Copper alloy material and preparation method and application thereof

A copper alloy and bar technology, applied in the field of additive manufacturing, can solve the problems of poor high temperature mechanical properties, high temperature creep, cooling channel degradation and failure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The present invention also provides a preparation method for the copper alloy material described in the above technical solution, comprising the following steps:

[0036] Mixing Cu source, Cr source, Nb source, Zr source, Ag source and RE source, followed by vacuum induction melting and casting to obtain copper alloy rods;

[0037] After machining the copper alloy rod, a copper alloy electrode rod is obtained;

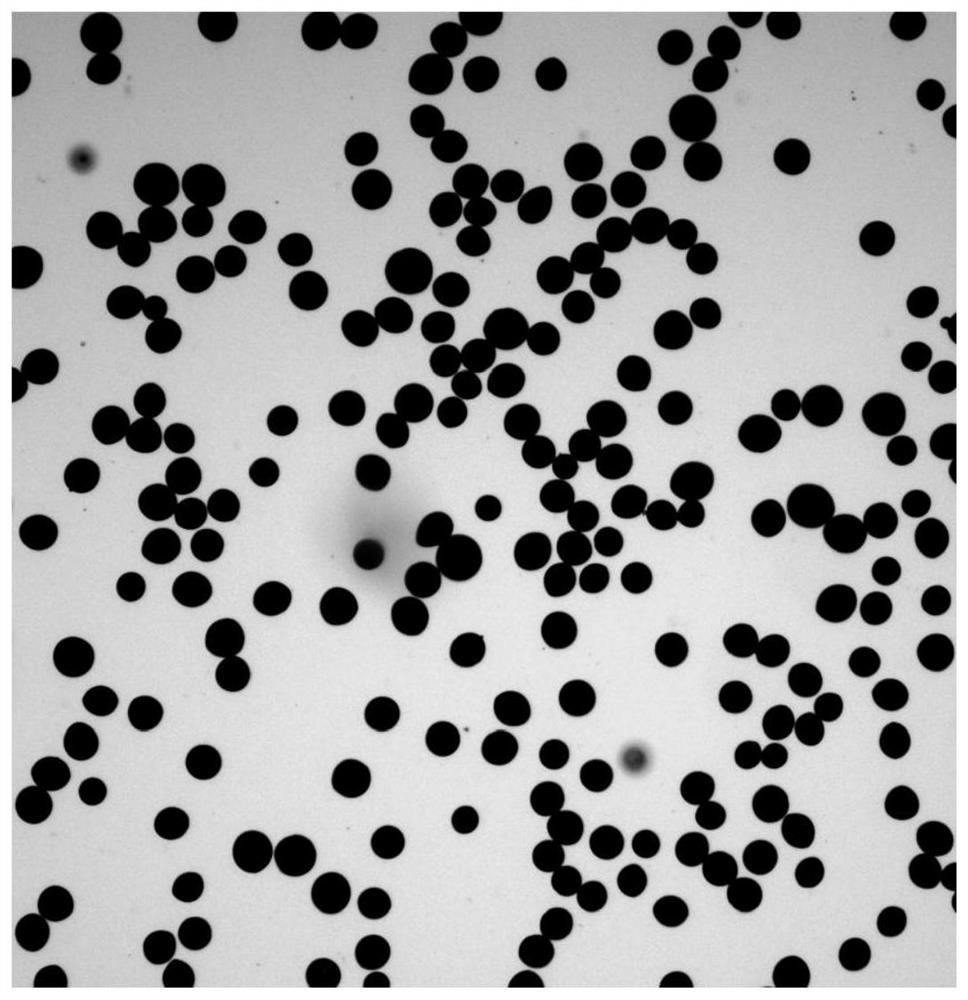

[0038] Using the copper alloy electrode rod as an anode, conduct plasma spheroidization rotating electrode atomization under vacuum and protective atmosphere to obtain the copper alloy material.

[0039] In the invention, Cu matrix, Cr, Nb, Zr, Ag and RE alloy elements are mixed, followed by vacuum induction melting and pouring to obtain copper alloy rods.

[0040] In the present invention, the Cu matrix is preferably electrolytic copper, and the present invention has no special limitation on the source of the electrolysis, which can be produced by convention...

Embodiment 1~8

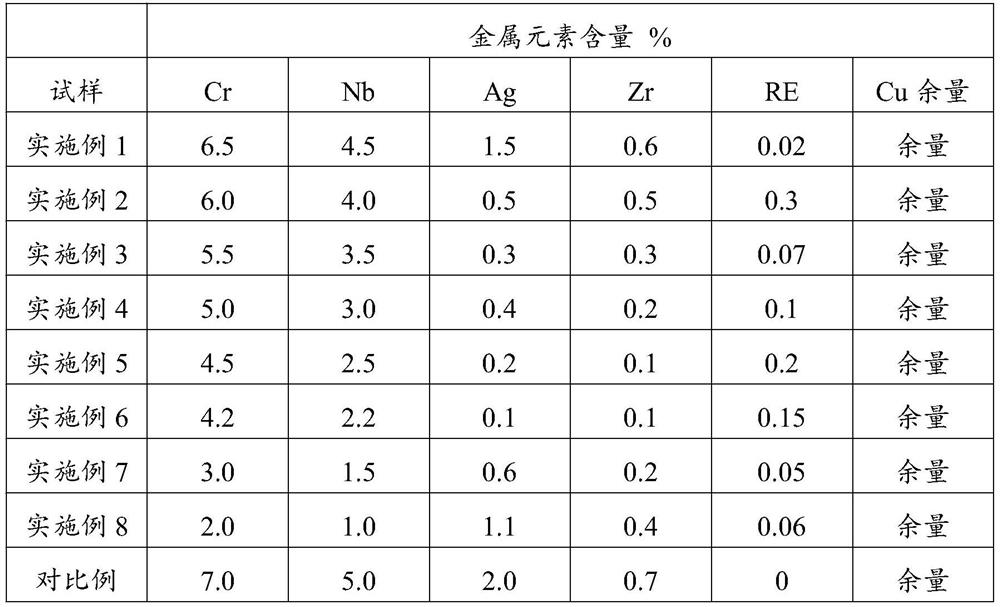

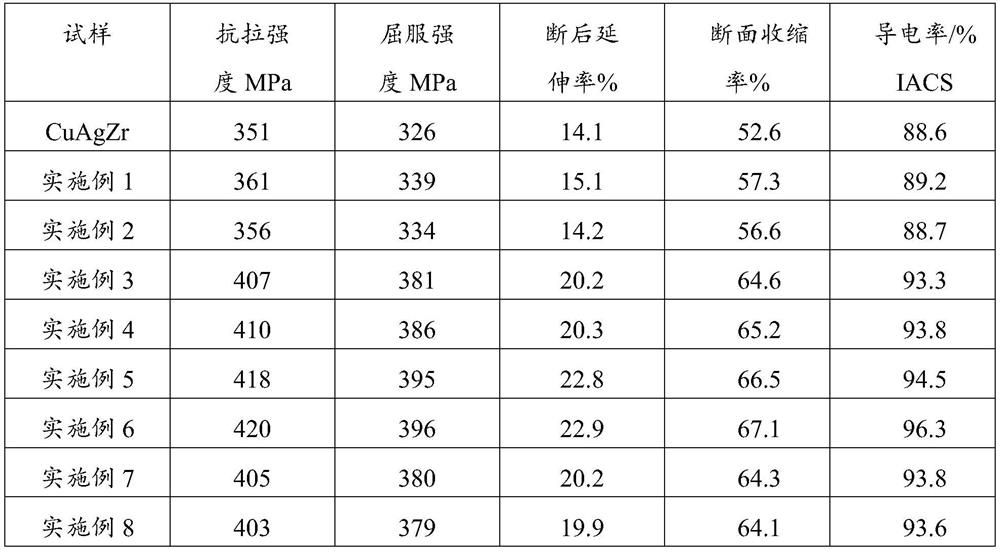

[0060] According to the mass percentage ratio of each metal element in the copper alloy material (see Table 1 for specific content), weigh electrolytic copper powder, CuCr alloy powder (Cu70%-Cr30%), CuNb alloy powder (Cu80%-Nb20%), CuZr alloy powder (Cu85%-Zr15%), industrial pure Ag powder, RE alloy powder (La90%-Ce8%-Pr1.7%-Nd0.3%), add the above powder into the vacuum induction furnace;

[0061] After evacuating the vacuum induction furnace to 0.01Pa, fill it with an inert gas (mixed gas of argon and helium, the volume ratio is 1:1), raise the temperature from room temperature to 1250°C at 10°C / min, and keep it warm for 10min; 7°C / min, heat up from 1250°C to 1300°C, hold for 8 minutes; at 7°C / min, heat up from 1300°C to 1550°C, conduct vacuum induction melting to obtain melt, cast the melt to obtain copper alloy rods, Diameter 55~85mm, length 900~1300mm;

[0062] Using a lathe to remove the skin of the copper alloy rod to a depth of 1-2 mm from the prepared copper alloy ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com