Thin-wall high-strength hot rolled strip steel for square rectangular tube and manufacturing method thereof

A hot-rolled steel strip and manufacturing method technology, applied in the field of iron and steel smelting and rolling, can solve the problems that square and rectangular tubes cannot meet the requirements of the bus body frame, and achieve excellent plate shape and surface quality, excellent cold formability, high The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

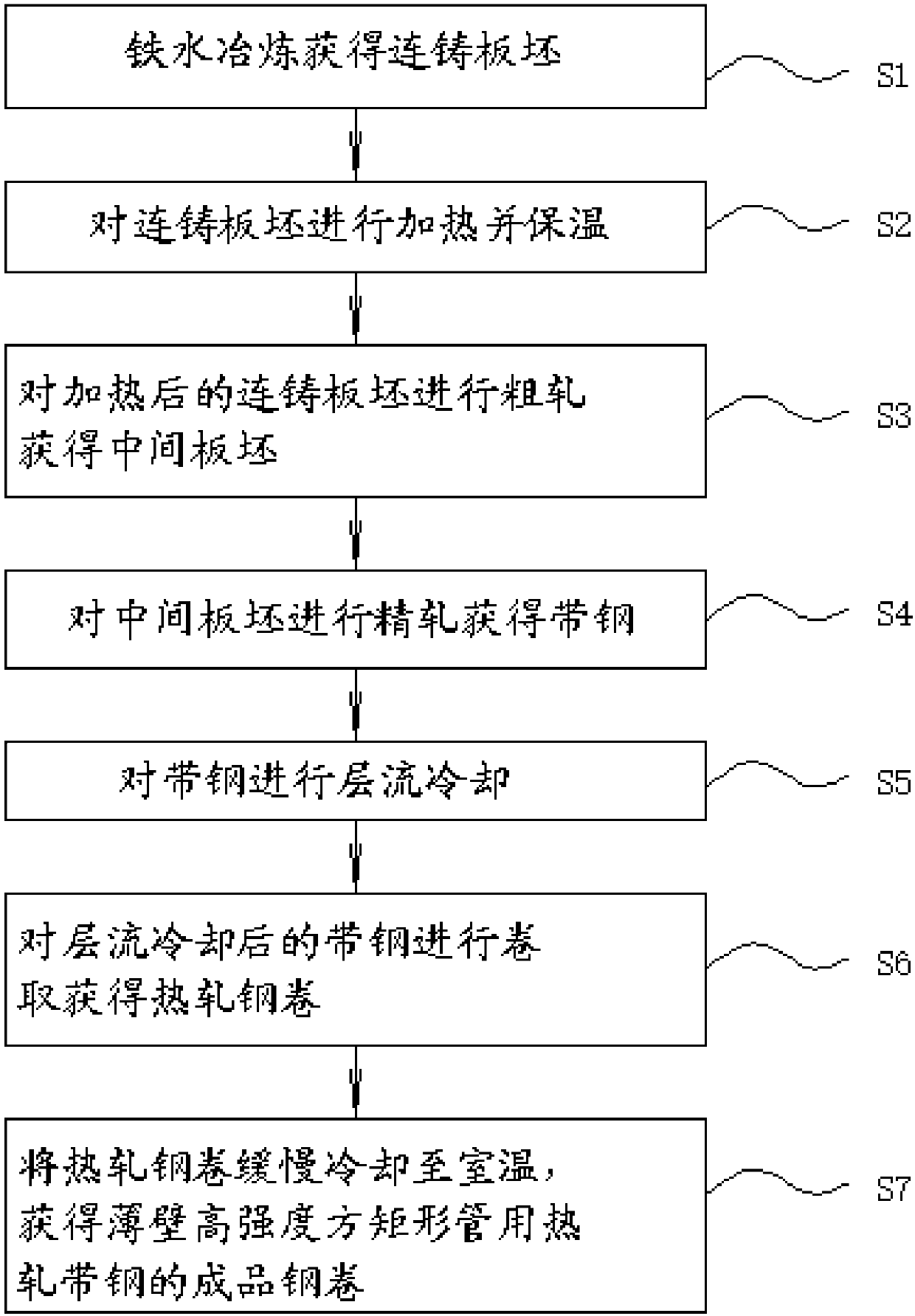

Method used

Image

Examples

Embodiment Construction

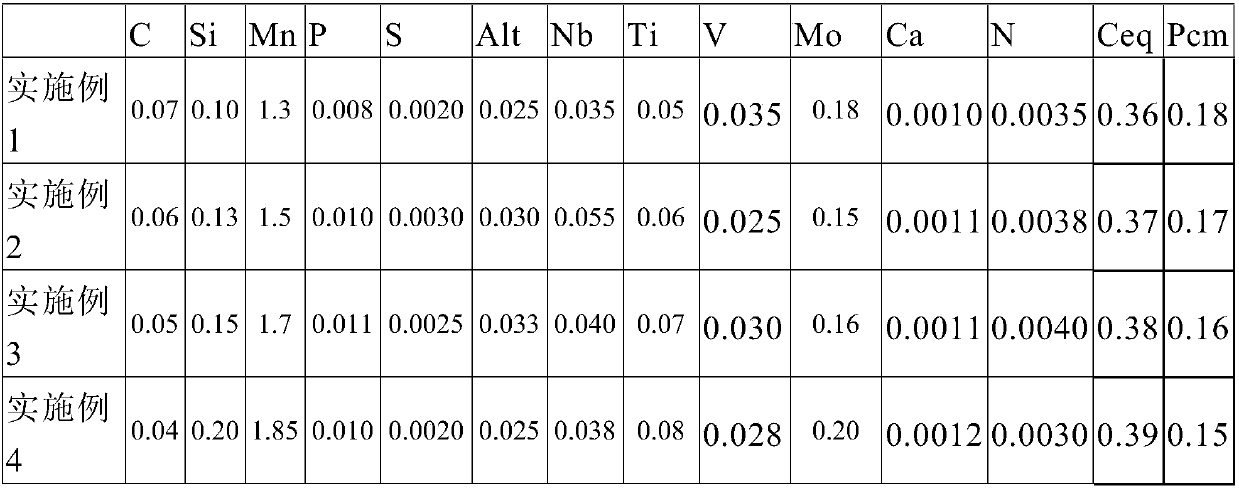

[0034] The embodiment of the present application provides a hot-rolled steel strip for thin-walled high-strength square rectangular pipe and its manufacturing method, which solves or partially solves the technical problem that the square rectangular pipe in the prior art cannot meet the use requirements of the bus body frame. Proportioning the chemical composition elements of the hot-rolled steel strip for square rectangular pipes to obtain a microstructure with excellent cold formability and fatigue properties; The yield strength of the steel plate can reach more than 800MPa, the tensile strength can reach more than 850MPa, the fluctuation of the tensile strength is within 60MPa, the elongation rate can reach more than 24%, the plate shape and surface quality are excellent, and it has excellent cold formability and weldability. Roll forming produces structural parts such as square and rectangular tubes and the reprocessing requirements of finished tubes, which meet the technic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com