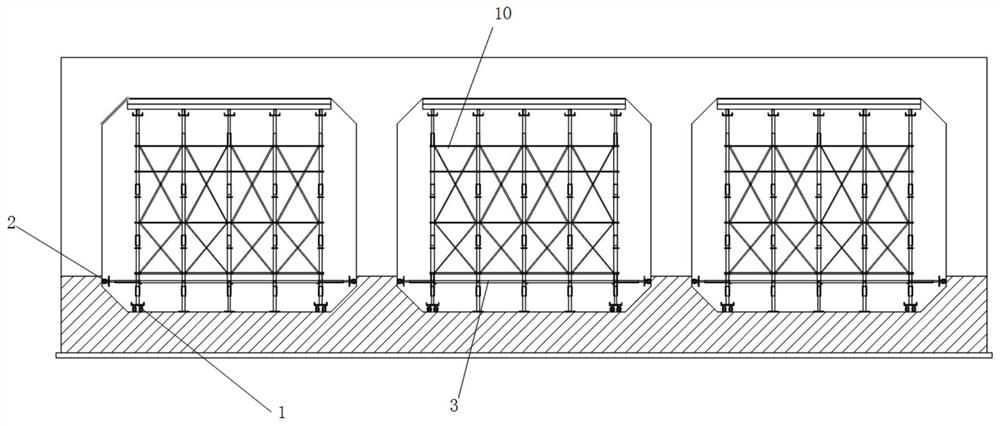

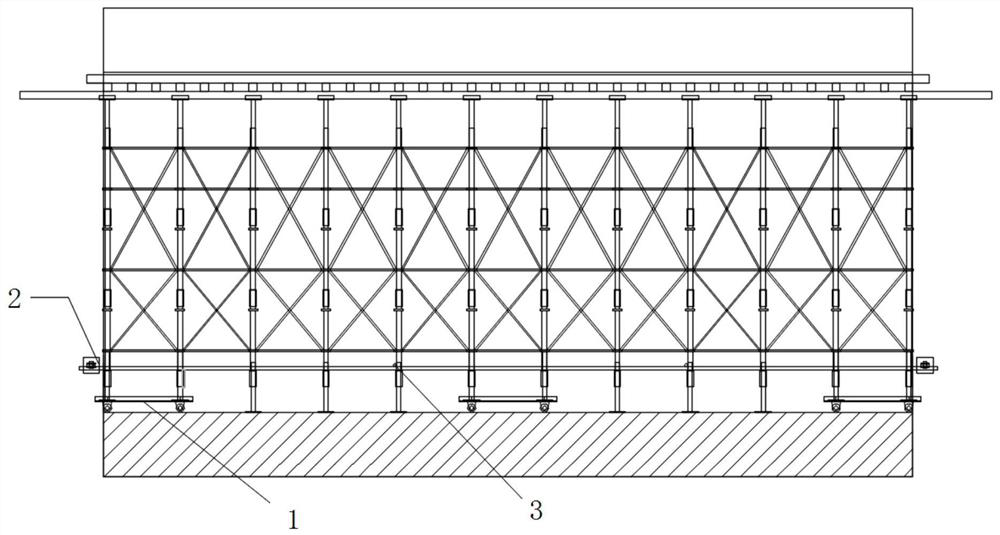

[0039]Such asfigure 1 As shown, the overall translation of a box, which is integrated in accordance with an embodiment of the present invention, specifically, including the following steps:

[0040]S1, in the area of the casting box, which is currently planned, the full set of brackets is set;

[0041]S2, fix the mounting box guide 20 on the full house holder 10, and the steel binding and concrete construction of the box culvert;

[0042]S3, the maintenance of concrete in the box, ensuring that the structural concrete strength meets the design...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vertical distance | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com