Heat resisting low expansion silumin and preparation thereof

A high-silicon aluminum alloy and low-expansion technology, which is applied in the field of non-ferrous metal materials and their preparation and forming, can solve the problems of few practical applications, difficult adaptation of aluminum alloys, and many research results, and achieve the goal of improving comprehensive performance and good wear resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

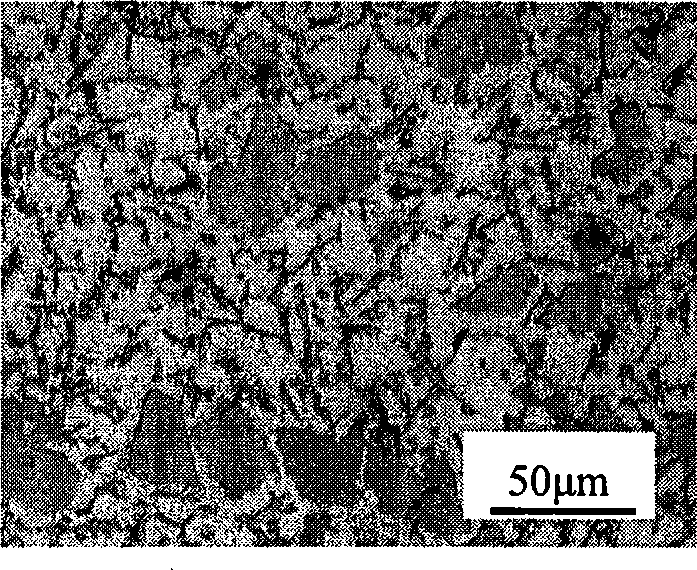

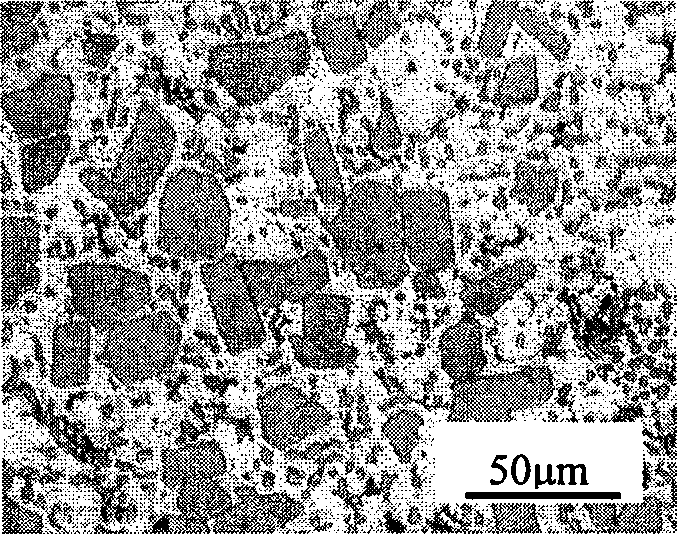

Image

Examples

preparation example Construction

[0028] The preparation of the heat-resistant low-expansion high-silicon aluminum alloy includes two processes of smelting and modification. Materials of Si, Mn, RE, and phosphorus elements usually use their intermediate alloys. Si is usually made of aluminum-silicon master alloy, or industrial pure aluminum ingot plus crystalline silicon, Mn is made of aluminum-manganese master alloy, RE is made of aluminum-rare-earth master alloy, and phosphorus element is made of phosphor-copper master alloy. Before starting the preparation, the raw materials are prepared according to the above mass percentages for use. Due to the need for metamorphic treatment during the preparation process, a large amount of P will be burned during the metamorphic treatment process, so P should be added in excess, that is, the amount of phosphorus added is 0.04 to 0.1% of the total weight of the raw materials, so that the prepared high-silicon aluminum The actual content of P in the alloy is 0.006-0.04%. ...

Embodiment 1

[0033] Put No. A00 pure Al, 99.9% (mass fraction, the same below) pure Ni, 99.99% pure Cu, and Al-25.8% Si master alloy into the melting furnace to melt it into an aluminum-silicon alloy melt. Then the alloy melt is superheated to 850°C, and Al-10%Mn master alloy is added. Then heat to dissolve and stir evenly to obtain a mixed melt; after that, adjust the melt temperature to 780°C and add 99.9% pure Mg, and the obtained alloy composition is Al-20Si-2Cu-1Ni-0.4Mg-0.5Mn-1.0RE -0.01P, the rest is Al. Add Al-15% RE master alloy after melting, the content of Ce in RE is 50%, so that the final RE content of the aluminum alloy is 1.0%, which mainly plays the role of eutectic Si modification. Refining the melt with pure Ar gas at 820°C, removing slag, and standing for 10 minutes. Phosphor-bronze master alloy is added to modify the primary crystal Si, and the amount of P added is 0.06% of the total weight of the raw material, so that the final content of P is about 0.01%. Keep warm...

Embodiment 2

[0035] Put No. A00 pure Al, No. 1 crystalline silicon, 99.9% (mass fraction, the same below) pure Ni, and 99.99% pure Cu into the smelting furnace to melt it into an aluminum-silicon alloy melt. Then the alloy melt is superheated to 870°C, and Al-10%Mn master alloy is added. Then heat to dissolve and stir evenly to obtain a mixed melt; after that, adjust the melt temperature to 800°C and add 99.9% pure Mg, melt in a crucible resistance furnace, and prepare the alloy composition as Al-25Si-2.5Cu-0.5Ni- 0.8Mg-0.6Mn-0.8RE-0.04P, the rest is Al. Al-10% RE is added after melting, and the Ce content in RE is 65%, so that the final RE content of the aluminum alloy is 0.8%, which mainly plays the role of eutectic Si modification. Refining the melt with pure Ar gas at 820°C, removing slag, and standing for 10 minutes. Phosphor-bronze master alloy is added to modify the primary crystal Si, and the amount of P added is 0.10% of the total weight of the raw material, so that the final co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com