Prefabricated beamless floor composite slab based on stress and disassembly method thereof

A beamless floor, laminated board technology, applied in the direction of floors, structural elements, building components, etc., can solve the problems of complex use, no specific solutions, difficult to control, etc., to improve strength and rigidity, and reduce design thickness. The effect of the amount of reinforcement and the promotion of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

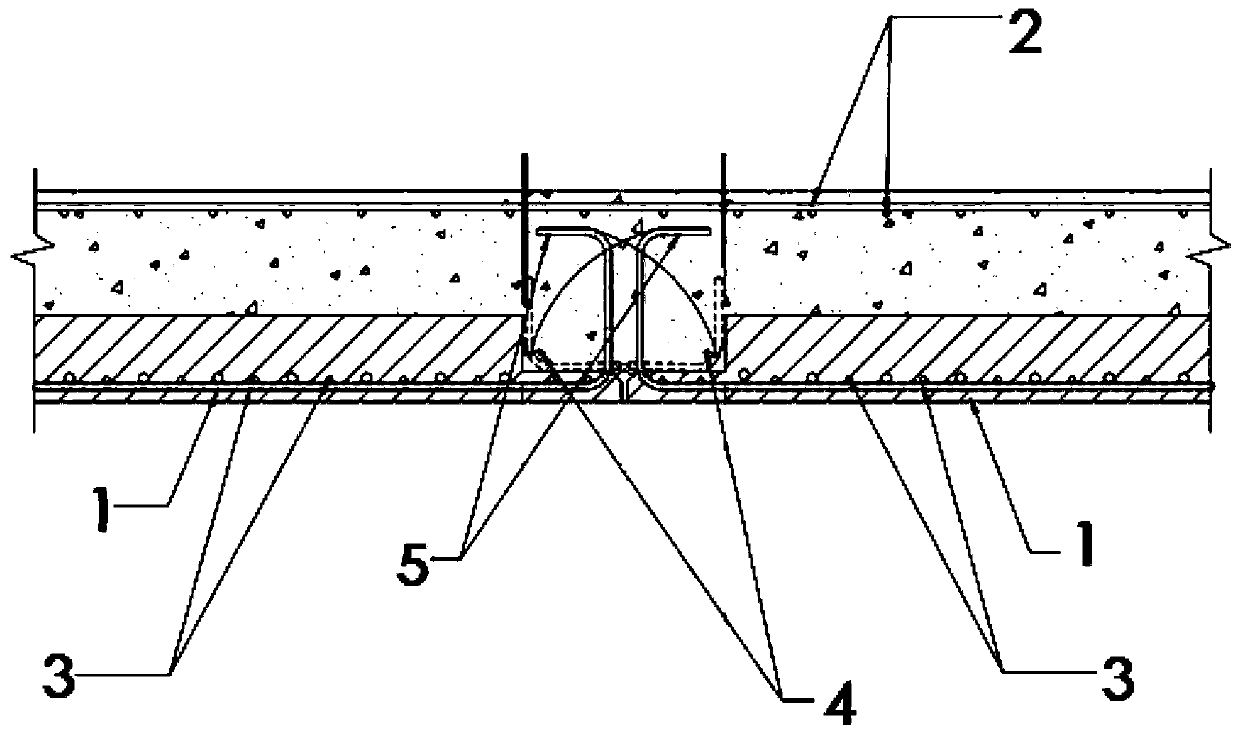

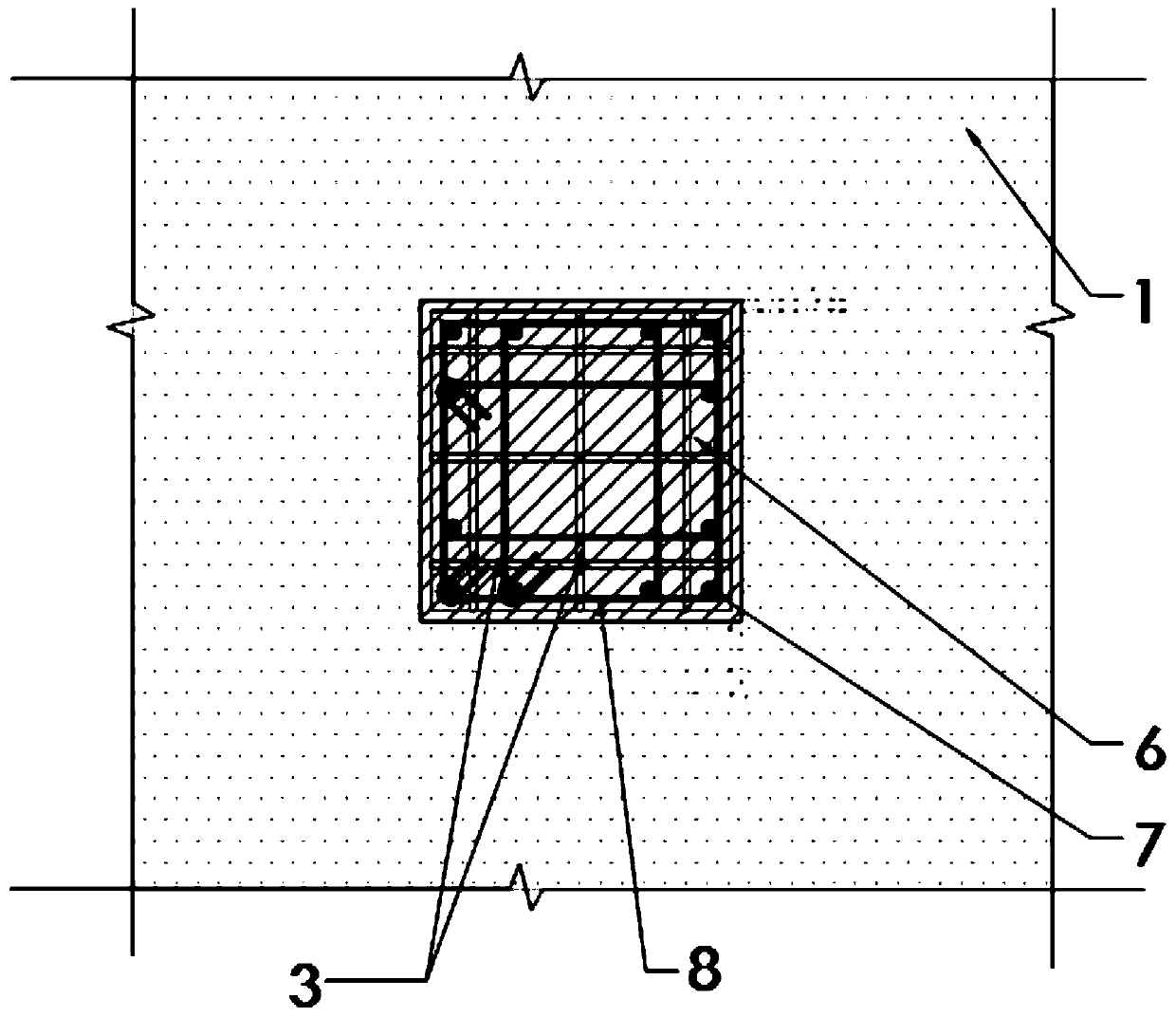

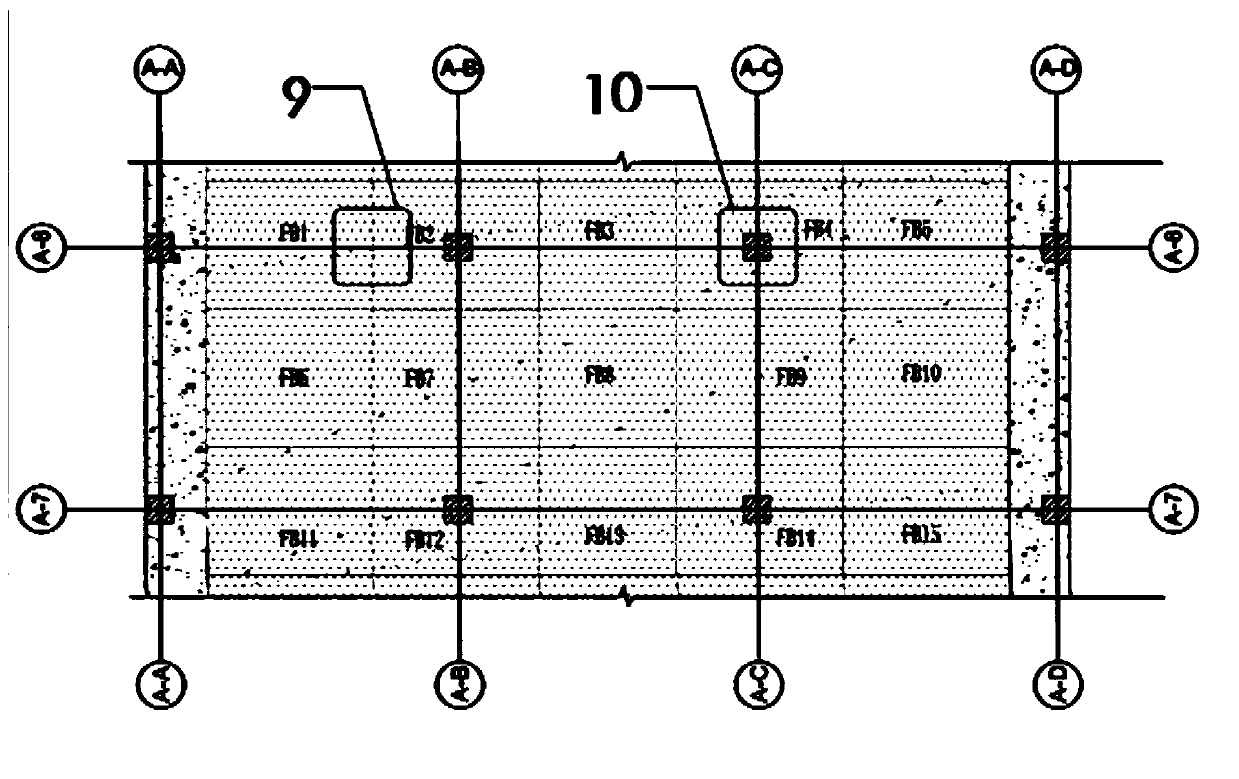

[0033]A force-based prefabricated beamless floor composite slab, including a connection node between a prefabricated composite floor and a prefabricated column, and a connection node between a prefabricated composite floor and a prefabricated column, and the connection node between the prefabricated composite floor and a prefabricated column includes a prefabricated composite floor Enter into the protective layer of the prefabricated column, keep the reinforcement continuous with the prefabricated column, and bind the stirrup of the prefabricated column; the connection node of the prefabricated laminated floor includes a cast-in-place layer and a prefabricated laminated floor layer, and the cast-in-place There are floor ribs stacked vertically in each floor; floor bottom ribs vertically stacked in the prefabricated laminated floor, and the end parts of the prefabricated laminated floor are groove-shaped and connected by tongue-and-groove. The protruding ribs formed by bending t...

Embodiment 2

[0038] A force-based prefabricated beamless floor composite slab, including a connection node between a prefabricated composite floor and a prefabricated column, and a connection node between a prefabricated composite floor and a prefabricated column, and the connection node between the prefabricated composite floor and a prefabricated column includes a prefabricated composite floor Entering into the protective layer of the prefabricated column, keeping the steel bar continuous with the prefabricated column, and binding the stirrup of the prefabricated column; the connection node of the prefabricated laminated floor includes a cast-in-place layer and a prefabricated laminated floor layer; and the prefabricated laminated floor After the composite floor slab and the prefabricated column and the prefabricated composite floor slab and the prefabricated composite floor slab are installed separately, steel bars are bound on the surface layer to form a reinforcement mesh; the prefabric...

Embodiment 3

[0051] A force-based prefabricated beamless floor composite slab, including a connection node between a prefabricated composite floor and a prefabricated column, and a connection node between a prefabricated composite floor and a prefabricated column, and the connection node between the prefabricated composite floor and a prefabricated column includes a prefabricated composite floor Entering into the protective layer of the prefabricated column, keeping the steel bar continuous with the prefabricated column, and binding the stirrup of the prefabricated column; the connection node of the prefabricated laminated floor includes a cast-in-place layer and a prefabricated laminated floor layer; and the prefabricated laminated floor After the composite floor slab and the prefabricated column and the prefabricated composite floor slab and the prefabricated composite floor slab are installed separately, steel bars are bound on the surface layer to form a reinforcement mesh; the prefabric...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com