A large-scale liquid-cooled pipe network and its welding method

A welding method and technology of liquid-cooled tubes, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve problems such as reducing the thickness of the cover plate, reducing welding heat input, welding deformation, and reducing the physical space on both sides of the weld , to achieve the effect of reducing welding heat input, reducing welding heat input and welding deformation, and reducing structural redundancy design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

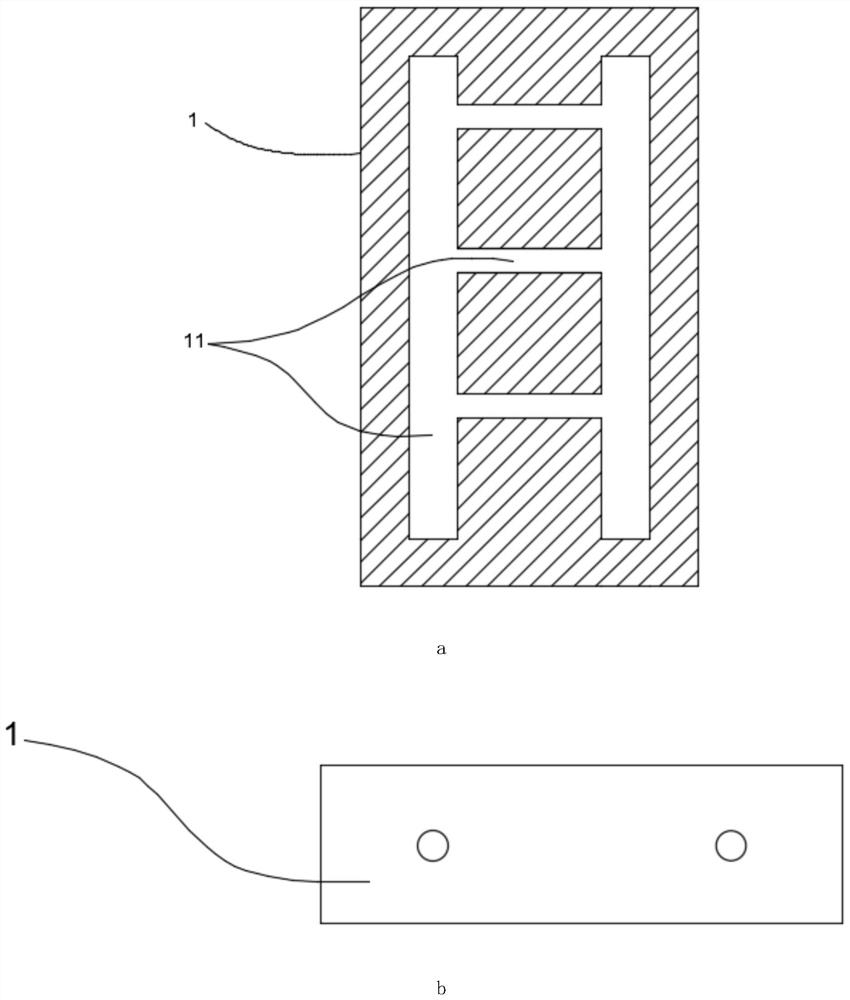

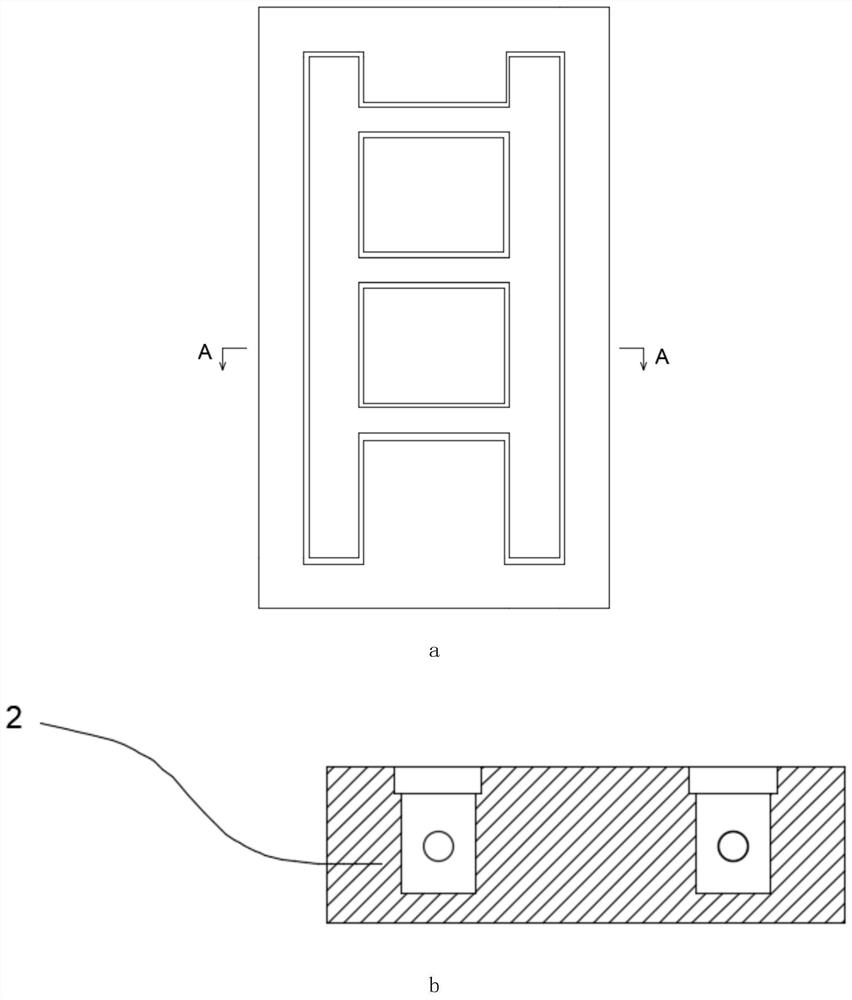

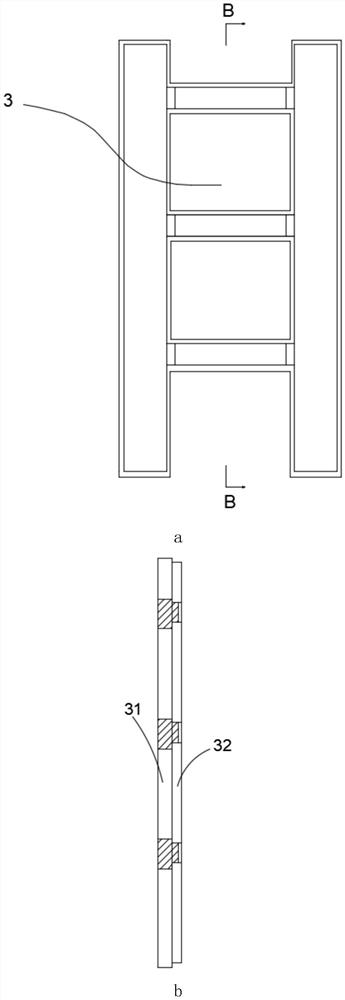

[0042] Such as Figure 1~5 As shown, this embodiment provides a large-scale liquid-cooled pipe network, including a liquid-cooled housing 2 and a stepped cover plate 3 , and the stepped cover plate 3 includes a welded stepped cover plate 31 and a reinforced stepped cover plate 32 . The thicknesses of the welded step cover plate 31 and the reinforced step cover plate 32 are respectively H 1 and H 2 . The width of the reinforced stepped cover plate 32 is equal to the width of the flow channel 11 of the large-scale liquid cooling pipe network 1, which can completely seal the upper opening of the flow channel 11, avoiding the loss and leakage of the heat exchange fluid, and ensuring the heat exchange and cooling performance.

[0043] The welded step cover plate 31 and the reinforced step cover plate 32 are integrally designed and processed.

[0044] The thicknesses of the welded step cover plate 31 and the reinforced step cover plate 32 are respectively H 1 and H 2, calculate...

Embodiment 2

[0057] Such as Figure 1~5 As shown, this embodiment provides a large-scale liquid-cooled pipe network, including a liquid-cooled housing 2 and a stepped cover plate 3 , and the stepped cover plate 3 includes a welded stepped cover plate 31 and a reinforced stepped cover plate 32 . The thicknesses of the welded step cover plate 31 and the reinforced step cover plate 32 are respectively H 1 and H 2 . The width of the reinforced stepped cover plate 32 is equal to the width of the flow channel 11 of the large-scale liquid cooling pipe network 1, which can completely seal the upper opening of the flow channel 11, avoiding the loss and leakage of the heat exchange fluid, and ensuring the heat exchange and cooling performance.

[0058] The welded step cover plate 31 and the reinforced step cover plate 32 are integrally designed and processed.

[0059] The thicknesses of the welded step cover plate 31 and the reinforced step cover plate 32 are respectively H 1 and H 2 , calculat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com