A method for in-situ synthesis of nano-oxide particle dispersion-strengthened alloys

A technology of particle dispersion strengthening and nano-oxide, which is applied in metal processing equipment, improvement of process efficiency, transportation and packaging, etc., can solve problems such as low efficiency, many processes, and difficulty in controlling grain orientation, and achieves simple methods and high process efficiency. The effect of few, simple methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

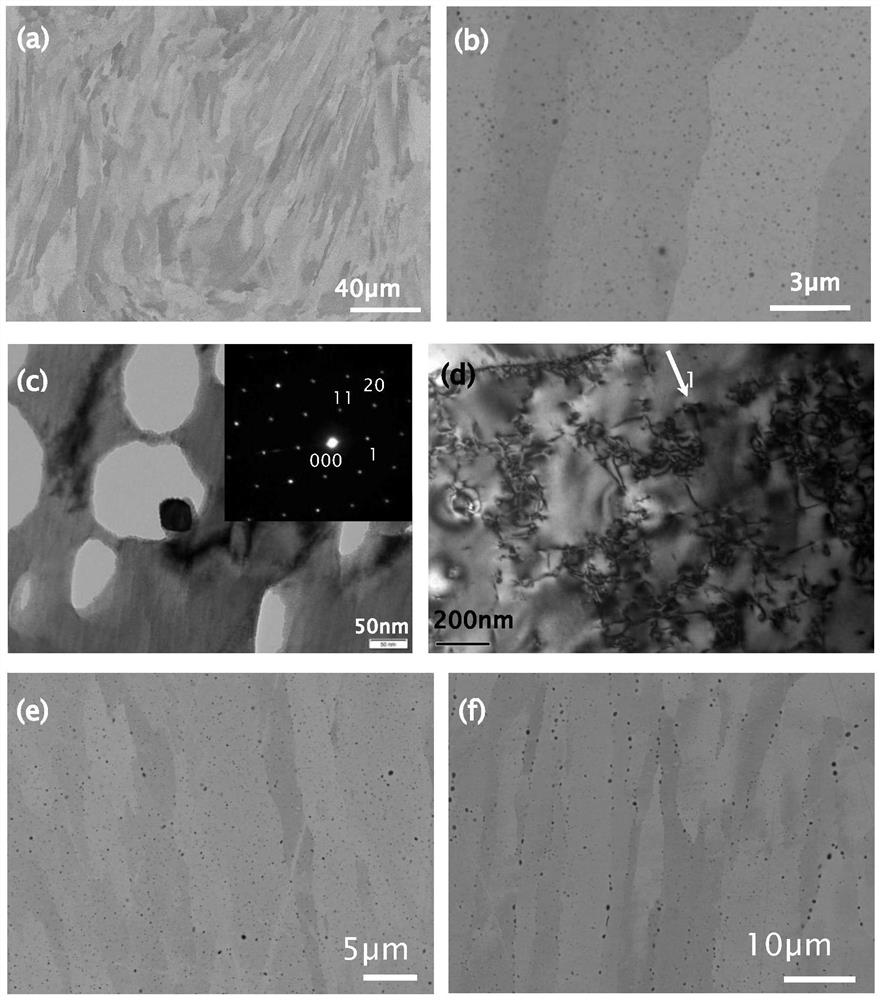

Image

Examples

Embodiment Construction

[0028] The following will clearly and completely describe the technical solutions in the embodiments of the present application with reference to the accompanying drawings in the embodiments of the present application. Obviously, the described embodiments are only for illustration, and are not intended to limit the present application.

[0029] The invention discloses a method for in-situ synthesis of a nano-oxide particle dispersion-strengthened alloy, which specifically includes the following steps:

[0030] For the convenience of description, the Fe-Ni alloy (Invar36) will be described below.

[0031] Step (1): Alloy design, so that the alloy contains elements that can form oxides.

[0032] The Invar36 designed in this example is a special low-expansion iron-nickel alloy with an ultra-low expansion coefficient. The chemical composition is (in weight%): 36wt.% Ni, 64wt.% Fe. Compared with Ni, Fe is a stronger oxide-forming element. In the present invention, by designing th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com