Preparation method of molybdenum rhenium lanthanum alloy material

An alloy material, molybdenum-rhenium technology, applied in the field of preparation of molybdenum-rhenium-lanthanum alloy materials, can solve problems such as poor doping uniformity, increased rhenium content, and increased manufacturing costs of molybdenum-rhenium alloys, so as to improve the performance of molybdenum alloys and expand the scope of use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

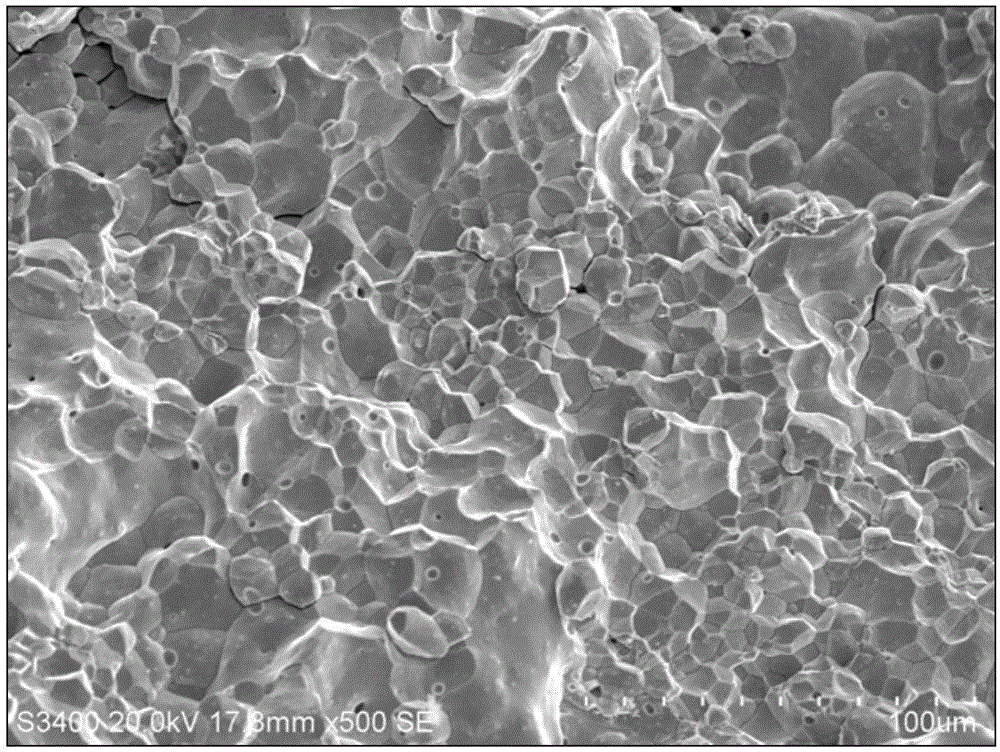

Embodiment 1

[0029] The preparation method of the molybdenum-rhenium-lanthanum alloy material in this embodiment comprises the following steps:

[0030] Step 1. At first, the composition of the molybdenum-rhenium-lanthanum alloy material is designed so that the alloy material includes the following metal components in mass percentages: Re 1.0%, La 2.0%, and the balance is Mo; then, weigh them respectively according to the designed composition Get nano-lanthanum oxide powder (mass purity 99.99%, particle size 30nm), rhenium powder (mass purity 99.99%, particle size 30nm) and molybdenum dioxide powder (mass purity 96.2%, particle size is 3 μm, molybdenum content 72% in the molybdenum dioxide powder );

[0031] In the present embodiment, the mass m of the nano-lanthanum oxide powder taken 1 =2.35×10 3 g, the mass of rhenium powder weighed is 1.0×10 3 g, the mass of the molybdenum dioxide powder taken is 134.72×10 3 g;

[0032] Step 2, take nano lanthanum oxide powder again, the quality o...

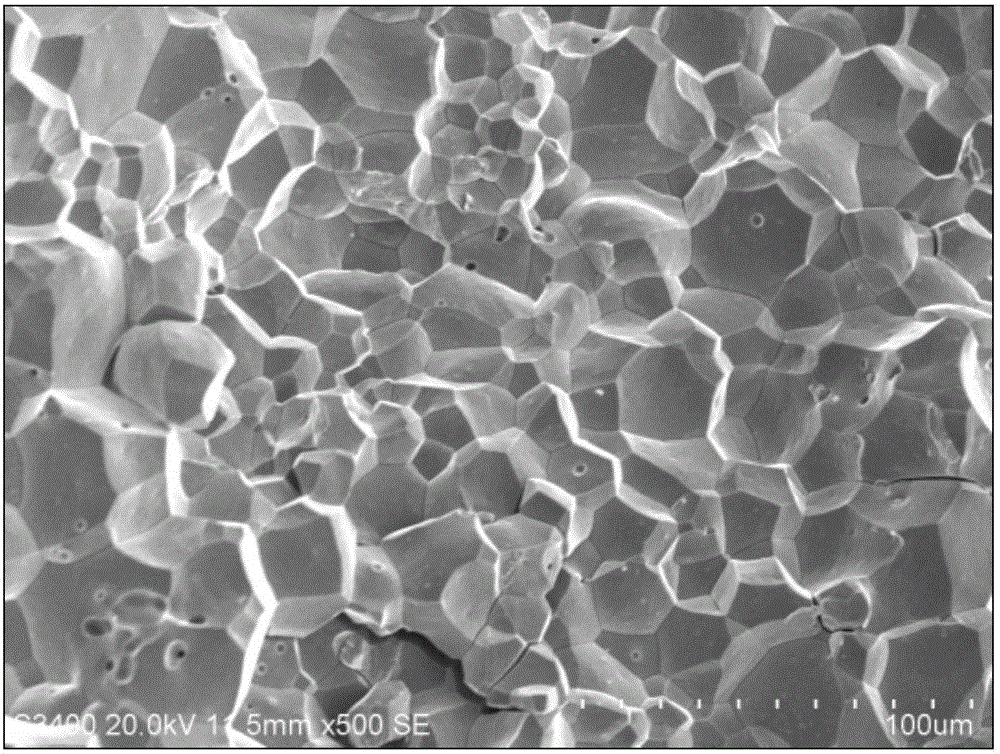

Embodiment 2

[0040] The preparation method of the molybdenum-rhenium-lanthanum alloy material in this embodiment comprises the following steps:

[0041] Step 1. At first, the composition of the molybdenum-rhenium-lanthanum alloy material is designed so that the alloy material includes the following metal components in mass percentages: Re 5.0%, La 0.2%, and the balance is Mo; then, weigh them respectively according to the designed composition Get nano-lanthanum oxide powder (mass purity 99.99%, particle size 80nm), rhenium powder (mass purity 99.99%, particle size 1 μm) and molybdenum dioxide powder (mass purity 97.3%, particle size 10 μm, molybdenum content 73% in the molybdenum dioxide powder );

[0042] In the present embodiment, the mass m of the nano-lanthanum oxide powder taken 1 =234.5g, the quality of the rhenium powder taken is 5.0×10 3 g, the mass of the molybdenum dioxide powder taken is 129.9×10 3 g;

[0043] Step 2, take nano lanthanum oxide powder again, the quality of th...

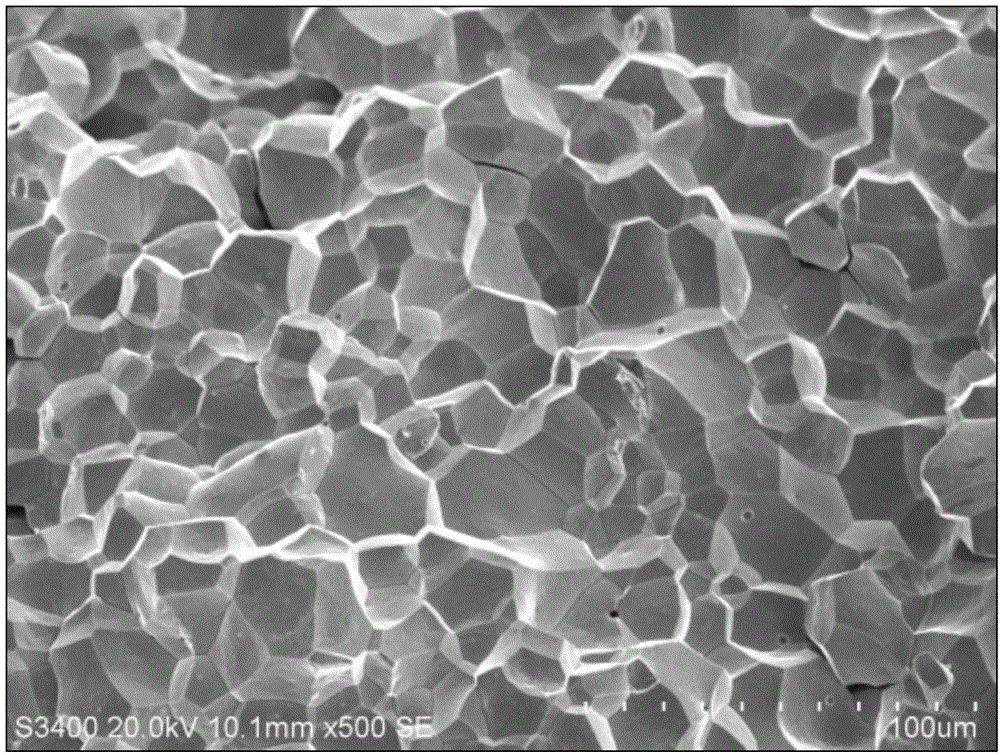

Embodiment 3

[0051] The preparation method of the molybdenum-rhenium-lanthanum alloy material in this embodiment comprises the following steps:

[0052] Step 1. At first, the composition of the molybdenum-rhenium-lanthanum alloy material is designed so that the alloy material includes the following metal components in mass percentages: Re 1.0%, La 0.02%, and the balance is Mo; then, weigh them respectively according to the designed composition Get nano-lanthanum oxide powder (mass purity 99.99%, particle size 50nm), rhenium powder (mass purity 99.99%, particle size 0.1 μm) and molybdenum dioxide powder (mass purity 98.7%, particle size is 5 μm, molybdenum content in the molybdenum dioxide powder is 74 %);

[0053] In the present embodiment, the mass m of the nano-lanthanum oxide powder taken 1 =23.5g, the quality of the rhenium powder taken is 1.0×10 3 g, the mass of the molybdenum dioxide powder taken is 133.8×10 3 g;

[0054] Step 2, take nano lanthanum oxide powder again, the qualit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com