600MPa level hot rolling thin steel plate and manufacturing method thereof

A technology of hot-rolled thin steel plate and manufacturing method, which is applied in metal rolling, temperature control, etc., can solve the problems of no production technology, etc., and achieve the effects of reducing transportation costs, strong compression resistance, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Introduce the specific embodiment of the present invention below

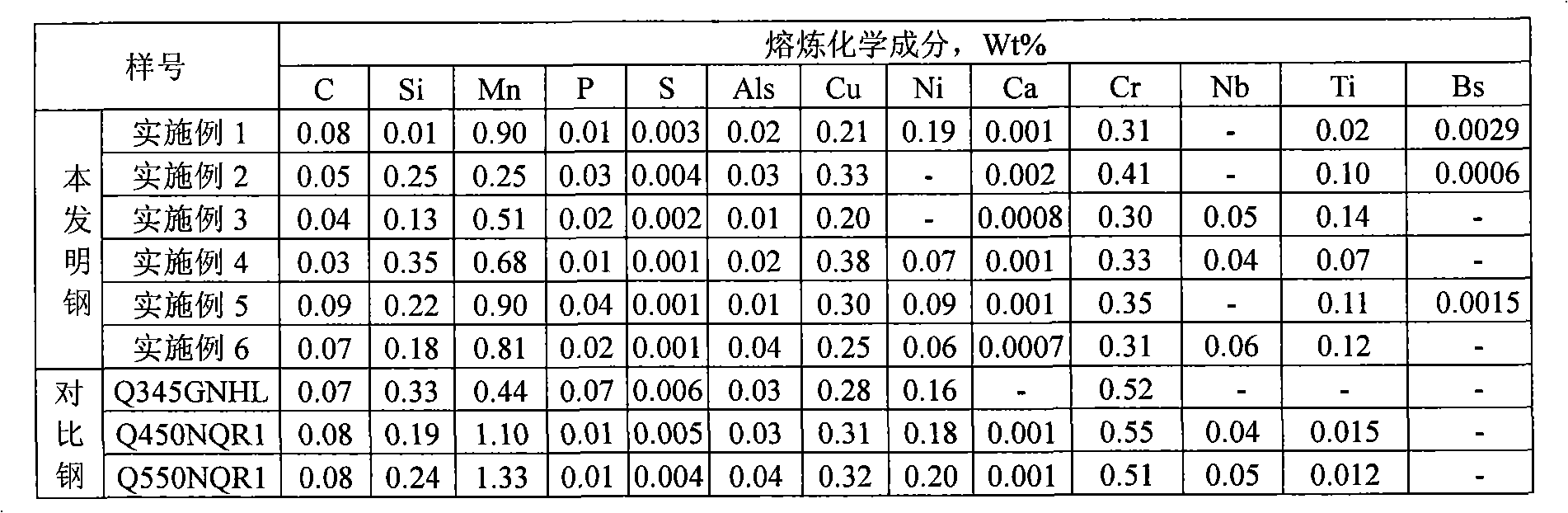

[0039] The weight percentage of steel chemical composition of the present invention is:

[0040] C: 0.02% to 0.09%, Si: 0.01% to 0.35%, Mn: 0.20% to 0.90%, P: 0.04% or less, S: 0.005% or less, Ni: 0.20% or less, Cu: 0.2% to 0.4%, Cr: 0.30% to 0.45%, Als: 0.005% to 0.050%, Ca: 0.0005% to 0.005%, Ti: 0.02% to 0.15%, and contains Nb: 0% to 0.070%, Bs: 0% to 0.003% One or more, the balance is Fe and unavoidable impurities.

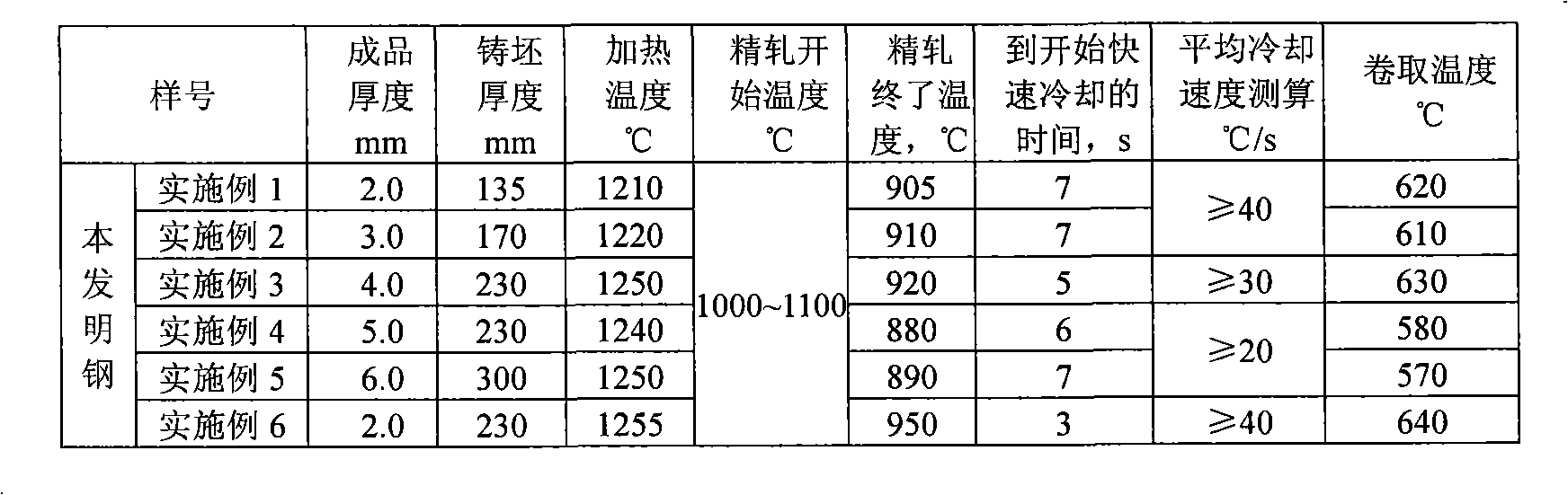

[0041] After the steel with the above chemical composition is continuously cast into a slab with a thickness of 120-300mm, the production process is characterized by rough rolling at a temperature higher than 1040°C after being uniformly heated at 1260-1200°C. Finish rolling starts at 1100-1000°C, ends rolling at 950-880°C, and coils at 550-650°C after cooling at a cooling rate of 20°C / s or more within 10s after rolling.

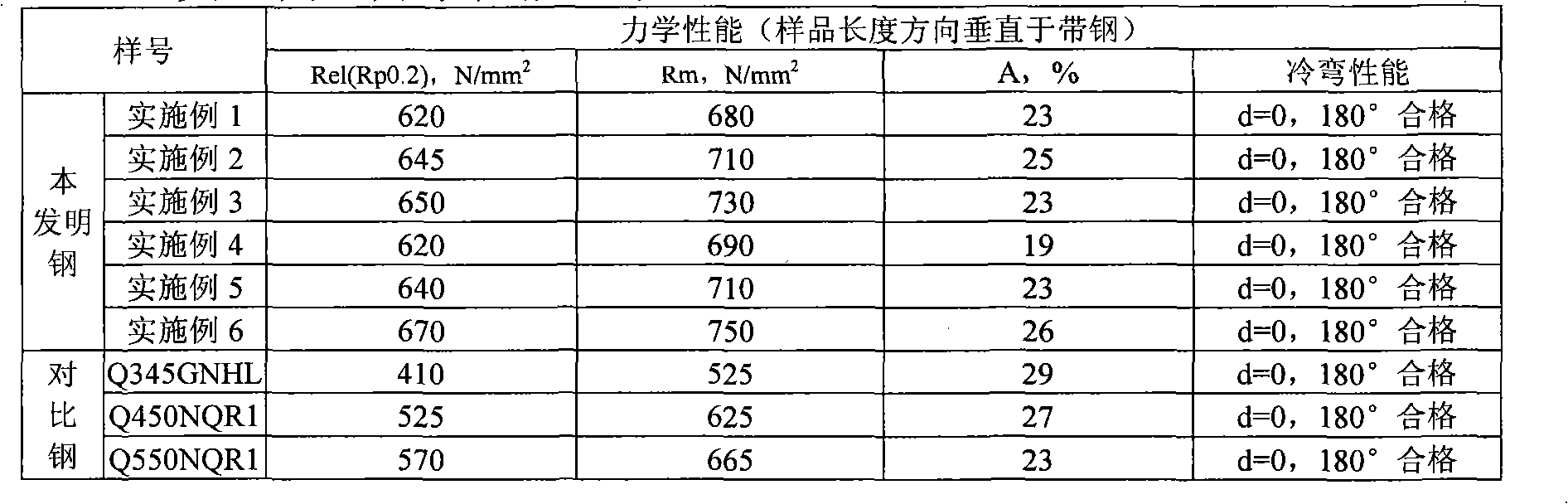

[0042] Tables 1 to 3 are several examples produced according t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com