Floatation separation method for mengite and hamartite in misch metal ore concentrate

A bastnaesite and mixed rare earth technology, applied in flotation, solid separation, etc., can solve the problems of fluorine pollution, unresearched smelting of mixed rare earth ore with high monazite, etc., and achieve the effect of short process flow and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

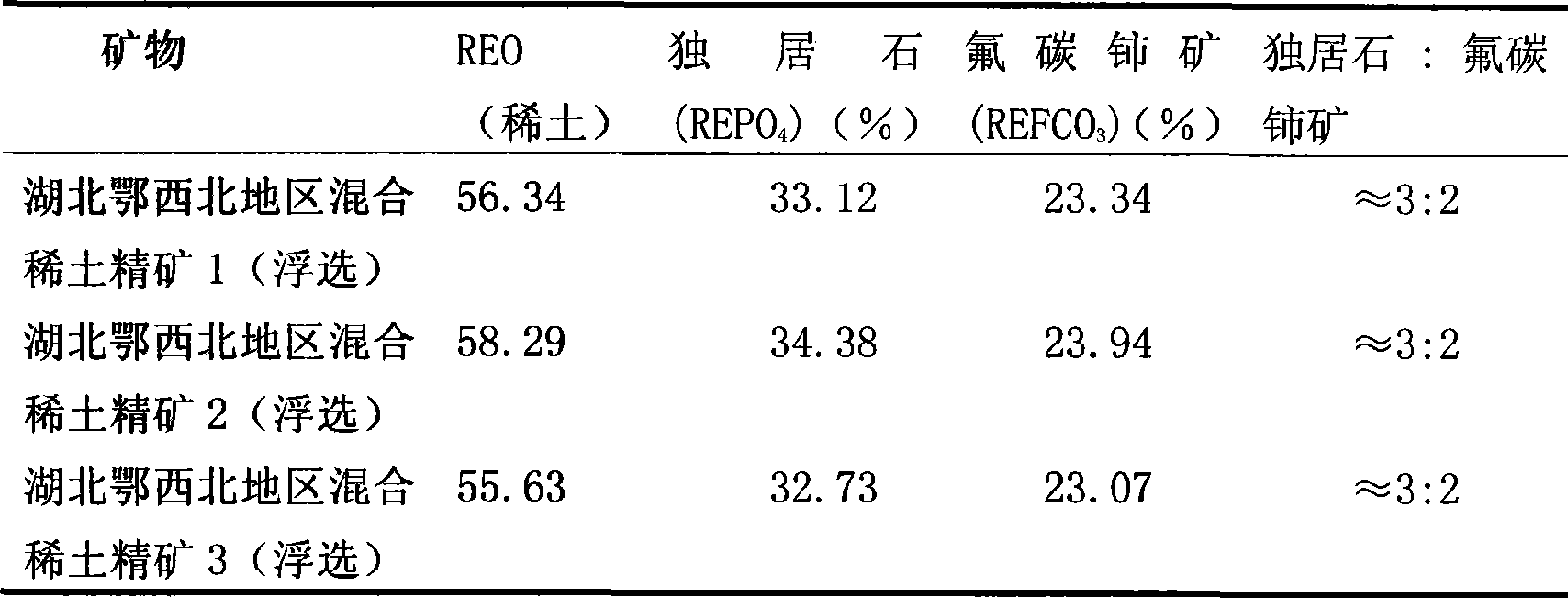

Embodiment 1

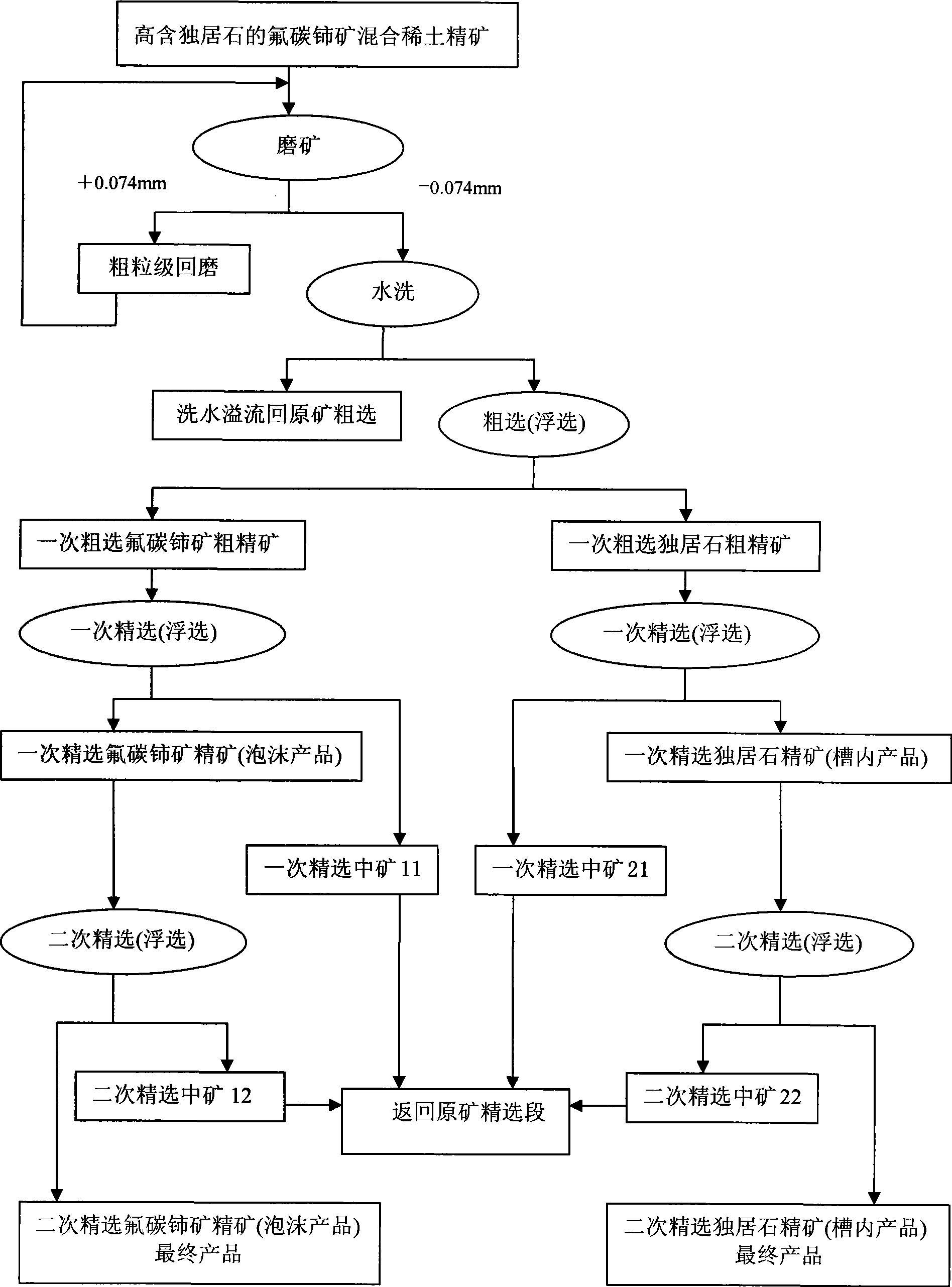

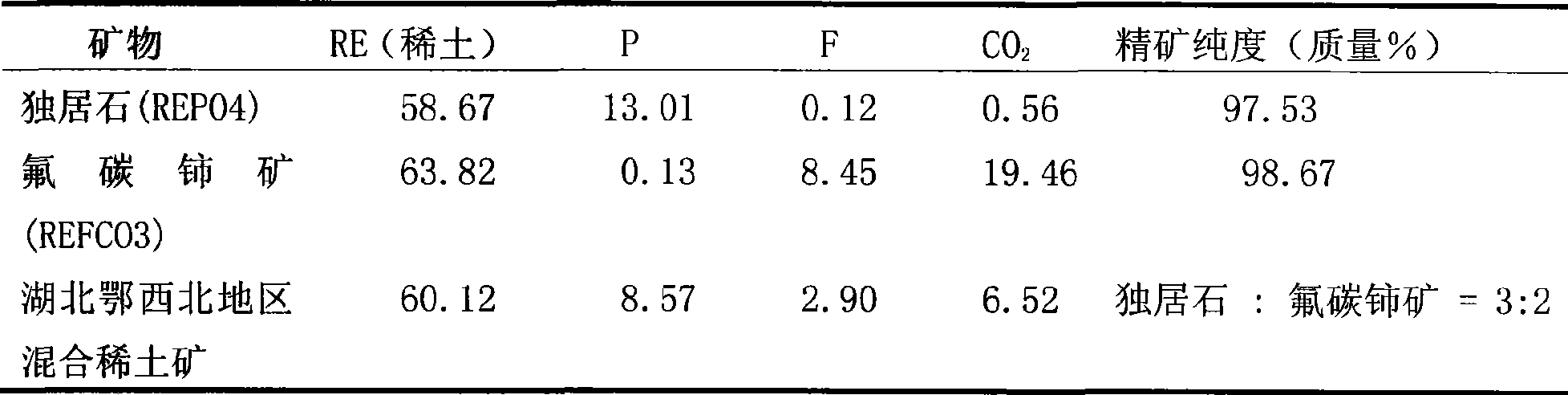

[0039] One, the preparation method (flotation separation) of the bastnaesite mixed rare earth concentrate containing high monazite, it comprises the steps:

[0040] 1) Grinding: Select the mixed rare earth ore in the northwest of Hubei Province (called bastnaesite mixed rare earth ore with high monazite content, also known as raw ore), and the REO content of the raw ore grade is 1.68%; The bastnaesite mixed rare earth ore is ground into ore powder, and in the ore powder, the bastnaesite mixed rare earth ore with a particle size of -0.074mm accounts for 95% by mass ("-" means less than, and the present invention includes equal to 0.074mm);

[0041] 2) Rough separation: add water to the ore powder for mixing and stirring to obtain ore pulp; wherein the quality of water added is ore powder: water=1:1.3 (that is, the mass concentration of the pulp is 44%); the pulp after the slurry processing is sent to Enter the flotation unit, and add 0.5 kilogram of water glass depressant, 1.2...

Embodiment 2

[0054] One, the preparation method (flotation separation) of the bastnaesite mixed rare earth concentrate containing high monazite, it comprises the steps:

[0055] 1) Grinding: Select the mixed rare earth ore in the northwest of Hubei Province (called bastnaesite mixed rare earth ore with high monazite content, also known as raw ore), the raw ore grade REO content is 1.45%; The bastnaesite mixed rare earth ore is ground into ore powder, and in the ore powder, the bastnaesite mixed rare earth ore with a particle size of -0.074mm accounts for 95% by mass ("-" means less than, and the present invention includes equal to 0.074mm);

[0056] 2) Rough separation: add water to the ore powder for mixing and stirring to obtain ore pulp; wherein the quality of water added is ore powder: water=1:1.4 (that is, the mass concentration of the pulp is 42%); the pulp after the slurry processing is sent to Enter the flotation unit, and add 1.2 kilograms of water glass inhibitors, 1.6 kilograms...

Embodiment 3

[0069] One, the preparation method (flotation separation) of the bastnaesite mixed rare earth concentrate containing high monazite, it comprises the steps:

[0070] 1) Grinding: Select the mixed rare earth ore in the northwest of Hubei Province (called bastnaesite mixed rare earth ore with high monazite content, also known as raw ore), the raw ore grade REO content is 1.83%; The bastnaesite mixed rare earth ore is ground into ore powder, and in the ore powder, the bastnaesite mixed rare earth ore with a particle size of -0.074mm accounts for 95% by mass ("-" means less than, and the present invention includes equal to 0.074mm);

[0071] 2) Rough separation: add water to the ore powder and mix and stir to obtain the slurry; wherein the quality of adding water is ore powder: water=1:1.3 (that is, the mass concentration of the slurry is 44%); the slurry after the slurry treatment is sent to Enter the flotation device, and add 0.7 kilograms of water glass, 1.5 kilograms of collec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com