Sn-Ag-Cu misch metal lead-free solder with low content of Cu and preparation method thereof

A mixed rare earth, lead-free solder technology, applied in the direction of manufacturing tools, welding equipment, metal processing equipment, etc., can solve the problems of high cost of solder, increase of Ag3Sn intermetallic compounds, increase of cost of solder, etc., and achieve high oxidation resistance. Performance and anti-corrosion performance, improve anti-oxidation ability and wettability, reduce the effect of equipment renovation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

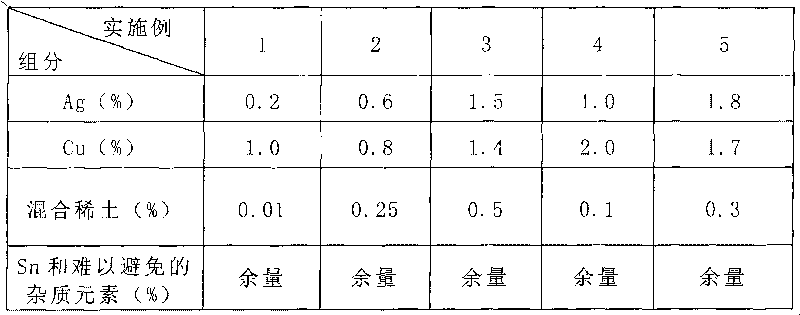

Embodiment 1

[0030]Add the mixed salt of potassium chloride:potassium oxide=(1~1.7):(0.8~1.3)(weight percent) into the furnace, after melting at 580°C, add 98.79% tin by weight; after the tin is completely melted, 0.2% by weight of Ag and 1.0% by weight of Cu are added to the tin liquid and stirred to form an alloy; at the same time, 0.01% by weight of La-Ce-based mixed rare earths is quickly added to the above alloy liquid and continuously stirred until Until the rare earth is completely melted; keep the temperature at 460°C for 1.5 hours and stir to homogenize the alloy. After cooling, remove the mixed salt of potassium chloride and potassium oxide on the surface after the alloy is solidified, and obtain the tin-silver-copper mixed rare earth lead-free solder with low silver content.

Embodiment 2

[0032] Add the mixed salt of potassium chloride:potassium oxide=(1~1.7):(0.8~1.3)(weight percent) into the furnace, after melting at 580°C, add 98.35% tin by weight; after the tin is completely melted, 0.6% by weight of Ag and 0.8% by weight of Cu are added to the tin liquid and stirred to form an alloy; at the same time, 0.25% by weight of La / Ce-based mixed rare earth is quickly added to the above alloy liquid and continuously stirred until Until the rare earth is completely melted; keep the temperature at 460°C for 1.5 hours and stir to homogenize the alloy. After cooling, remove the mixed salt of potassium chloride and potassium oxide on the surface after the alloy is solidified, and obtain the tin-silver-copper mixed rare earth lead-free solder with low silver content.

Embodiment 3

[0034] Add the mixed salt of potassium chloride:potassium oxide=(1~1.7):(0.8~1.3)(weight percent) into the melting furnace, after melting at 580°C, add 96.6% tin by weight; after the tin is completely melted, 1.5% by weight of Ag and 1.4% by weight of Cu are added to the tin liquid, stirred to form an alloy; at the same time, 0.5% by weight of La / Ce-based mixed rare earth is quickly added to the above alloy liquid, and continuously stirred until Until the rare earth is completely melted; keep the temperature at 460°C for 1.5 hours and stir to homogenize the alloy. After cooling, remove the mixed salt of potassium chloride and potassium oxide on the surface after the alloy is solidified, and obtain the tin-silver-copper mixed rare earth lead-free solder with low silver content.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com