Mg alloys containing misch metal, manufacturing method of wrought mg alloys containing misch metal, and wrought mg alloys thereby

A technology of mixed rare earth and rare earth alloys, which is applied in the fields of telephone communication, electrical components, branch equipment, etc., can solve the problems of restricting grain refinement, grain refinement restriction, and thickness reduction restriction, etc., and achieves excellent formability. , high mechanical properties, improved formability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0046] The magnesium alloy containing mischmetal according to the present invention has Mg 100-x-y-z A x B y C z The formula expressed, wherein A is zinc (Zn) or aluminum (Al); B is misch; C is selected from manganese (Mn), nickel (Ni), copper (Cu), tin (Sn), yttrium (Y ), phosphorus (P), silver (Ag) and strontium (Sr) at least one element; and x, y and z satisfy 0 atomic % ≤ x ≤ 6 atomic %, 0.8 atomic % ≤ y ≤ 7 atomic % and a composition of 0 atomic % ≤ z ≤ 2 atomic %.

[0047] When the mischmetal-containing magnesium alloy according to the invention is solidified by casting, the magnesium-rich solid solution (α-magnesium) constitutes the matrix structure. The second phase is crystallized by mixed rare earth (element B) to form a network structure or dispersed phase composited with the magnesium matrix. The network structure is stable at high temperatures, thereby providing excellent mechanical properties. In addition, group A and group C elements can generate a tertiar...

Embodiment 1

[0057] Molten metals of the magnesium alloy compositions given in Table 1 below were prepared and castings were obtained by casting. More specifically, the graphite crucible was heated at a temperature of 700° C. in an induction furnace. Magnesium is melted in this graphite crucible, and then other additives are added. This forms a molten alloy, which is poured into a mold preheated to 1200°C. This forms the casting.

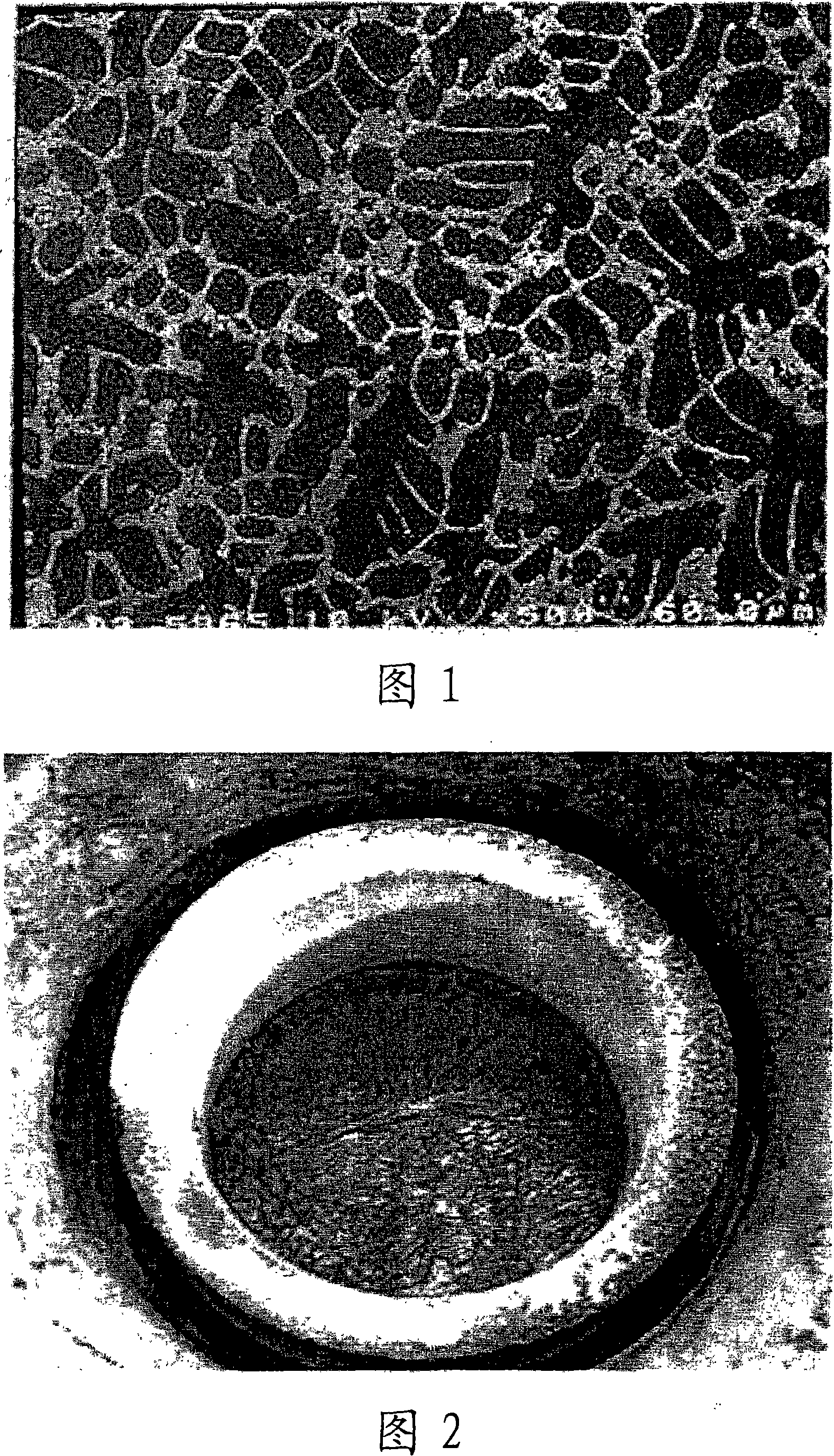

[0058] In the compositions specified in Table 1, B refers to cerium-based misch metal in atomic %. The second phase generated by the addition of element B is Mg 12 Ce phase. Figure 1 is a scanning electron micrograph of alloy 3, showing the α-magnesium structure and Mg 12 The Ce phase forms a network structure. Since the structure forming the network structure is stable at high temperature, deformation of the α magnesium structure can be suppressed, so they exhibit high strength at high temperature. Therefore, as the amount of B element increases, Mg 12 ...

Embodiment 2

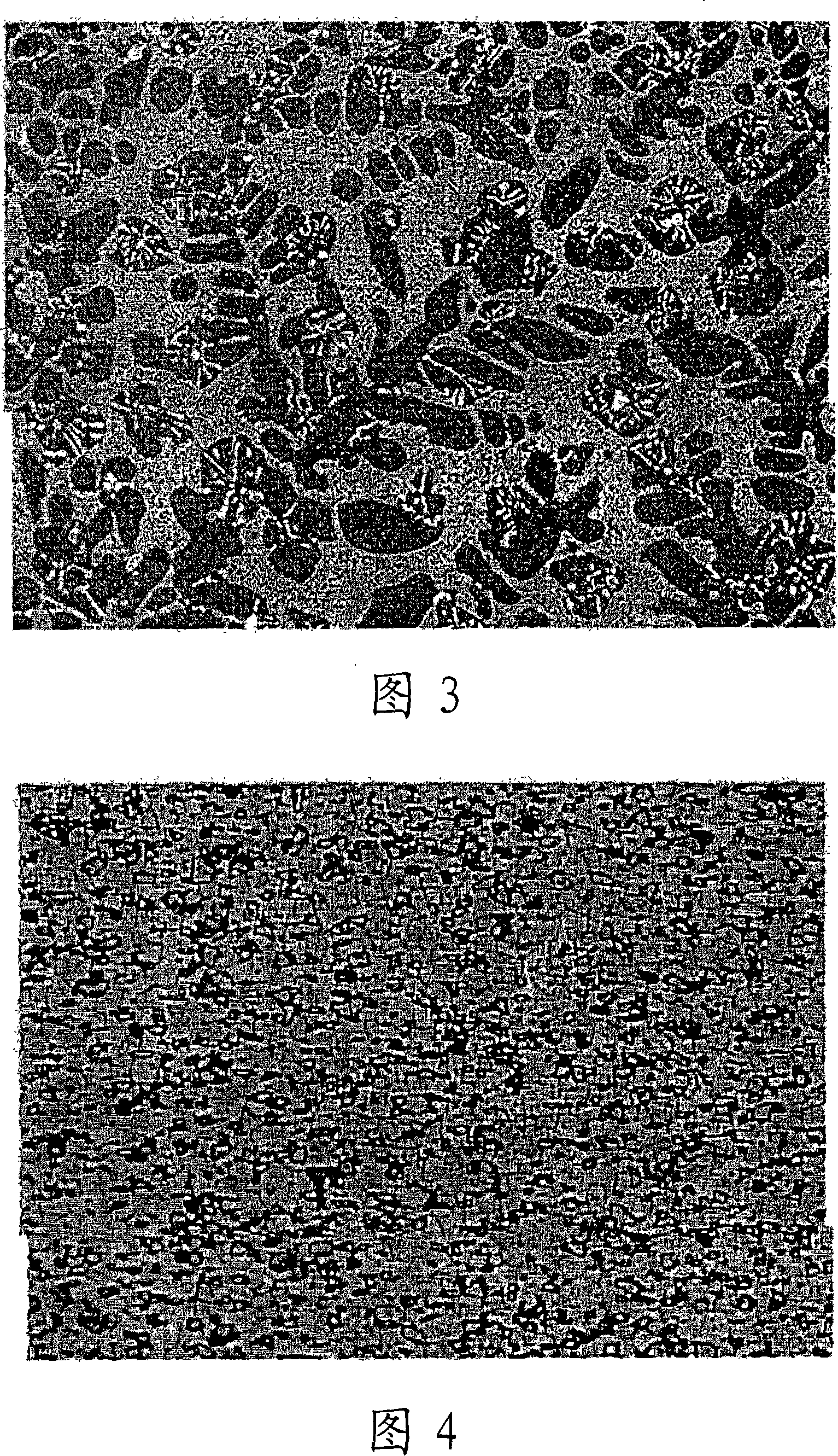

[0068] Figure 2 is a photograph of a molten metal in which 2% by weight of calcium (Ca) was added to Alloy 9 listed in Table 1 and melted in air, showing that by adding calcium (Ca) to a magnesium alloy composition (such as Alloy 9), ) after which the magnesium alloy composition can be melted and cast in air. As can be seen from FIG. 2, when the magnesium alloy composition was melted in air, it was found that no thick oxide was formed on the surface of the molten metal.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com