Preparation method of hot-rolled acid-washing high-strength steel for automobile carriage

A hot-rolled pickling, high-strength steel technology, applied in the fields of metal materials, steel smelting and controlled rolling and controlled cooling, can solve the problems of not being used for hot-rolled pickling, increasing production processes and costs, high Si content, etc. Good market development prospects, improved surface finish, good surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

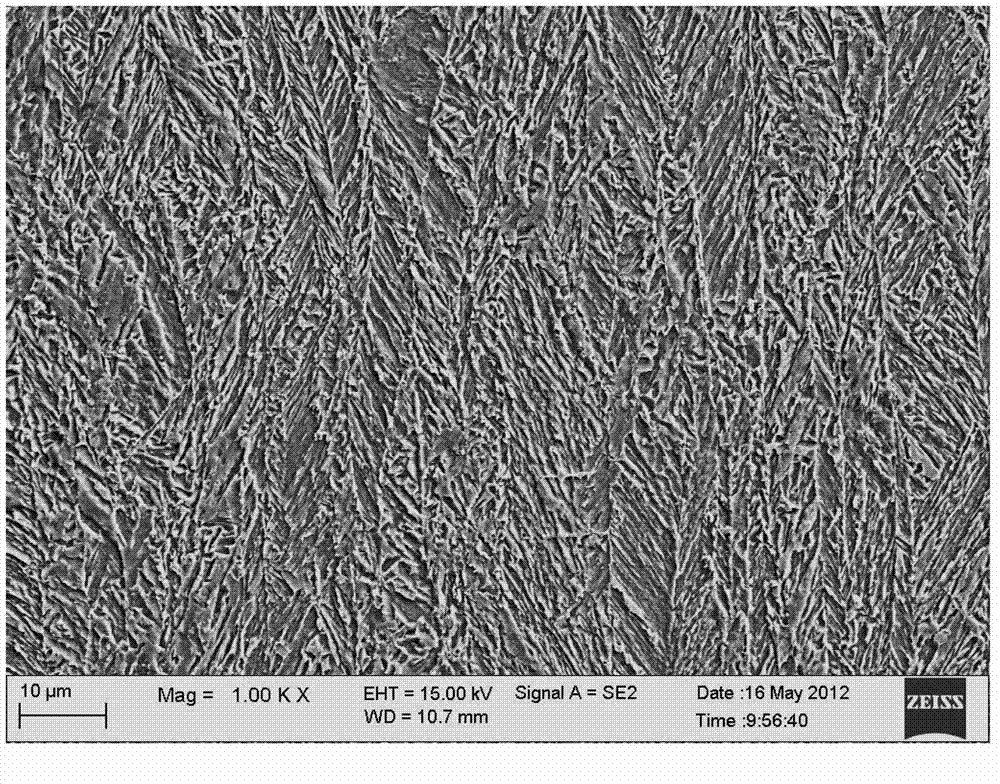

Image

Examples

Embodiment 1

[0036] The specific composition of the cast slab in this embodiment is: C: 0.09%, Si: 0.03%, Mn: 1.79%, Mo: 0.16%, Nb: 0.048%, Ti: 0.16%, Al: 0.025%, B: 0.0025%, P: 0.006%, S: 0.006%, Ca: 0.004%, the rest is Fe and unavoidable impurities, of which the carbon equivalent Ceq=0.42, which ensures excellent weldability.

[0037] The specific production process is carried out according to the following steps:

[0038] 1) Billet heating: heat the billet to 1220~1260°C, keep it warm for 2h~2.5h, and austenitize the composition;

[0039] 2) Rolling in the recrystallization zone: the starting temperature of rolling in the recrystallization zone is 1150°C, rolling 3 passes, and the final rolling temperature in the recrystallization zone is controlled at 1030~1050°C to obtain an intermediate billet, which is then rolled in the recrystallization zone The reduction rate of each pass is controlled at 25%~40%.

[0040] 3) Rolling in the non-recrystallized area: when the intermediate billet ...

Embodiment 2

[0046] The specific composition of the cast slab in this embodiment is: C: 0.10%, Si: 0.02%, Mn: 1.70%, Mo: 0.15%, Nb: 0.050%, Ti: 0.18%, Al: 0.020%, B: 0.003%, P: 0.006%, S: 0.006%, Ca: 0.006%, the rest is Fe and unavoidable impurities, of which the carbon equivalent Ceq=0.41, which ensures excellent weldability.

[0047] The specific production process is carried out according to the following steps:

[0048] 1) Billet heating: heat the billet to 1220~1260°C, keep it warm for 2h~2.5h, and austenitize the composition;

[0049] 2) Rolling in the recrystallization zone: the starting temperature of rolling in the recrystallization zone is 1150°C, rolling 3 passes, and the final rolling temperature in the recrystallization zone is controlled at 1030~1050°C to obtain an intermediate billet, which is then rolled in the recrystallization zone The reduction rate of each pass is controlled at 25%~40%.

[0050] 3) Rolling in the non-recrystallized area: when the intermediate billet i...

Embodiment 3

[0056] The specific composition of the slab in this embodiment is by weight percentage: C: 0.09%, Si: 0.03%, Mn: 1.80%, Mo: 0.15%, Nb: 0.050%, Ti: 0.19%, Al: 0.025%, B: 0.002%, P: 0.006%, S: 0.006%, Ca: 0.005%, the rest is Fe and unavoidable impurities, of which the carbon equivalent Ceq=0.42, which ensures excellent weldability.

[0057] The specific production process is carried out according to the following steps:

[0058] 1) Billet heating: heat the billet to 1220~1260°C, keep it warm for 2h~2.5h, and austenitize the composition;

[0059] 2) Rolling in the recrystallization zone: the starting temperature of rolling in the recrystallization zone is 1150°C, rolling 3 passes, and the final rolling temperature in the recrystallization zone is controlled at 1030~1050°C to obtain an intermediate billet, which is then rolled in the recrystallization zone The reduction rate of each pass is controlled at 25%~40%.

[0060] 3) Rolling in the non-recrystallized area: when the inter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com