Steel-PVA fiber toughness concrete combined bridge deck structure and construction method thereof

A technology of fiber toughness and combined bridge deck, which is applied in the direction of bridges, bridge parts, bridge construction, etc., to achieve the effects of improving durability and impermeability, convenient construction, good operability and economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Embodiments of the present invention will be specifically described below in conjunction with the accompanying drawings, wherein the accompanying drawings constitute a part of the application and are used together with the embodiments of the present invention to explain the principles of the present invention.

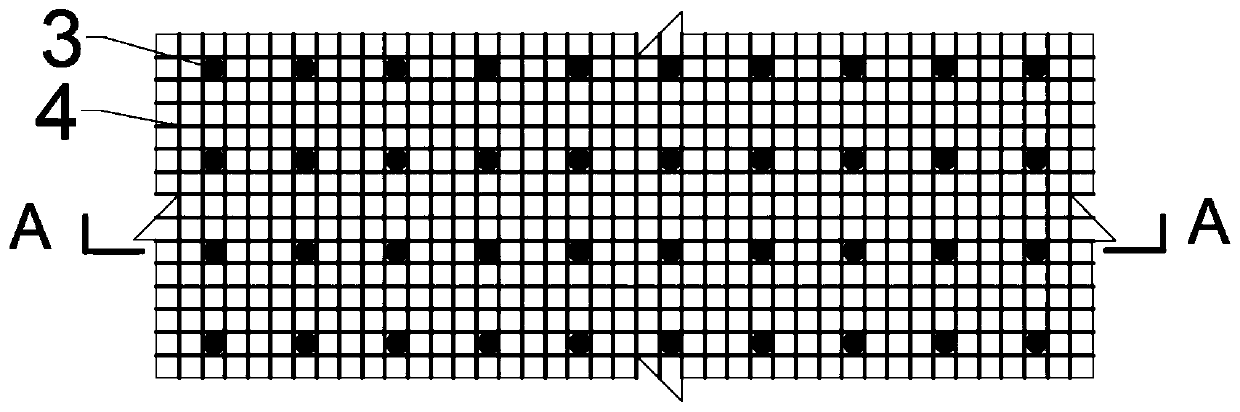

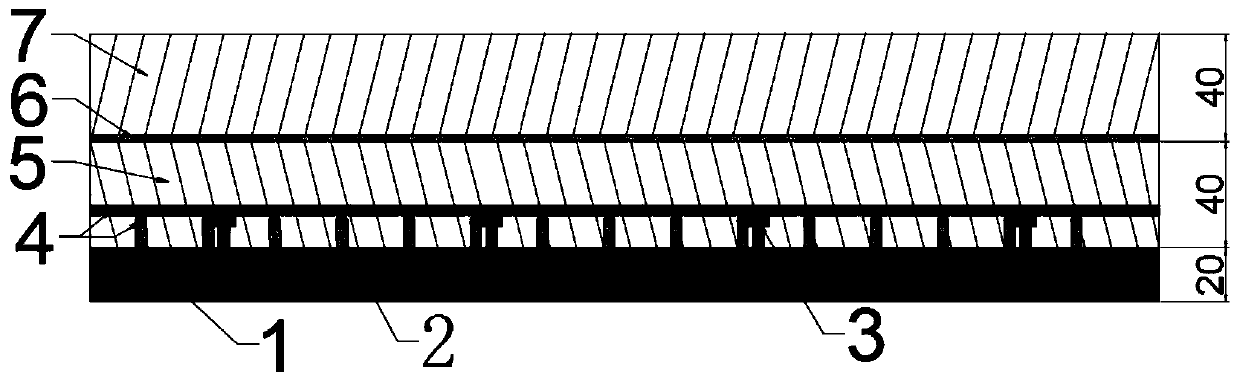

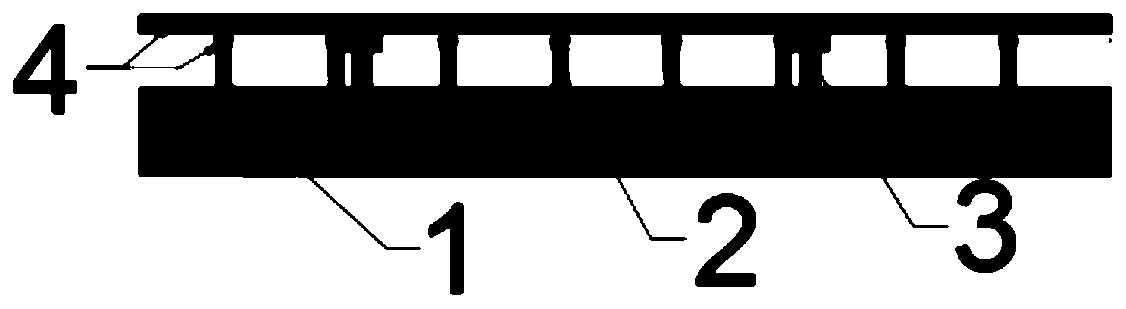

[0043] Legend: 1 Steel bridge deck layer (20mm thick); 2 Neoprene pads; 3 Shear studs; 4 Steel mesh; 5 PVA fiber ductile concrete layer (40mm thick); 6 Adhesive layer; 7 Asphalt concrete surface (Thickness 40mm). The connection structure of this embodiment is as figure 1 , figure 2 , image 3 Shown: Prefabricate, assemble, and weld steel girders in sequence according to the conventional steel bridge construction method until the construction of steel bridge deck layer 1 is completed; sandblasting and derusting treatment is carried out on the steel bridge deck whose construction meets the design requirements, and the shear bolts are welded nails 3, and then p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com