Friction pair system of double clutch

A dual clutch and friction pair technology, applied in the clutch field, can solve problems such as poor clutch heat dissipation, and achieve the effects of avoiding high temperature failure, shortening axial length, and reducing heat dissipation burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

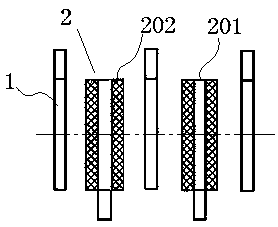

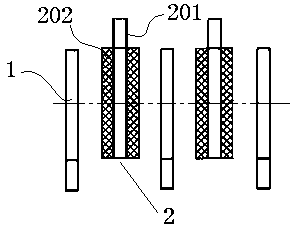

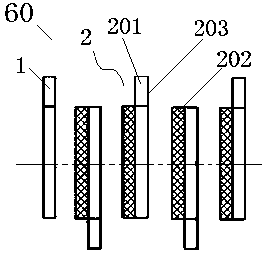

[0013] The present invention will be further described below with reference to the accompanying drawings and examples. see Figure 3 to Figure 4 , a dual-clutch friction pair system, including a dual plate 1 and a friction plate 2, the steel bracket 201 of the friction plate 2 is mounted with a friction material 202 on one side, and the other side is a smooth surface 203; the dual plate 1 The friction plates 2 are arranged in sequence on one side, and the side of the friction plate 2 equipped with the friction material 202 is all facing the side of the dual plate 1; the steel plate bracket 201 of the former plate is directly in contact with the friction material 202 of the latter plate, and the The heat generated by friction is dissipated.

[0014] The dual-clutch friction pair system of the present invention only includes a dual plate 1 and a multi-plate friction plate 2 structure. The dual sheet 1 is a steel sheet structure, which provides a mating friction element for the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com