800MPa-grade heavy-gauge hot-rolled high-strength steel plate roll with excellent low-temperature toughness for cold forming and manufacturing method thereof

A low-temperature toughness, high-strength steel plate technology, applied in the direction of manufacturing converters, etc., can solve the problem of high alloy cost, achieve the effect of reducing production cost, excellent shape and surface quality, and reducing manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The present invention will be further described in detail below in conjunction with specific embodiments.

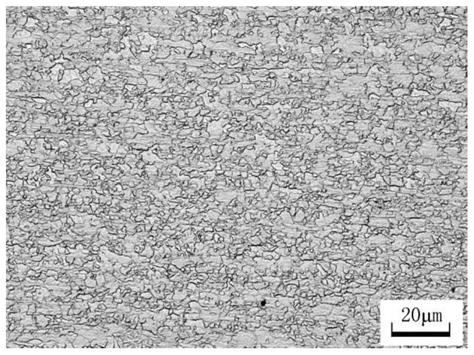

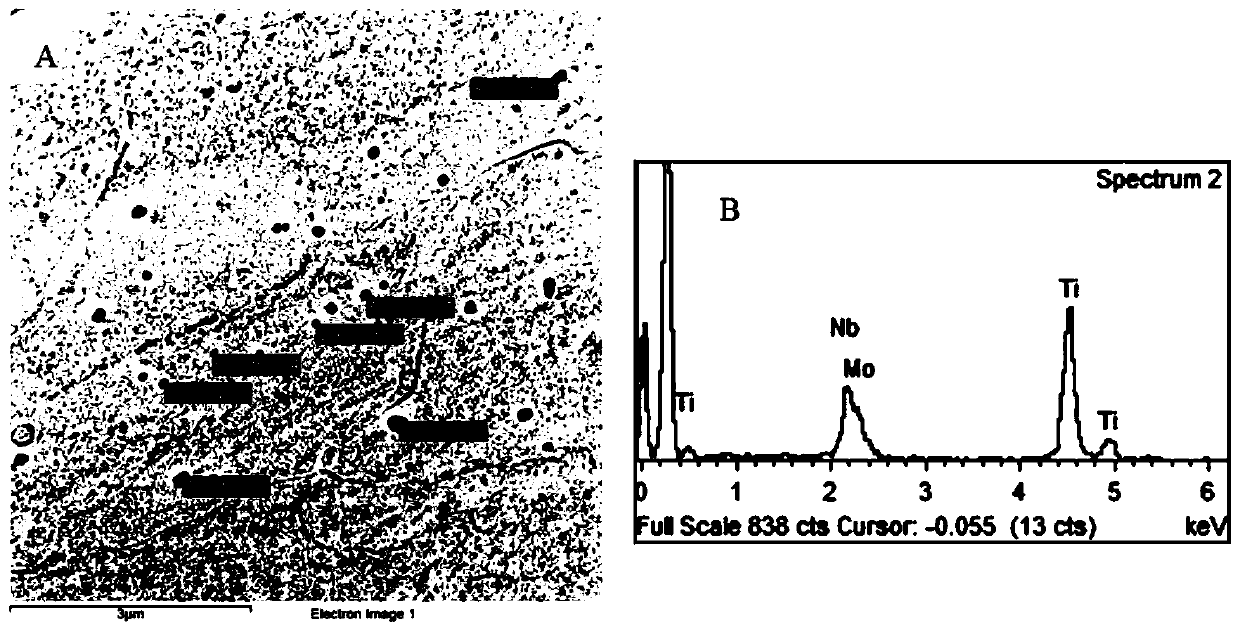

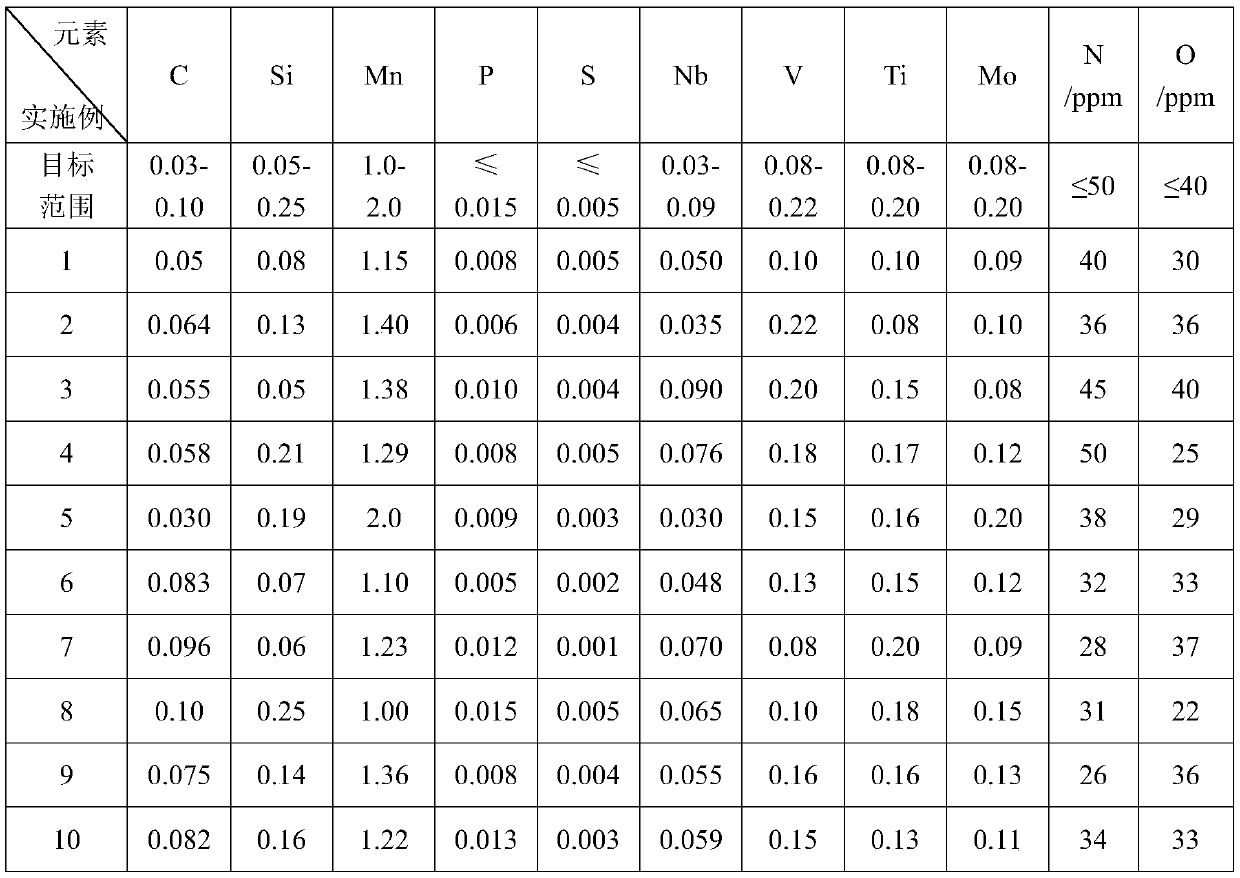

[0060] The thick-gauge hot-rolled high-strength steel sheet coil for 800MPa grade cold forming of the present invention has excellent low-temperature toughness, and its chemical composition weight content is: C: 0.03-0.10%, Si: 0.05-0.25%, Mn: 1.0-2.0%, P≤ 0.015%, S≤0.005%, Nb: 0.03~0.09%, V: 0.08~0.22%, Ti: 0.08~0.20%, Mo: 0.08~0.20%, N≤50ppm, O≤40ppm, the balance is Fe or not Avoid impurities.

[0061] According to the chemical composition of the above-mentioned 800MPa class cold forming with excellent low temperature toughness combined with the actual situation, a number of embodiments are designed:

[0062] The specific values of the chemical components in each embodiment are shown in Table 1.

[0063] The chemical composition (wt.%) of each embodiment steel strip of table 1

[0064]

[0065] The production process of the hot-rolled high-strength steel s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com