Aluminum alloy material, conducting bar and calculation method of creep residual life of conducting bar

A technology of aluminum alloy materials and calculation methods, applied in the field of power transmission and distribution, can solve problems such as failure of connection areas, achieve the effects of improving high temperature creep performance, increasing recrystallization temperature, and reducing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

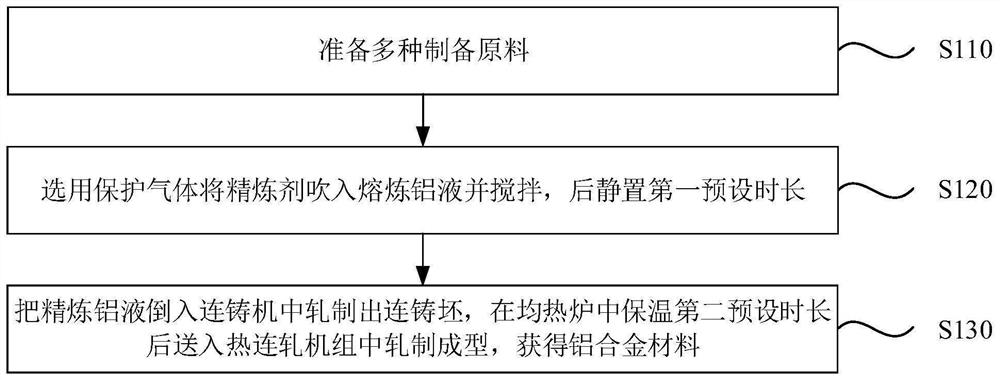

[0063] On the basis of the above-mentioned embodiments, the embodiments of the present invention also provide a method for preparing an aluminum alloy material. figure 1 It is a flow chart of a method for preparing an aluminum alloy material provided by an embodiment of the present invention, such as figure 1 As shown, the preparation method of the aluminum alloy material specifically includes the following steps:

[0064] S110, preparing various preparation raw materials.

[0065] Wherein, S110 is a step of preparing raw materials by proportioning, and the ratio of the prepared raw materials is determined by the element content in the aluminum alloy material provided by any embodiment of the present invention. Exemplarily, the aluminum alloy material includes Al element, Mg element, Cu element, Zr element and the like. Correspondingly, one or more preparation raw materials need to include Al element, Mg element, Cu element, Zr element and the like. It can be understood tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com