Cold-pressed steel plate for automotive axle housing and production method thereof

A production method and axle housing technology, applied in the field of iron and steel smelting technology, can solve problems affecting vehicle safety, high scrap rate, inconsistent product quality, etc., and achieve the effect of improving cold forming performance and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] C: 0.15%, Si: 0.4%, Mn: 1.5%, P≤0.015%, S≤0.005%, V: 0.05%, Nb: 0.02%, Als: 0.04%, the balance is Fe and a small amount of impurities.

Embodiment 2

[0045] C: 0.16%, Si: 0.45%, Mn: 1.60%, P≤0.015%, S≤0.005%, V: 0.060%, Nb: 0.030%, Als: 0.050%, the balance is Fe and a small amount of impurities.

Embodiment 3

[0047] C: 0.10%, Si: 0.30%, Mn: 1.45%, P≤0.015%, S≤0.005%, V: 0.045%, Nb: 0.015%, Als: 0.025%, the balance is Fe and a small amount of impurities.

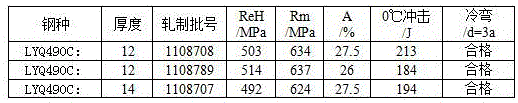

[0048] Embodiments 1 to 3 are all produced by the above method. Embodiment 1 to 3 steel detection data are as follows:

[0049]

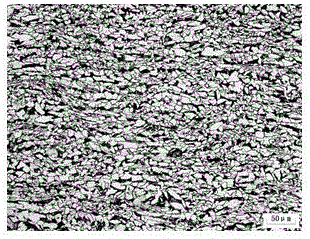

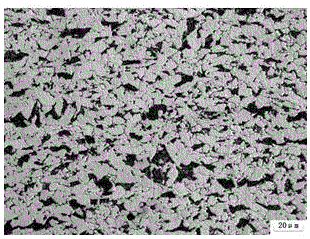

[0050]Through the above form and figure 1 , 2 The above-mentioned steel materials shown above all meet the 600MPa steel standard for automobile axle housings, and the tensile, impact and other mechanical properties of steel plates, ultrasonic flaw detection and other indicators are superior to similar products, and meet the production requirements of automobile axle housing manufacturers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com