Novel heat-resistant steel for key hot end part of ultrahigh-parameter steam turbine

A technology for hot end parts and steam turbines is applied in the field of heat-resistant steel, which can solve the problems of limited improvement of high-temperature durability and oxidation resistance of heat-resistant steel, and achieve the effects of improving high-temperature mechanical properties and preventing powder agglomeration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

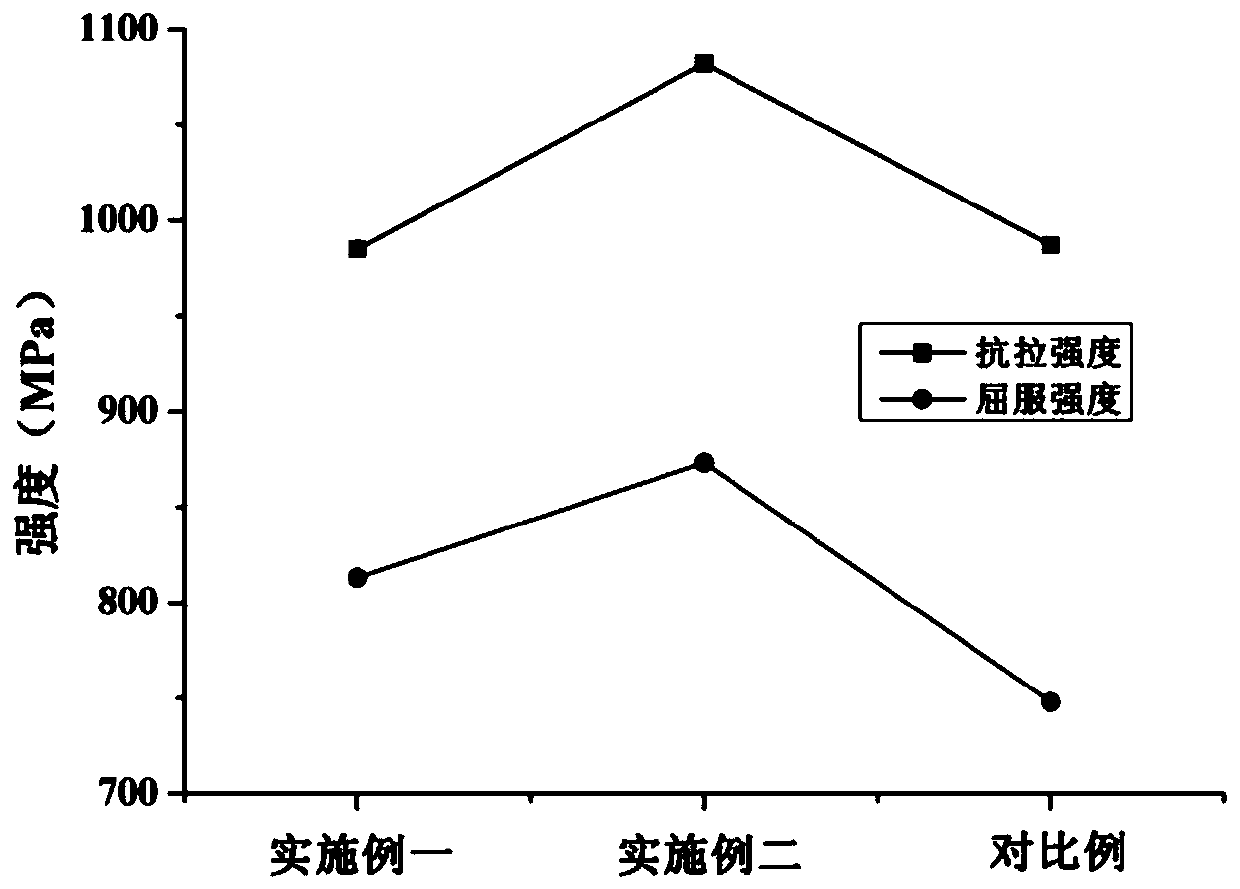

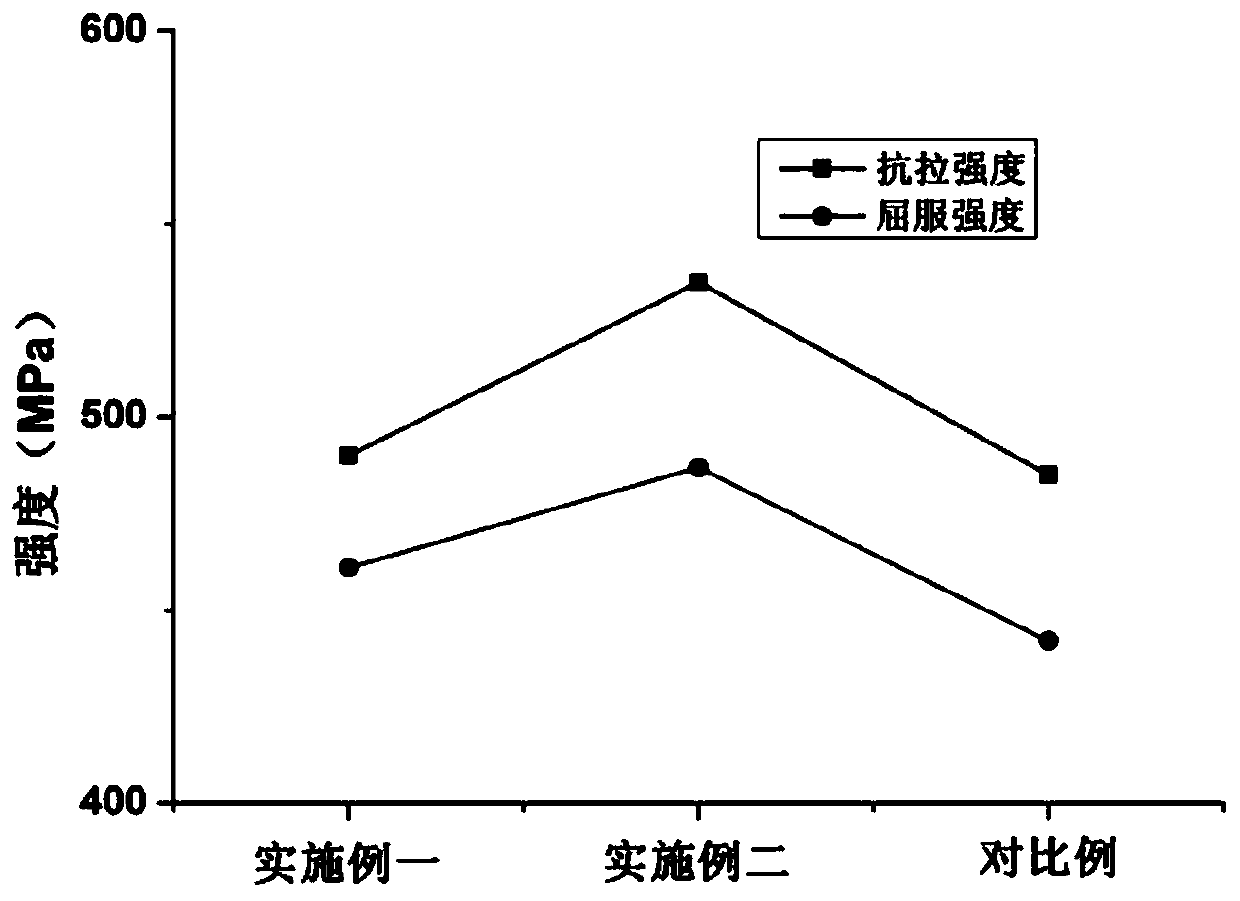

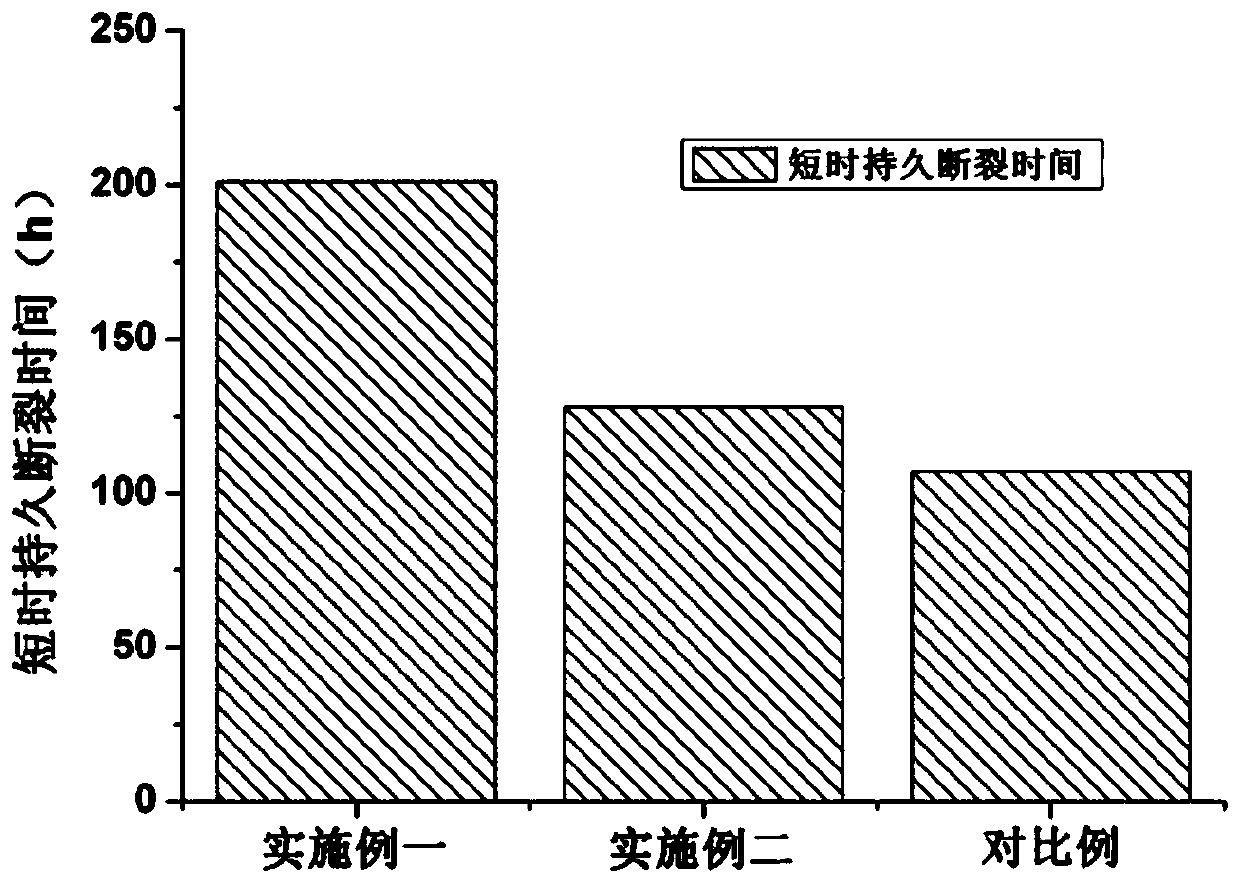

Embodiment 1

[0056] According to the required chemical elements, weigh each component to obtain raw materials, put the raw materials in a vacuum smelting furnace for smelting, add block additives during the vacuum smelting process, and then carry out electroslag remelting smelting to ensure uniform melting, then casting Form a steel ingot, the size of the steel ingot is ψ50, forge the steel ingot, the forging temperature range is 1100-1200°C; then carry out the following treatment on the steel ingot: quenching treatment temperature is 1050°C, holding time 1h, oil cooling or air cooling to room temperature, Then perform a tempering treatment, the tempering temperature is 700°C, the holding time is 4h, air-cooled or air-cooled to room temperature, and then a second tempering treatment is performed, the tempering temperature is 680°C, the holding time is 4h, air-cooled or air-cooled to room temperature room temperature. The weight percentage (%) of each component of the heat-resistant steel: ...

Embodiment 2

[0058] According to the required chemical elements, weigh each component to obtain raw materials, put the raw materials in a vacuum smelting furnace for smelting, add block additives during the vacuum smelting process, and then carry out electroslag remelting smelting to ensure uniform melting, then casting Form a steel ingot, the size of the steel ingot is ψ50, the forging temperature range is 1100-1200°C; then the steel ingot is treated as follows: the quenching temperature is 1050°C, the holding time is 1h, oil cooling or air cooling to room temperature, and then a tempering For processing, the tempering temperature is 680°C, the holding time is 6h, and air-cooled or air-cooled to room temperature. The weight percentage (%) of each component of the heat-resistant steel: C: 0.05, Cr: 9.25, Co: 2.92, W: 2.96, Mo: 0.38, V: 0.15, Ni: 0.43, Nb: 0.08, N: 0.034, B: 0.023, Si: 0.0013, Mn: 0.21, S: 0.0018, P: 0.0010, Y: 0.60.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com