UHPC-SS (Ultra High Performance Concrete) composite pipeline and manufacturing method thereof

A UHPC-SS composite pipeline technology, applied in the field of UHPC-SS composite pipeline and its production, can solve the problems of poor thermal insulation performance, easy corrosion and leakage of pipelines, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

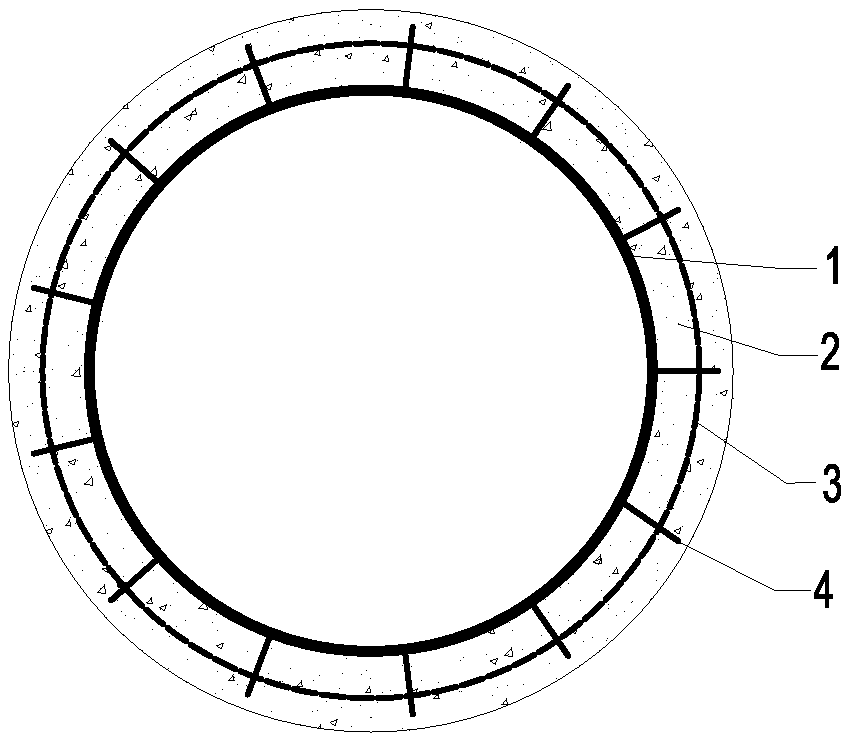

[0032] refer to figure 1 , a UHPC-SS composite pipeline, which consists of: a stainless steel inner pipe 1, a UHPC concrete layer 2 is poured on the outside of the stainless steel inner pipe 1, a steel mesh 3 is arranged in the UHPC concrete layer 2, and the UHPC concrete layer 2 and the stainless steel pipe 1 are provided with shear nails 4, and the shear nails 4 pass through the steel mesh 3.

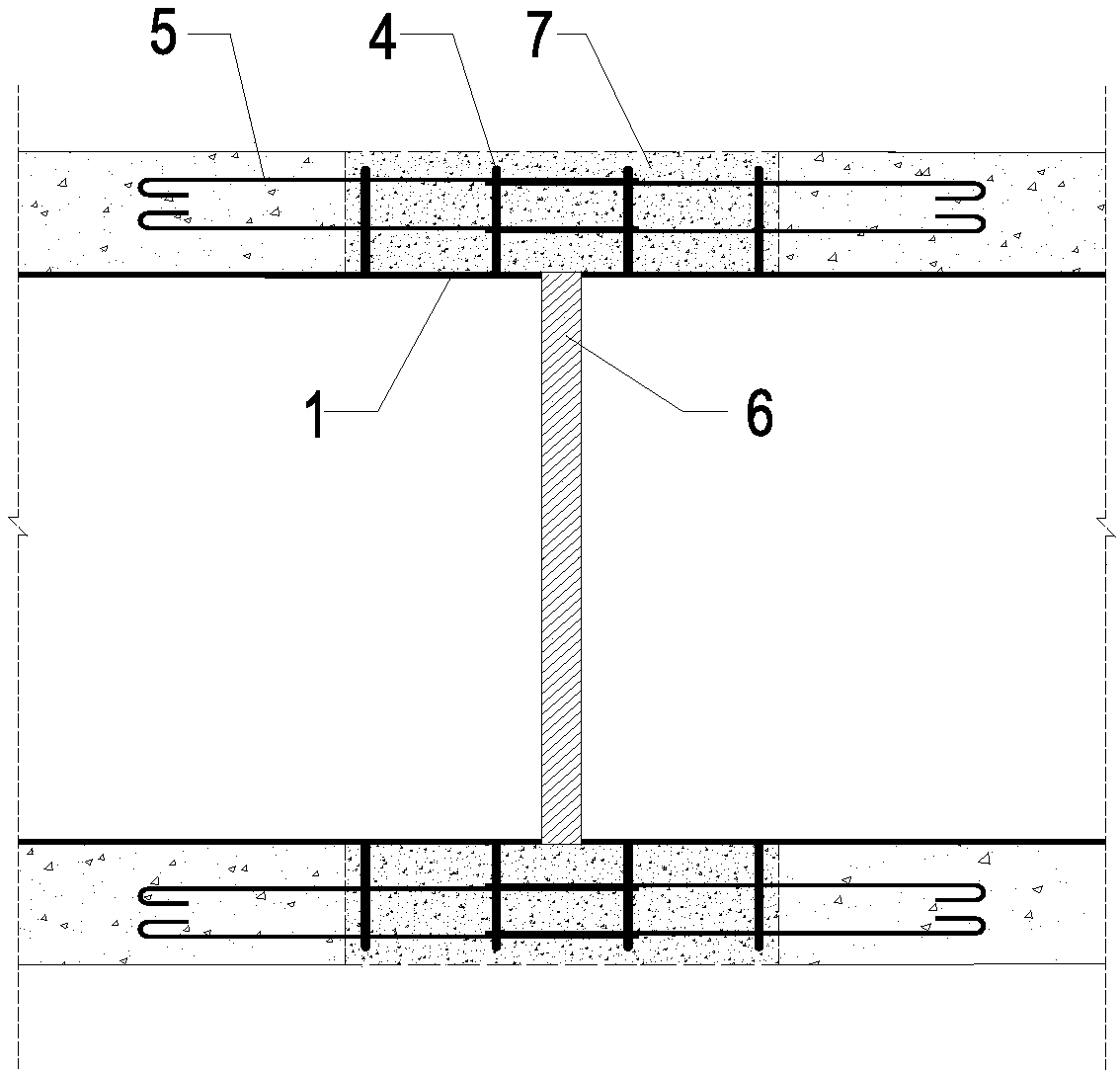

[0033] The stainless steel inner pipe 1 is a 304 stainless steel pipe with a wall thickness of 1.5mm and an inner diameter of 300mm; the composite pipe is prefabricated in sections, each section length is 5m, and the two ends of the composite pipe are provided with embedded steel bars 5 for structural joints and Stainless steel inner tube 1.

[0034] refer to figure 2 , the structural joints of this embodiment adopt cast-in-place pipe joints. After the composite pipes on the installation site are positioned to a predetermined position, the pre-embedded steel bars 5 at the joints of...

Embodiment 2

[0043] refer to figure 1 , a kind of UHPC-SS composite pipeline, and its composition comprises: stainless steel pipe 1, the outside of described stainless steel pipe 1 is poured with UHPC concrete layer 2, has reinforcing mesh 3 in described UHPC concrete layer 2, described UHPC concrete layer 2 and stainless steel There are shear nails 4 between the steel pipes 1 , and the shear nails 4 pass through the reinforcement mesh 3 .

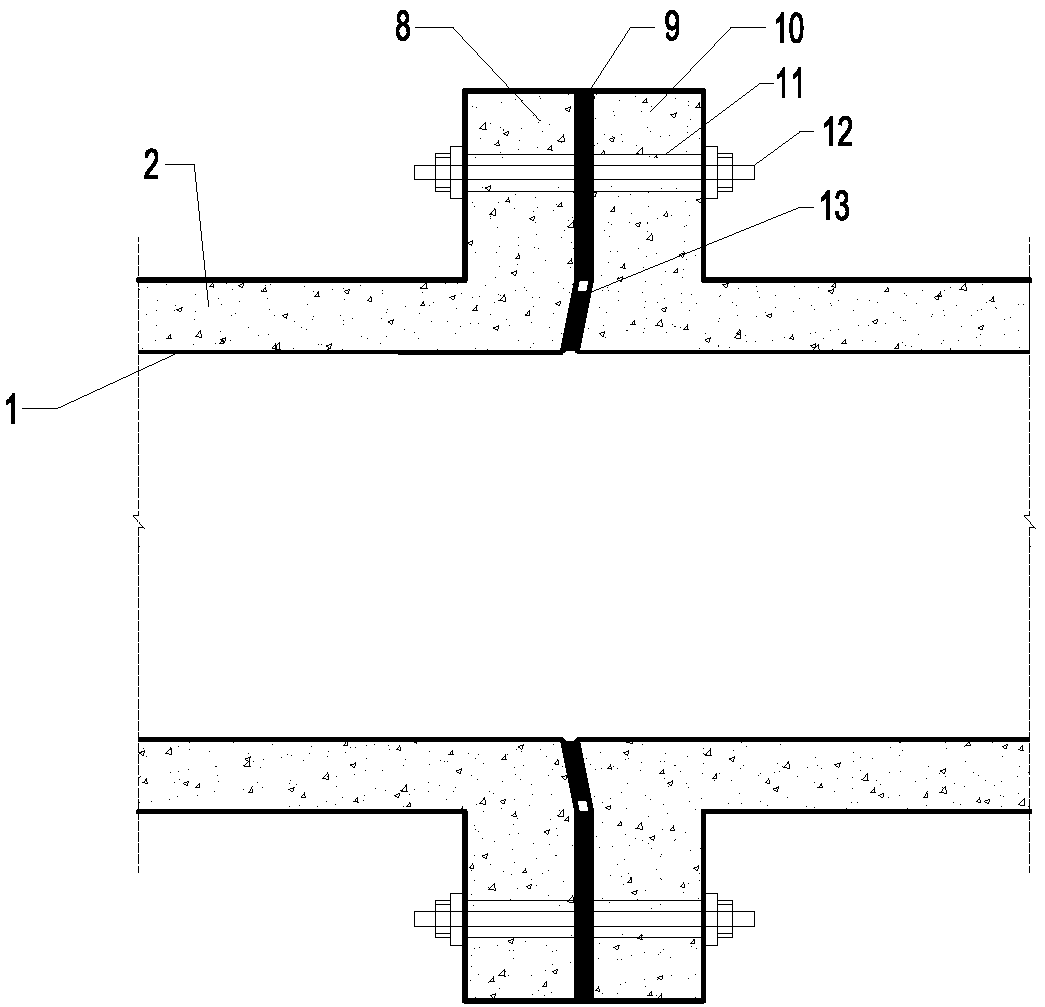

[0044] The stainless steel inner pipe 1 is a 304 stainless steel pipe with a wall thickness of 1.5mm and an inner diameter of 300mm; the composite pipe is prefabricated in sections, each section is 5m in length, and both ends of the composite pipe are provided with concave flanges for structural joints 8 or convex flange 10, the concave flange 8 and convex flange 10 are prefabricated by UHPC concrete and composite pipes, and are provided with reserved holes 11.

[0045] refer to image 3 , The structural joint of this embodiment adopts an assembled p...

Embodiment 3

[0051] refer to figure 1 , a kind of UHPC-SS composite pipeline, and its composition comprises: stainless steel pipe 1, the outside of described stainless steel pipe 1 is poured with UHPC concrete layer 2, has reinforcing mesh 3 in described UHPC concrete layer 2, described UHPC concrete layer 2 and stainless steel There are shear nails 4 between the steel pipes 1 , and the shear nails 4 pass through the reinforcement mesh 3 .

[0052] The stainless steel inner pipe 1 is a 304 stainless steel pipe with a wall thickness of 1.5mm and an inner diameter of 300mm; the composite pipe is prefabricated in sections, each section length is 5m, and the two ends of the composite pipe are provided with flanges 16 for structural joints and Stainless steel inner tube 1. refer to Figure 7 , the flange 16 is prefabricated by UHPC concrete and composite pipes, and is provided with a reserved hole 11 .

[0053] refer to Image 6 , the structural joint of this embodiment adopts the grouting ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com