Heat-resisting steel and preparation method thereof

A heat-resistant steel and molten steel technology, applied in the field of alloy steel, can solve the problems of lower yield, affecting the use efficiency of rare earth elements, and less addition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The present invention also provides a preparation method for the above-mentioned heat-resistant steel, comprising the following steps:

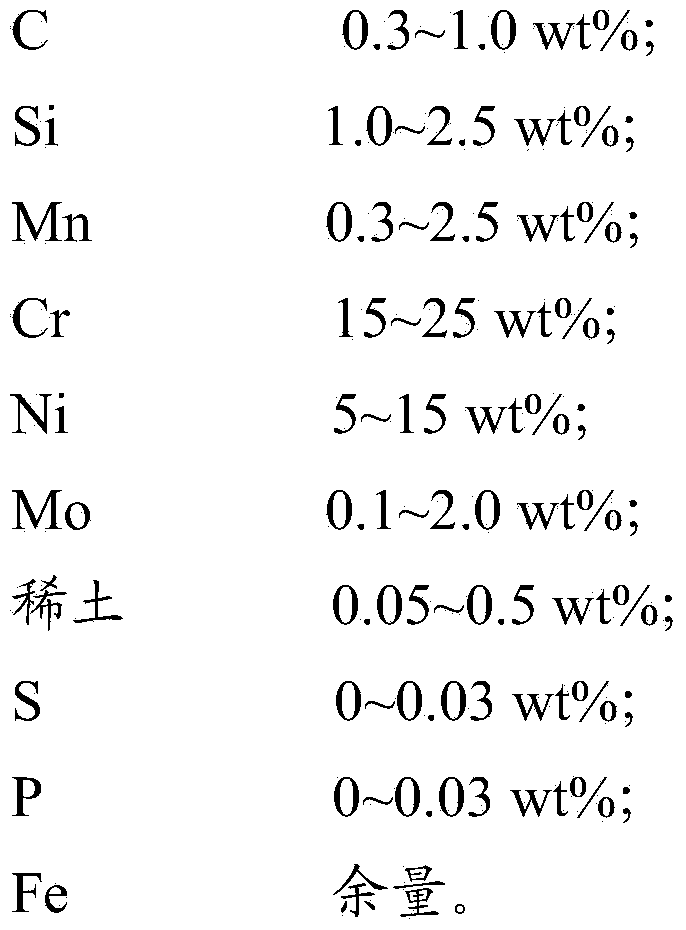

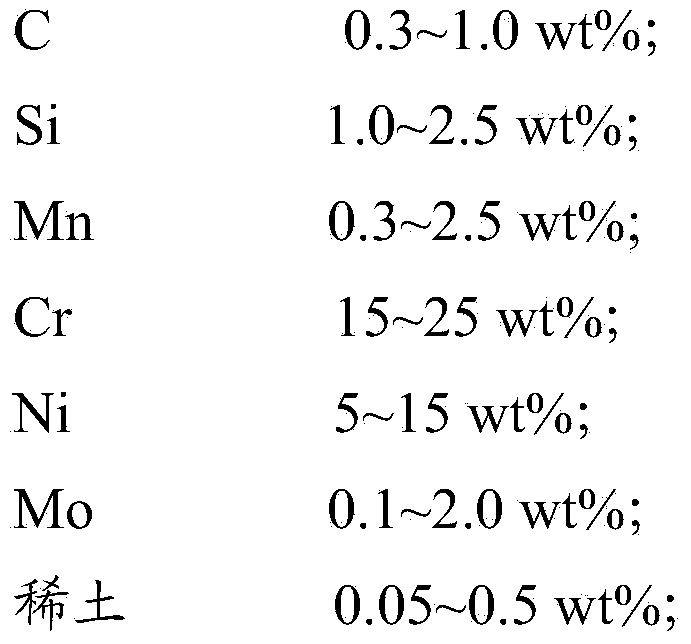

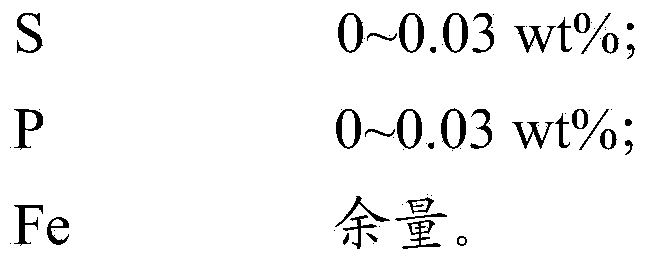

[0038] The first mass part of Fe and 0.3-1.0wt% of C, 1.0-2.5wt% of Si, 0.3-2.5wt% of Mn, 15-25wt% of Cr, 5-15wt% of Ni, 0.1-2.0wt% % Mo, 0-0.03wt% S, 0-0.03wt% P mixed and smelted to obtain molten steel;

[0039] Covering the surface of 0.05 to 0.5 parts by weight of the second part by mass of Fe, pouring the molten steel into the molten steel, and standing still to obtain heat-resistant steel;

[0040] The particle size of the rare earth is nanoscale and / or micronscale.

[0041] Wherein, the raw materials are the same as above, and will not be repeated here.

[0042] According to the present invention, the specific steps of mixing and smelting are: mixing and heating the first mass part of Fe with 0.3-1.0wt% of C, 0-0.03wt% of S, and 0-0.03wt% of P until melted, Preferably heated to 1200°C-1400°C, then added 1.0-2.5wt% Si and 0.3-2....

Embodiment 1

[0056] 1.1 According to the composition of raw material elements: 0.3wt% C, 1.0wt% Si, 2.5wt% Mn, 15wt% Cr, 5.0wt% Ni, 2.0wt% Mo, 0.05wt% Y, S≤0.03 wt%, P≤0.03wt% and the balance of Fe. Weigh mineral raw materials scrap steel, ferromanganese, ferrosilicon, ferrochromium, pure nickel, ferromolybdenum and rare earth Y, with a total weight of 200kg.

[0057] 1.2 Manually crush 0.1kg of rare earth Y weighed in 1.1 to about 2-3 mm, then add it to a ball mill tank, add an ethanol solution with 0.5% weight of rare earth Y, and then add stainless steel grinding balls (two sizes of grinding balls) Ball size: 10mm and 5mm; the weight ratio of the two kinds of grinding balls is 1:1), the ball-to-material ratio is 10:1, and the vacuum is sealed to 10 -1 Pa, filled with argon, and ball milled for 20 hours to obtain rare earth Y powder with an average particle size of 300 μm, which is sealed and stored.

[0058] 1.3 Heat the steel scrap weighed in 1.1 to 1400°C in a 200kg medium-frequency...

Embodiment 2

[0066] 2.1 According to the composition of raw material elements: 1.0wt% C, 2.5wt% Si, 0.3wt% Mn, 25wt% Cr, 15wt% Ni, 0.1wt% Mo, 0.15wt% Y, S≤0.03wt %, P≤0.03wt% and the balance of Fe. Weigh mineral raw materials scrap steel, ferromanganese, ferrosilicon, ferrochromium, pure nickel, ferromolybdenum and rare earth Y, with a total weight of 200kg.

[0067] 2.2 Manually crush 0.3kg of rare earth Y weighed in 2.1 to about 2-3mm, then add it to a ball mill tank, add an ethanol solution with 0.5% weight of rare earth Y, and then add stainless steel grinding balls (two sizes of grinding balls) Ball size: 10mm and 5mm; the weight ratio of the two kinds of grinding balls is 1:1), the ball-to-material ratio is 10:1, and the vacuum is sealed to 10 -1 Pa, filled with argon gas and ball milled for 80 hours to obtain rare earth Y powder with an average particle size of 150nm, which is sealed and stored.

[0068] 2.3 Heat the steel scrap weighed in 2.1 to 1400°C in a 200kg medium-frequency...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com