Novel nickel-chromium-iron electrothermal alloy

An electrothermal alloy, nickel-chromium-iron technology, applied in the field of new-type nickel-chromium-iron electrothermal alloy, can solve the problems of high price, high nickel content, and application field restrictions, and achieve low price, low density, improved high temperature creep performance and resistance Oxidative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

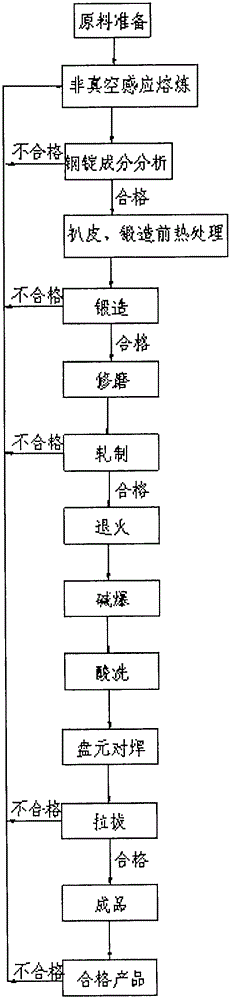

Image

Examples

Embodiment 1

[0021] The invention provides a technical solution: a novel nickel-chromium-iron electric heating alloy, which is made of the following raw materials in various mass percentages: Si: 0.7%, Mn: 0.3%, Cr: 20%, Ni: 41%, and the rest The amount is iron and unavoidable trace elements; the weight percentage of unavoidable trace elements is 0.05%.

[0022] In this embodiment, a variety of rare trace elements, including cobalt, niobium, aluminum, molybdenum, rhenium, titanium, and yttrium, are added to the raw materials, which can improve the high-temperature creep performance and oxidation resistance of the nickel-chromium-iron electric heating alloy.

[0023] The preparation method of the present embodiment comprises the following steps:

[0024] A. Prepare and mix all the raw materials and put them into a non-vacuum induction melting furnace for vacuum induction melting. The melting temperature is 1580°C and the refining time is 30 minutes;

[0025] B. Analyze the composition of t...

Embodiment 2

[0032] The invention provides a technical solution: a novel nickel-chromium-iron electric heating alloy, which is made of the following raw materials in various mass percentages: Si: 1.6%, Mn: 0.6%, Cr: 23%, Ni: 43%, and the rest The amount is iron and unavoidable trace elements; the weight percent content of unavoidable trace elements is 0.06%.

[0033] In this embodiment, a variety of rare trace elements, including cobalt, niobium, aluminum, molybdenum, rhenium, titanium, and yttrium, are added to the raw materials, which can improve the high-temperature creep performance and oxidation resistance of the nickel-chromium-iron electric heating alloy.

[0034] The preparation method of the present embodiment comprises the following steps:

[0035] A. Prepare and mix all the raw materials and put them into a non-vacuum induction melting furnace for vacuum induction melting. The melting temperature is 1520°C and the refining time is 20 minutes;

[0036] B. Analyze the composition...

Embodiment 3

[0043] The invention provides a technical solution: a novel nickel-chromium-iron electric heating alloy, which is made of the following raw materials in various mass percentages: Si: 0.9%, Mn: 0.4%, Cr: 21%, Ni: 42%, and the rest The amount is iron and unavoidable trace elements; the weight percentage of unavoidable trace elements is 0.1%.

[0044] In this embodiment, a variety of rare trace elements, including cobalt, niobium, aluminum, molybdenum, rhenium, titanium, and yttrium, are added to the raw materials, which can improve the high-temperature creep performance and oxidation resistance of the nickel-chromium-iron electric heating alloy.

[0045] The preparation method of the present embodiment comprises the following steps:

[0046] A. Prepare and mix all the raw materials and put them into a non-vacuum induction melting furnace for vacuum induction melting. The melting temperature is 1540°C and the refining time is 25 minutes;

[0047] B. Analyze the composition of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com