Large-grain UO2 ceramic fuel, and preparation method and application thereof

A large-grain, ceramic technology, which is applied in the field of large-grain UO2 ceramic fuel and its preparation, can solve the problems of low thermal conductivity, swelling suppression and deepening fuel consumption, achieve low thermal expansion coefficient, improve economy and safety, The effect of reducing the specific surface area of grain boundaries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The present invention provides a large grain UO 2 The preparation method of ceramic fuel comprises the following steps:

[0033] Will UO 2 Powder, additives and lubricants are mixed by ball milling to obtain mixed powder;

[0034] The mixed powder is sintered to obtain large grain UO 2 ceramic fuel;

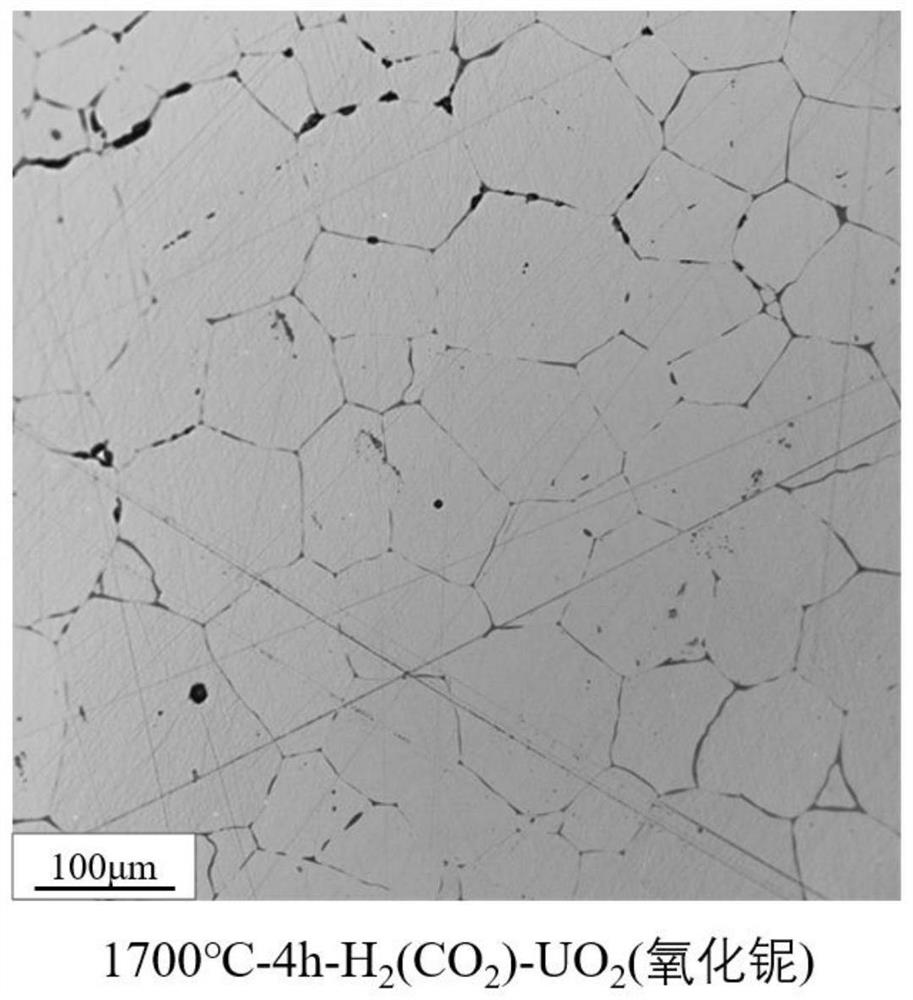

[0035] The additive includes metal oxide and / or metal element; the metal oxide includes one or more of manganese oxide, titanium oxide, niobium oxide, chromium oxide and vanadium oxide; the metal element includes niobium, chromium, One or more of manganese and vanadium;

[0036] The large grain UO 2 The average grain size of the ceramic fuel is 50-180 μm.

[0037] In the present invention, unless otherwise specified, the required preparation materials are commercially available products well known to those skilled in the art.

[0038] The present invention will UO 2 The powder, additive and lubricant are ball milled and mixed to obtain a mixed powder. In the prese...

Embodiment 1

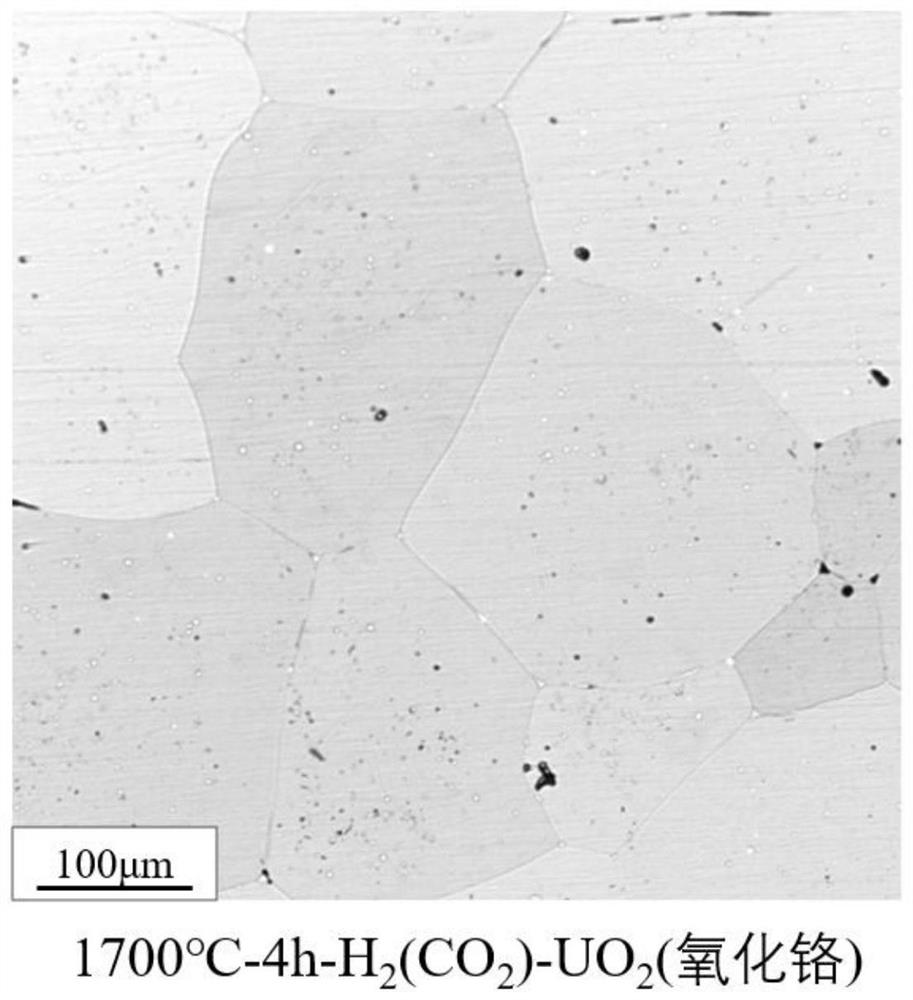

[0062] 100gUO 2 Powder, 0.5g chromium oxide powder (particle size 5 ~ 10μm, the amount added accounted for UO 2 The mass fraction is 0.5%) and 0.3g Akewax are placed in a tungsten carbide ball mill jar, and zirconia grinding balls with 3 times the mass of the resulting mixture are added, and mixed for 16 hours to obtain a mixed powder;

[0063] Weigh 7g of the above mixed powder and mold it, the pressing pressure is 200MPa, to get UO 2 For the green body, use an atmosphere sintering furnace to carry out pressureless sintering on the green body, vacuumize the atmosphere sintering furnace and fill it with argon atmosphere protection, raise the temperature to 800°C at a rate of 10°C / min and keep it for 1h for degreasing, and continue to pass through The mixed gas of hydrogen and carbon dioxide (the volume ratio of carbon dioxide is 1.8%) is brought to normal pressure, the temperature is raised to 1700°C at a rate of 5°C / min and kept for 4h, and then cooled to room temperature wi...

Embodiment 2

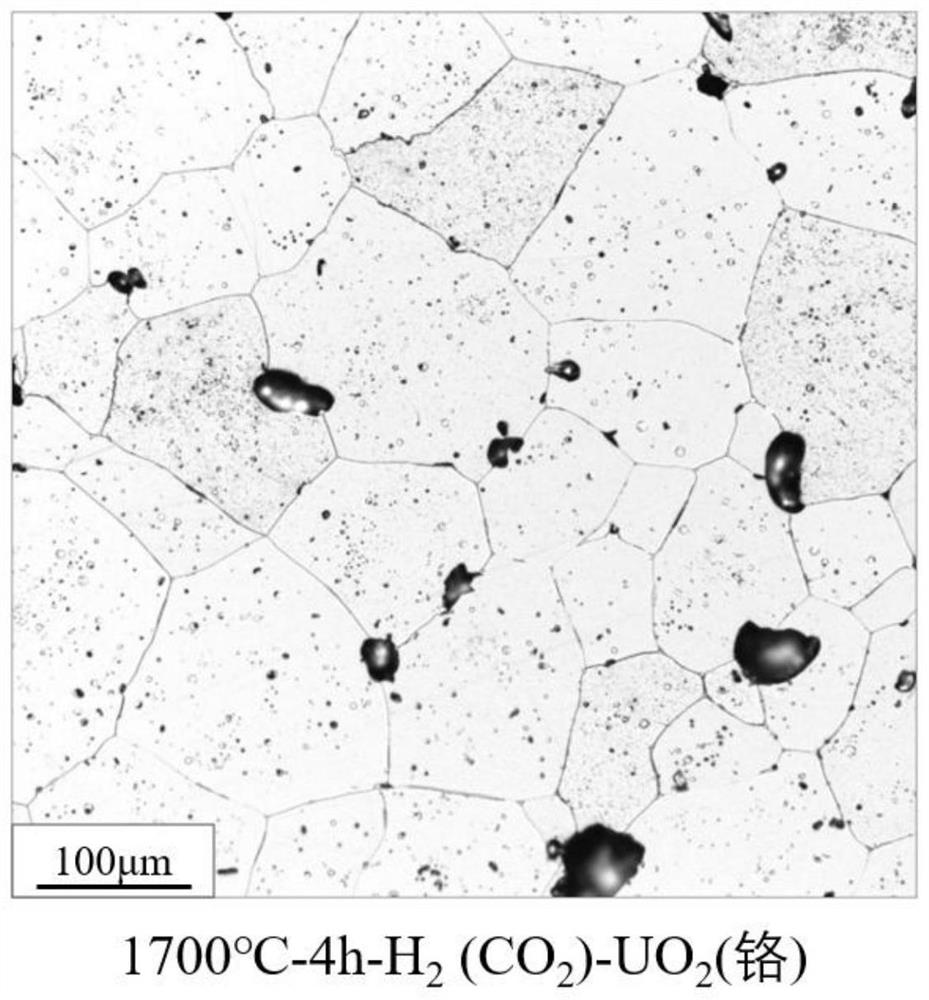

[0065] The difference with Example 1 is only: the additive is chromium powder (10~30 μ m in particle size, and the addition accounts for 10 2 The massfraction of is 0.5%), others are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com