Method for reinforced 7075 aluminum alloy rolled sheets

A technology of aluminum alloy and aluminum alloy melt, applied in the field of strengthening 7075 aluminum alloy rolling sheet, can solve the problems of reducing fracture toughness, melt stress concentration, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

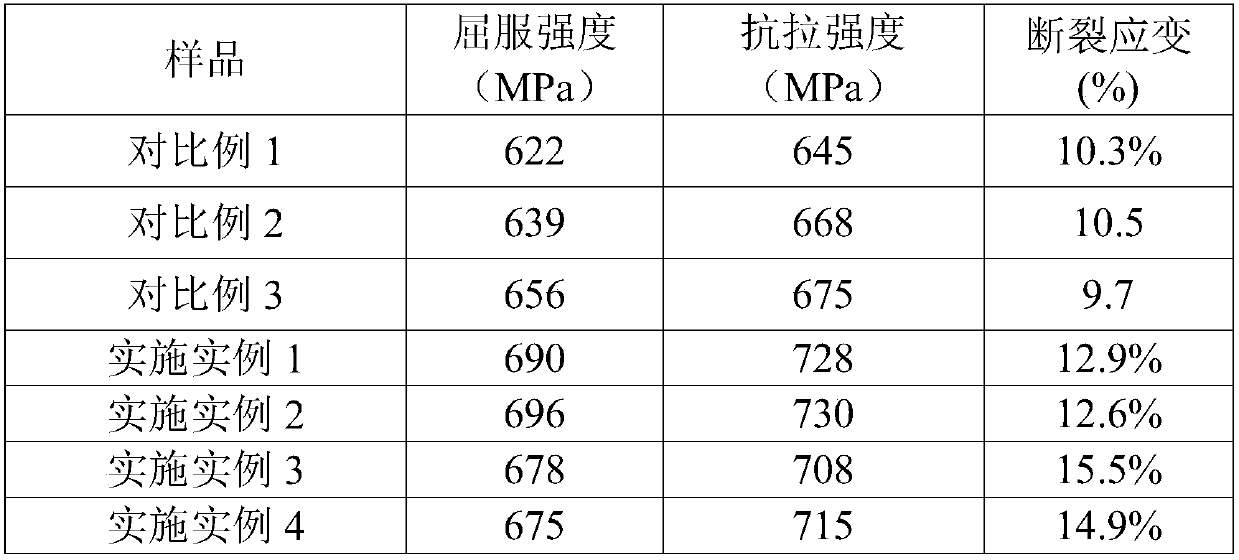

Examples

Embodiment 1

[0136] A kind of method of strengthening 7075 aluminum alloy rolled plate of this example is as follows:

[0137] Step 1, in situ reaction to prepare the aluminum alloy strengthening agent, specifically as follows:

[0138] (1) Preparation of Al-Ti-B 4 C-BN system reaction compact

[0139] (a) Weigh B at a molar ratio of 1:1 4 C powder and BN powder are ready for use. B 4 The particle size of C powder is 6.5 μm, and the purity is ≥92.0wt.%; the particle size of BN powder is 0.5 μm, and the purity is ≥99.0wt.%. 4 C and BN powders were activated by planetary ball mill at a speed of 200r / min for 3h.

[0140] (b) expected in Al-Ti-B 4 TiCN-AlN-TiB obtained in C-BN system 2 The mass fraction of ceramic particles is 40wt.%; in the reaction system Ti:B 4 The molar ratio of C:BN is 9:2.8:2.8; weigh Al powder, Ti powder, activated B 4 C powder and BN powder are ready for use. The particle size of the aluminum powder is 48 μm, and the purity is ≥99.9wt.%; the particle size of ...

Embodiment 2

[0170] A kind of method of strengthening 7075 aluminum alloy rolled plate of this example is as follows:

[0171] Step 1, in situ reaction to prepare the aluminum alloy strengthening agent, specifically as follows:

[0172] (1) Preparation of Al-Ti-B 4 C-BN system reaction compact

[0173] (a) Weigh B at a molar ratio of 1:1 4 C powder and BN powder are ready for use. B 4 The particle size of C powder is 2.6 μm, and the purity is ≥92.0wt.%; the particle size of BN powder is 1.3 μm, and the purity is ≥99.0wt.%. 4 C and BN powders were activated by planetary ball mill at a speed of 250r / min for 2h.

[0174] (b) expected in Al-Ti-B 4 TiCN-AlN-TiB obtained in C-BN system 2 The mass fraction of ceramic particles is 30wt.%; in the reaction system Ti:B 4 The molar ratio of C:BN is 9:2.8:2.8; weigh Al powder, Ti powder, activated B 4 C powder and BN powder are ready for use. The particle size of the aluminum powder is 38 μm, and the purity is ≥99.9wt.%; the particle size of ...

Embodiment 3

[0204] A kind of method of strengthening 7075 aluminum alloy rolled plate of this example is as follows:

[0205] Step 1, in situ reaction to prepare the aluminum alloy strengthening agent, specifically as follows:

[0206] (1) Preparation of Al-Ti-B 4 C-BN system reaction compact

[0207] (a) Weigh B at a molar ratio of 1:1 4 C powder and BN powder are ready for use. B 4 The particle size of C powder is 6.5 μm, and the purity is ≥92.0wt.%; the particle size of BN powder is 0.5 μm, and the purity is ≥99.0wt.%. 4 C and BN powders were activated by planetary ball mill at a speed of 250r / min for 2h.

[0208] (b) expected in Al-Ti-B 4 TiCN-AlN-TiB obtained in C-BN system 2 The mass fraction of ceramic particles is 30wt.%; in the reaction system Ti:B 4 The molar ratio of C:BN is 9:2.4:2.4; weigh Al powder, Ti powder, activated B 4 C powder and BN powder are ready for use. The particle size of the aluminum powder is 25 μm, and the purity is ≥99.9wt.%; the particle size of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| fracture strain | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com