Machining method of metallurgical furnace launder

A processing method and metallurgical furnace technology, applied in the processing field of metallurgical furnace launders, can solve the problems of low strength of red copper or alloy copper, thick thickness of buried pipe casting body, affecting the normal production of metallurgical furnace, etc., and achieve excellent cooling effect and saving. Purchase cost, effect of grain refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

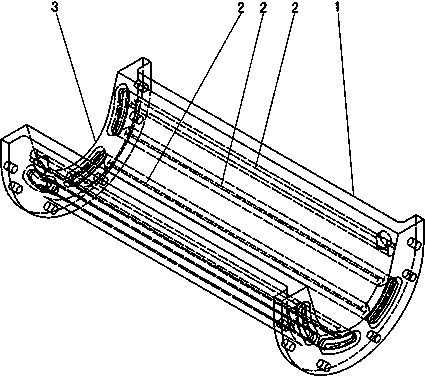

[0032] The processing method of the metallurgical furnace launder of the present embodiment is processed by combining forging slab and machining, including the following steps:

[0033] a. Forging the cast slab into semi-finished metallurgical furnace launder with curved surface;

[0034] b. Finishing the semi-finished products of metallurgical furnace launder components into finished metallurgical furnace launders.

[0035] The material of the cast slab is red copper or alloy copper.

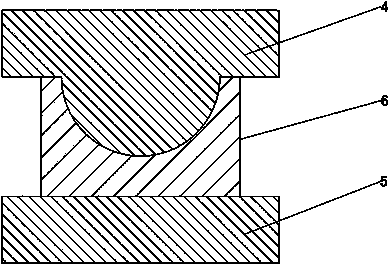

[0036] Such as figure 2 As shown, the forging is to forge and press the cast slab by a hydraulic press, and the thickness of the cast slab is twice the thickness of the finished product after forging; ≥98%IACS, corresponding thermal conductivity: λ≥381W / (m·K).

[0037] The finishing steps include:

[0038] b1. Use a special deep hole drilling machine tool to drill holes on the semi-finished product of the forged metallurgical furnace launder (processed into a cooling channel pass). The li...

Embodiment 2

[0043] The difference between the metallurgical furnace launder finished product and embodiment 1 in the present embodiment is:

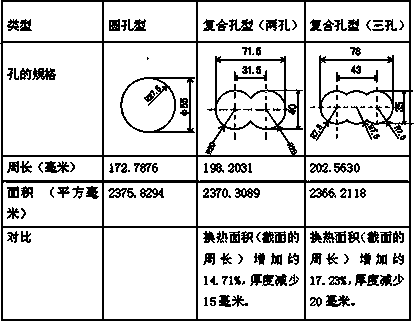

[0044] The cooling water channel 2 is a composite hole, and the composite hole is partially overlapped by two circular holes. The diameter of each circular hole is the same, and the heat exchange area (perimeter of the section) of the cooling water channel increases by about 14.71%.

Embodiment 3

[0046] The difference between the metallurgical furnace launder finished product and embodiment 1 in the present embodiment is:

[0047] The cooling water channel 2 is a composite hole, and the composite hole is partially overlapped by three circular holes. The diameters of the circular holes are different, and the heat exchange area (perimeter of the section) of the cooling water channel increases by about 17.23%.

[0048]Taking a finished metallurgical furnace launder with a length of 2m and an unfolded width of 1.5m as an example, in order to meet the performance requirements and life requirements of the traditional casting process, the thickness of the launder is usually designed to be more than 160mm. Thickness above 120mm (including 120mm) can meet the requirements. For the slab with the above compound pass type (three holes), under the condition of ensuring the same wall thickness of the cooling channel, one round hole (such as Φ55) is changed to three round holes supe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com